What would you do if you had a new C-note, a genuine Benjamin burning a hole in your pocket and you wanted to buy a new budget pocketknife? Would you know which to pick? Do you know what blade steel to get?

Yes, buying a new knife can be a lot more complicated than a basic impulse buy of a crappy, cheap, gas station design, but there’s also more to consider than just a scientific review of blade steels metallurgy. Now I can’t help you with your own, unique aesthetic preferences, your specific brand loyalties, or any potential penchant for features like garbage blade coatings, handles with bizarre colors and cheap, flaky paint coatings, crazy-shaped, deeply uncomfortable knife handles emblazoned with flames, flying bats, dragons, skulls and snakes, along with all the other useless crap that comes on gas station knives.

But I can talk with you about blade materials, and how, if you are going to spend some hard-earned bucks on a new knife, not to buy a crap blade. So I will! There’s a lot of hot garbage out there from vendors who are more than willing to take your greenbacks in exchange for a rubbish, folding blade knife. But with the same cash, you can also buy a budget knife with several types of reasonably impressive blade steels that will serve you well as a cutting tool (that specifically excludes Goth, Steampunk, or just some oddball show pieces that, if ever put into action as a knife for cutting, might actually fall apart in your hands and cut you!).

I originally wrote this as one grandiose, e-friggin’-normous post. But as it nearly broke my website, I had to break it up into 3 pieces. Bloody WordPress. Here’s what I have for you:

- The first post (which you are reading now) discusses the inventory of all the budget blade steels I scraped from the websites of a large number of online pocketknife retailers. I also discuss they many blade steel performance factors that you should know about before shopping for your next knife (budget or not!). It’s a gonzo blade steel geek-out!

- Part 2 will begin the process of examining the 3 categories I created for organizing the retailer inventory of budget blade steels: Decent, Mediocre, and Junk. Yep, I said it. This post will only cover the Decent steels.

- Part 3 will dive into both the Mediocre and the Junk blade steels. I also look at both the weird and the unexpected steels I found in the Budget category.

So let’s dig into this, define our terms, explain key concepts, check what’s on the market today, review blade steel performance factors, and provide you with some food for thought on what you should be looking for (and what to avoid) in a budget folding knife blade.

TL;DR

A budget knife need not be a gas station junker. Those have their place (I suppose), but if you don’t have the cash on hand to pick up a new Polish Herman knife (sadly, I know I don’t), and you actually want a working knife to use (which then rules out gas station knives), brushing up on your blade stock background info will help you get the most for your precious spending money.

Pros

- There are some reasonably good performing knife blade steels available in the Budget category. Nothing that will blow you away, but with some careful shopping, you can get a knife that should serve you pretty well – as long as you only use it to cut stuff. Basic stuff. But do not screw around with it, do not pry into someone’s business, and for the love of all that is good and just, don’t run a baton race with these blade steels on pocketknives!

- There are a huge number of knife blade material used in the Budget category, so you have a lot of choices, assuming what you want it actually in stock.

- Learning about blade performance factors can help you choose the right knife for what you want to do.

Cons

- Many online pocketknife retailers (58% of all those I visited) have genuinely crappy websites. They don’t allow you to filter your searches for pocketknives by price, blade materials, or many other properties that are important to knife shoppers (and me!).

- Some retailers do a very poor job of identifying the blade materials they sell. Many list a large percentage of their inventory simply as “stainless”, which is meaningless, given the huge expanse of stainless steels available. Some even list a few blade materials as “Unknown”! WTF? Are you guys even trying?

What’s Out There?

For you, my loyal readers (all six of you!), I conducted an analysis of what’s available for purchase from a large number of online knife retailers. I filtered my searches down to just folding knives. I also kept the search within the range of a budget knife. My goal was to find sites that had a large pocketknife inventory where I could narrow my search down to folding knives and narrow to the list to those knives hat cost less than a Big Benjamin, a C Note, you know what I’m saying here, right?

Budget Knife?

So what is a budget knife? Well, it’s whatever you want it to be. I know that some folks, such as Metal Complex, define a budget knife to be priced under $75. But he’s used that price for a long time. Have you been hearing about this thing called inflation over the past several years? Yeah, me, too. While I don’t know if inflation has devalued the spending value of the American Dollar to be total crap, I do know that we can’t buy as much as we used to be with a dollar. You need more of them to buy stuff! So since I started my blog earlier this year, I have been using the lowest cost knife tag to be <$100. So I’m calling any knife that can be bought for under $100 in 2024 to be a “budget” knife. Yeah, that seems steep, but have you seen the price of cars or houses or Herman Knives recently? Stuff’s getting expensive! If you really object top that level, then that’s cool. You can go start-up your own blog and I may or may not read it (I hope you know how to do SEO!). But in SharperApex, less than $100 is budget territory.

Retailers, Retailers, and more Retailers

Earlier this fall, I researched who were the largest, most favored online knife retailers on the InterTubes. I used Google, BladeForums, and other online knife resources to find where people liked to shop online for their slicers. I found and rustled through 40 online retail websites before I decided I had had enough! However, of the 40, a shockingly high 23 of them were not worthy of my time to continue doing my research there. There were several, repeated thematic reasons for this. This is what I found:

| Rejected Retailers | Reason for Rejection |

|---|---|

| Atlantic Knife | No blade steel filter |

| BladeOps | No blade steel filter |

| Blue Ridge Knives | Poor site search filters |

| Country Knives | No blade steel filter |

| Cranes Cutlery | Poor site search filters |

| Cutlery Shoppe | No blade steel filter |

| Edgeworks | Poor site search filters |

| eKnives | No blade steel filter |

| Going Gear | Poor site search filters |

| House of Blades | Very limited inventory |

| Knife Market | Very limited inventory |

| Master Cutlery | Poor site search filters |

| NC Blade | Poor site search filters |

| Plaza Cutlery | Poor site search filters |

| PVK | Poor site search filters |

| Red Hill Cutlery | Poor site search filters |

| Rivers Edge Cutlery | No blade steel filter |

| Sheppard Hills Cutlery | Very limited inventory |

| St. Nick's Knives | Poor site search filters |

| The Knife Connection | Very limited inventory |

| Urban EDC | Poor site search filters |

| Walmart | No blade steel filter |

| Willey Knives | Poor site search filters |

This is not to say that these retailers do not offer good deals or carry poor products. Some of these sellers are beloved in the community! All I’m saying is that their crummy websites did not contribute to the effort I was trying to make, which is to analyze the budget knife market to see which types of blade steels are being sold within the specified price range, and in what proportions. That all said, each one of these sites would benefit from a serious revamp of their inventory search capabilities. When you make it hard for customers to find what they want to buy on your site, they will move along and shop elsewhere on websites that have already resolved that problem. Cheaping out on minimal website features genuinely hurts your bottom line! Wake up, people!

I did find 17 online retailers that did have a reasonable (or better!) inventory selection AND provide inventory search filters I needed to collect my data, such as blade material and purchase price. Most even gave me the number of knives they had per blade type (a few did not, but being the detailed analytics freak that I am, I manually counted those listings for each blade material listed from those barely qualified retailers). Here’s what I gathered for sellers of folding knives for under $99:

| Sellers | Quantity |

|---|---|

| BladeHQ | 9,735 |

| Smoky Mountain Knife Works | 6,649 |

| Chicago Knife Works | 5,712 |

| KnifeCenter | 5,677 |

| GPKnives | 3,322 |

| Knives and Tools | 2,562 |

| KnifeWorks | 2,269 |

| Knives Plus | 1,909 |

| Heinnie Haynes | 1,708 |

| DLT Trading | 1,231 |

| White Mountain Knives | 668 |

| AG Russell | 462 |

| Knife Depot | 451 |

| Knife Joy | 275 |

| New Graham Knives | 214 |

| Cabelas | 172 |

| Knives Ship Free | 85 |

| TOTAL: | 43,101 |

Did any of you know that Chicago Knife Works had a bigger pocketknife inventory than KnifeCenter? I didn’t, either! Did any of you know that BladeHQ had such a significantly larger inventory than everyone else? Hmmm.

Now truth be told, these are not close to being apples-to-apples comparisons. The inventory search for some retailers gave individual listings each knife model, and when a model came in multiple configurations for blade shape, handle material, coatings, and more, every one of those got an individual listing. Other sites only counted a given model as single listing, regardless of the various configurations within the model. So whatever. This analysis sucks. Maybe all the earlier size matters comparison comments are garbage, too. But collecting the precise retailer inventory view was not the primary goal of this exercise. Instead, it simply set the stage for what I wanted to analyze: budget blade steel types. I suppose the numbers of blade materials for sale per retailer is similarly affected by the lack of inventory consistency between retailers. So whatever. Let’s proceed.

Budget Blade Materials

So the number of budget knives I captured was only a modest sum, a mere 43K. But what I captured here was more interesting – and frustrating, again, due to the crappy inconsistency of how many retailers catalog their knife blade materials. Of the 185 unique blade materials listed, the 2nd highest variety was identified as “Stainless Steel”. Seriously. Of course, the vast majority of pocketknife steels are in fact stainless, but most of the time it was broken out into the many different varieties of stainless steel. So this means that either the retailers didn’t know what they were selling, or they didn’t care to bother identifying the types of blade materials on the knives in their inventories.

When I first saw the raw data, I had collected, it was ridiculous to see that in at least 1 case, over a quarter of all the knives they listed for sale were attributed to the useless description of “Stainless Steel”. The retailers that identified a portion of their budget knife steel inventory as generic stainless are below (and the Hall of Shame are listed in red, as these companies are not doing their jobs compared to others in green):

| Sellers | All | "Stainless" | % of All |

|---|---|---|---|

| Chicago Knife Works | 5,712 | 1,538 | 26.93% |

| Knife Depot | 451 | 68 | 15.08% |

| BladeHQ | 9,735 | 1,349 | 13.86% |

| Smoky Mountain Knife Works | 6,649 | 908 | 13.66% |

| Heinnie Haynes | 1,708 | 186 | 10.89% |

| DLT Trading | 1,231 | 114 | 9.26% |

| KnifeCenter | 5,677 | 243 | 4.28% |

| Knives and Tools | 2,562 | 76 | 2.97% |

| KnifeWorks | 2,269 | 64 | 2.82% |

| AG Russell | 462 | 7 | 1.52% |

| GPKnives | 3,322 | 50 | 1.51% |

| Knife Joy | 275 | 3 | 1.09% |

| White Mountain Knives | 668 | 3 | 0.45% |

But I was undeterred. I needed to know what all that mislabeled crap was in order to produce a decent analysis of the market. So I opened up the searches for the most egregious offenders and hacked away at it, bit by bit, properly reclassifying the knife blades when I recognized the knife models when I could reasonably do so. Were mistakes made? You bet! But is it better than it was fresh off the original web scrape inventory? Hells yes!

So what did I find? Here’s the whole bloody list, rolled up into 3 columns, and cleaned up quite a bit. Please do remember the caveat of this not being a clean, apples-to-apples listing, but it’s the best I could do over the course of a few days’ work. Remember this is over 17 retailers with a restriction that the knives had to be under $100.

| Blade Material | Quantity | Blade Material | Quantity | Blade Material | Quantity | ||

|---|---|---|---|---|---|---|---|

| D2 | 6,501 | 7Cr | 37 | Unknown | 6 | ||

| 8Cr13MoV | 3,719 | SK5 | 37 | X50CrMoV15 | 6 | ||

| Stainless | 3,321 | 3G | 36 | 5Cr13 | 5 | ||

| Tru-Sharp | 3,022 | Plastic | 35 | 8Cr15MoV | 5 | ||

| 14C28N | 2,838 | 154 | 33 | Acuto 440 | 5 | ||

| 440 | 1,632 | 3V | 31 | Super Blue | 5 | ||

| 440A | 1,386 | H2 | 31 | N680 | 5 | ||

| 154CM | 1,211 | Ceramic | 30 | HAP40 | 5 | ||

| 7Cr17MoV | 1,183 | C70 | 28 | 13C26 | 4 | ||

| VG 10 | 1,138 | Nitrox | 28 | 3Cr | 4 | ||

| AUS 8 | 1,055 | M390MK | 26 | 4Cr14MoV | 4 | ||

| Nitro V | 998 | Sleipner | 26 | 6Cr12 | 4 | ||

| 420 | 885 | C67 | 25 | 6Cr12MoV | 4 | ||

| 12C27 | 851 | 9Cr13MoV | 24 | 8Cr14 | 4 | ||

| 9Cr18MoV | 839 | LC200N | 24 | 8Cr18MoV | 4 | ||

| 1095 | 728 | M-VX | 23 | 9Cr13 | 4 | ||

| Damascus | 727 | 8CR13 | 21 | O1 | 4 | ||

| 440C | 617 | 5Cr13MoV | 20 | Titanium | 4 | ||

| 420HC | 603 | ATS 55 | 20 | 425 | 3 | ||

| N690 | 600 | S90V | 19 | 420J | 3 | ||

| 3Cr13 | 556 | Elmax | 19 | 8Cr12MoV | 3 | ||

| S35VN | 476 | CRU-WEAR | 18 | 9Cr18 | 3 | ||

| 4110 | 460 | PD-1 | 18 | M398 | 3 | ||

| Carbon Steel | 454 | 9Cr13CoMoV | 15 | Rex 121 | 3 | ||

| Z40C13 | 441 | BECUT | 15 | Rex 45 | 3 | ||

| 4116 | 421 | M4 | 14 | CS80 | 3 | ||

| AR-RPM9 | 404 | San Mai | 14 | Niolox | 3 | ||

| 420J2 | 400 | White Steel | 14 | SK2 | 3 | ||

| 8Cr14MoV | 345 | 1065 | 13 | 420C | 2 | ||

| S30V | 309 | AUS 4 | 13 | 9Cr | 2 | ||

| AUS 8A | 283 | V-Toku2 | 13 | 9Cr17 | 2 | ||

| AUS 10A | 282 | 10Cr15MoV | 12 | Acuto+ | 2 | ||

| 3Cr13MoV | 267 | ATS 34 | 12 | AEB-L | 2 | ||

| AUS 10 | 247 | 10V | 12 | Aluminum | 2 | ||

| K110 | 242 | 4V | 12 | N695 | 2 | ||

| High Carbon | 221 | SPY27 | 12 | Carbon Fiber | 2 | ||

| M390 | 206 | XC90 | 12 | GIN 1 | 2 | ||

| 4034 | 202 | 5Cr14 | 11 | K5 | 2 | ||

| S45VN | 186 | 400 | 10 | SG2 | 2 | ||

| 20CV | 141 | 1095HC | 10 | T12 | 2 | ||

| 8Cr | 133 | 15N20 | 10 | Vanadis 4E | 2 | ||

| 10Cr15CoMoV | 124 | S110V | 10 | 304 | 1 | ||

| 5Cr15MoV | 116 | INOX-1-42-MOVA | 10 | 4318 | 1 | ||

| Case Chrome Vanadium | 106 | Laminated Cobalt Steel (CoS) | 10 | 420A | 1 | ||

| N690Co | 101 | Maxamet | 9 | 6137 CV | 1 | ||

| 440B | 87 | 4Cr13MoV | 8 | 65Mn | 1 | ||

| X55CrMo14 | 78 | 6Cr | 8 | 8CrMov | 1 | ||

| MagnaCut | 77 | 440V | 8 | BG 42 | 1 | ||

| T10 | 74 | D2 | 8 | G2 | 1 | ||

| Surgical | 73 | 204P | 8 | 13C27 | 1 | ||

| H1 | 69 | Damasteel | 8 | SG3 | 1 | ||

| 4Cr14 | 63 | SK | 8 | SG4 | 1 | ||

| Blue Paper | 57 | X90 | 8 | SG5 | 1 | ||

| BD1N | 56 | 4Cr13 | 7 | SG6 | 1 | ||

| BD1 | 54 | 5Cr15 | 7 | SG7 | 1 | ||

| 7Cr17 | 46 | 9cr14MoV | 7 | SG8 | 1 | ||

| K390 | 43 | BDZ1 | 7 | SG9 | 1 | ||

| 7Cr13 | 40 | ZDP 189 | 7 | X42 | 1 | ||

| Wood | 40 | 1075 | 6 | X50CrMoV15N | 1 | ||

| AUS 6 | 38 | 2Cr13 | 6 | XC75 | 1 | ||

| C75 | 38 | 7Cr15 | 6 | Z50CD15 | 1 | ||

| XHP | 38 | 80CrV2 | 6 |

Have you got that? Does that make your budget knife buying decision easier? Yeah, I didn’t think so. So the analysis continues.

Budget Blade Steel Selections for Review

To make this monstrous madness a little bit more palatable, we need to look at the most commonly offered blade steel choices you’ll have as a buyer of a new budget knife. In the case of these steels, the most common steel types typically have a great many analogues in other steel designations. Some steel types are simply identical compositions under different names, so I aggregated those. Many more are extremely similar in their elemental composition and in their feature properties, so there’s another opportunity to aggregate blade steel types. In the end, I narrowed the focus of my analysis down to the following primary blade steels:

- D2

- 14C28N

- VG 10

- 154CM

- N690

- 8Cr13MoV

- Tru-Sharp

- 9Cr18MoV

- 440C

- 440A

- 420

- 4110

- 1095

Yes, there are (literally) dozens upon dozens of other choices I could have made, but these 13 (and their equivalents) account for 31,945 of the 43,101 blade material types I counted, representing just over 73% of the blade types available. I think that’s pretty darned good enough for government work, don’t you agree?

I specifically chose blade steels that represented, in the sub-$100 Budget categories, Decent, Mediocre, and Junk quality. Note that the listings within each family of steels are not ranked by quality but instead ranked by the quantities that appeared in my inventory.

| Blade Steel Family Types | Steel Type | Common Analogue Steel Types | Family Total | Category Total |

|---|---|---|---|---|

| AISI D2 | High Alloy Tool Steel | Bohler K110, Crucible CPM D2 | 6751 | 13,814 |

| Sandvik 14C28N | Stainless Steel | NJ Steel Baron Nitro V, Sandvik 13C26, Udderholm AEB-L | 3,842 | |

| Takefu VG 10 | Stainless Steel | 10Cr15CoMoV | 1,262 | |

| Crucible 154CM | Stainless Steel | Hitachi ATS-34, Crucible CPM 154 | 1,256 | |

| Bohler N690 | Stainless Steel | Bohler N690Co, Bohler N695 | 703 | |

| 8Cr13MoV | Stainless Steel | Aichi AUS 8, 8Cr14MoV, Aichi AUS 8A, 8Cr15MoV | 5,407 | 11,565 |

| Latrobe Case Tru-Sharp | Stainless Steel | Latrobe 420HC | 3,625 | |

| 9Cr18MoV | Stainless Steel | Artisan Cutlery AR-RPM9, Aichi 440B | 1,330 | |

| AISI 440C | Stainless Steel | Aichi AUS 10A, Aichi AUS 10, Carpenter CTS BD1, 9Cr18 | 1,203 | |

| Aichi 440A | Stainless Steel | 7Cr17MoV, 7Cr17, Aichi AUS-6 | 2,615 | 6,566 |

| AISI 420 | Stainless Steel | 3Cr13, 420J2, 3Cr13MoV, Aichi AUS-4, 2Cr13, 420J | 2,130 | |

| 1.411 | Stainless Steel | 1.4116, 5Cr15MoV, X55CrMo14, X50CrMoV15 | 1,081 | |

| 1095 | Carbon Steel | XC90 | 740 |

Note: The steel manufacturing branch of Sandvik AB, the business known as Sandvik Materials Technology, was transferred in 2022 to Sandvik’s wholly-owned subsidiary Alleima, I will be using the name Alleima (Sandvik) in references to steels such as 14C28N and 13C26.

These selections and classifications are bound to get a few people up in arms, raising torches and pitchforks (how very Medieval of you folks. Will you also storm the Tower of London as well?). But lines had to be drawn, and based on the relative strengths of each steel type to perform in a folding pocketknife (not as a fixed blade, not as a machete, not as any infinitesimally small, niche case you might bring up in protest, but as an EDC pocketknife), these are well-reasoned and community-supported positions that I simply borrowed, not invented out of whole cloth. Besides, it’s my blog and The Knife Karen does what she wants!

Blade Steel Performance Factors

Now before I delve into the mystical world of metallurgy and blade steel properties, I want to talk about other facets of the pocketknife blade that can have a disproportionally significant effect on its performance.

Blade Grind Geometry

It occurs to me that I hear a lot of YouTube Knife “experts” say that blade geometry matters. Yes, it does! But they never bother to explain what that is or even why it matters. I’m not talking about dodecahedrons, radii, pi, proofs or the Pythagorean Theorem. Well, not exactly. But I am talking about angles.

First off, we must gratefully acknowledge the immense, educational influence of Dr. Larrin Thomas in the current subject matter discussion of the properties of knife blade steel. Larrin grew up around steel and knife blade due to his famous father, Devin Thomas, a maker of custom, stainless Damascus steel for knife manufacturers, both large and small. He wasn’t even interested in knives initially, but he eventually took an interest in the field when he heard about the difficulties knife makers had in selecting the proper steel to use in their knives, and then how to do a proper heat treatment with those steels. Their challenge was to ensure the blade was hardened enough to keep a long-lasting edge, but not taking hardening too far, which makes the steel become brittle, where any stress on the blade edge will result in edge chipping or even breaking. It was this science facet of the world of steel that was his entrance into the field. Larrin ended up earning his doctorate studying steel metallurgy and materials engineering, and then began working for US Steel. However, he’s always kept the pocketknife world in mind, so he began sharing his knife blade steel knowledge with the community in his blog, KnifeSteelNerds.com (aka KSN). And by the way, he also invented one of the very few steels that was originally intended for use in knife blades, CPM MagnaCut (and less well known, a new culinary knife steel, ApexUltra).

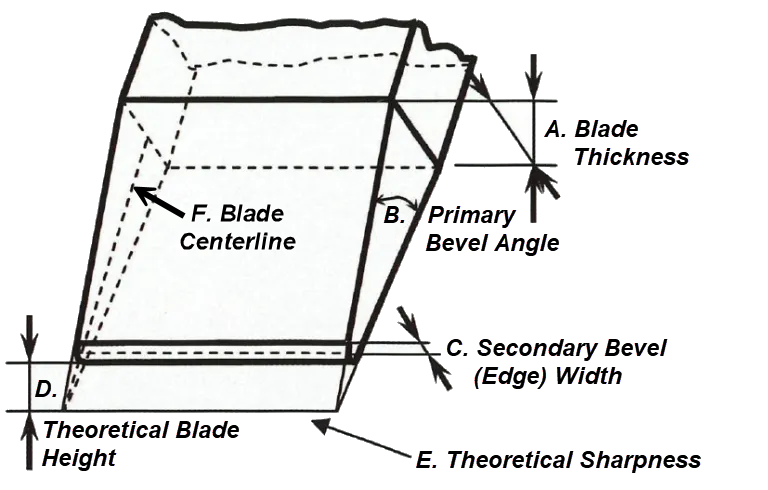

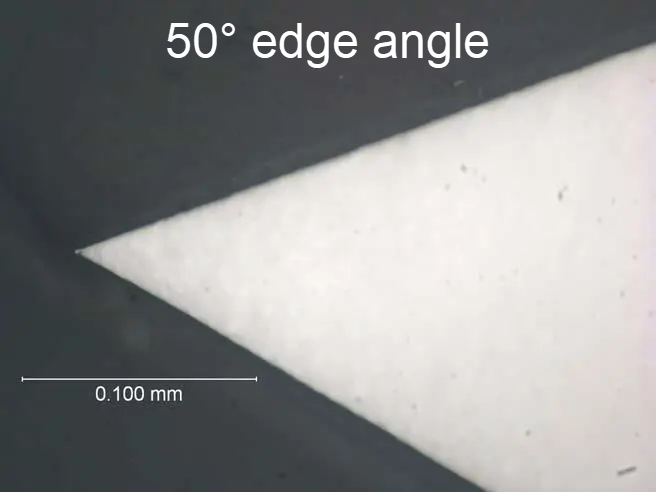

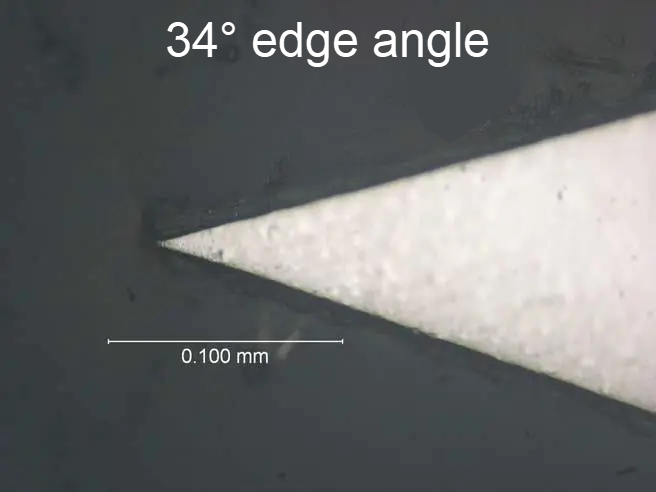

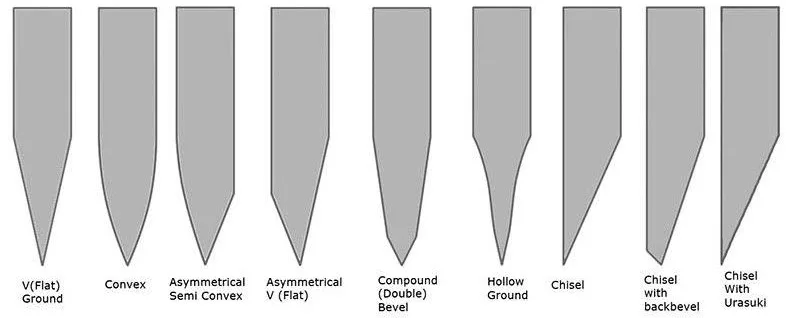

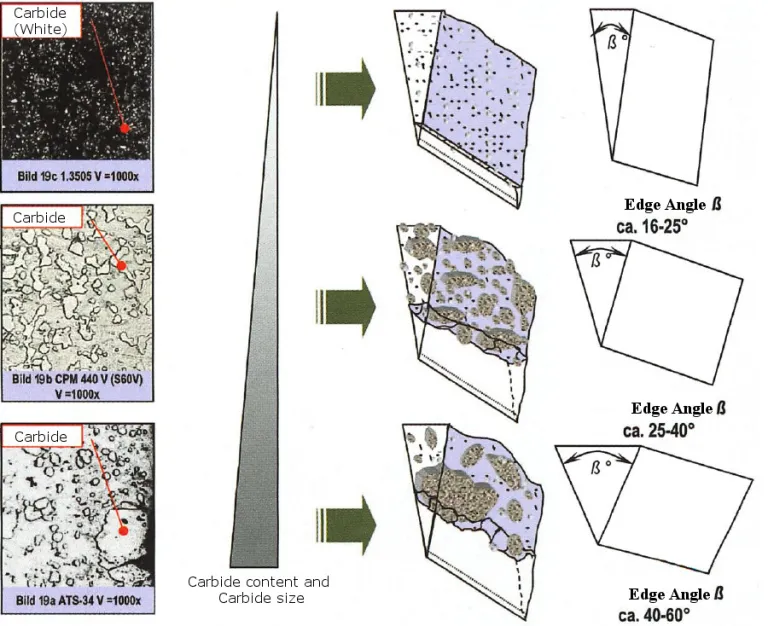

As part of Larrin’s community education on knife steels, he’s written about blade geometry from the perspective of how it affects edge stability. He used this interesting image to detail the geometry of a knife edge.

As he describes it, cross-section A is the full thickness of the blade material as measured at the spine. Section B represents the angle of the primary bevel on a flattened, symmetrically ground blade. Many blades have multiple bevels, so the primary bevel is where the blade stock is ground down from the spine to a theoretical edge. However, if that angle is too acute or shallow, the blade edge geometry will cause many steels to chip or even break away during use. This is especially a concern for steels with lower toughness properties. As such, knifemakers will often add a secondary, less acute, steeper bevel angle as shown above in cross-section C to give the blade steel higher edge durability. Of course, the steeper, secondary bevel shortens the overall blade height shown above in section D from the theoretical blade sharpness as shown at E above as derived from the primary bevel angle. This represents a typical compound bevel blade grind, as opposed to a grind like a Scandi grind, in which the primary bevel is the only bevel. However, on a Scandi grind, it typically begins in the lower half of the blade height, so the primary bevel is less acute than a full flat grind blade would have.

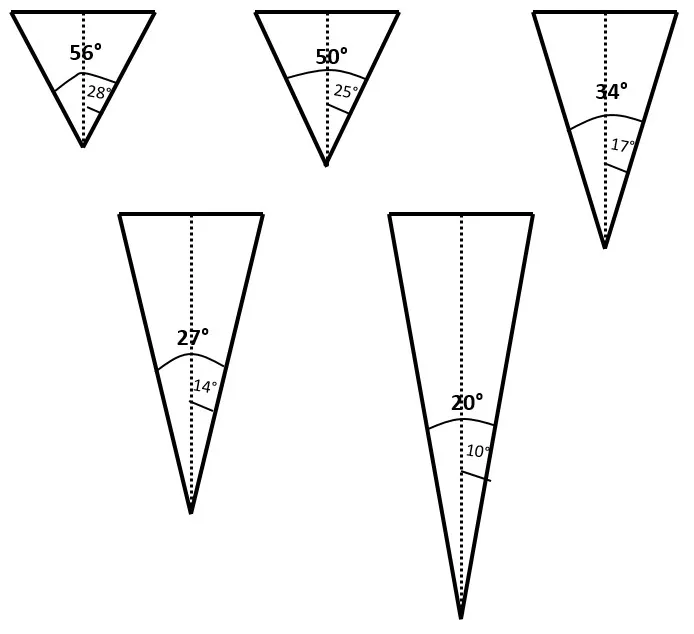

When we think of blade bevel and edge angles, we typically speak of knives being sharpened to perhaps 25° (for outdoor choppers), typically around 17° for pocketknives, and near 10° or so for culinary knives. People think that applies to the B section in the above image. But in truth, those familiar numbers are actually the angles from the blade’s centerline as shown in section F. The entire blade angle, section B, on everything (except a chisel grind, where one side is the straight centerline) is double those section F angles. We can see a clearer illustration of this below.

We technically see a 34° angle on our knives, but we hear that it’s a 17° angle. A true 17° blade angle on a pocketknife would be untenably acute, and the blade edge would quickly either roll over or chip away, either way making it too dull to effectively cut.

Thus, the acuteness of these edge bevel angles makes an enormous difference in not only how sharp the blade can get, but how durable that sharp edge will be in resisting both edge curling (for soft steels) and chipping (for brittle steels).

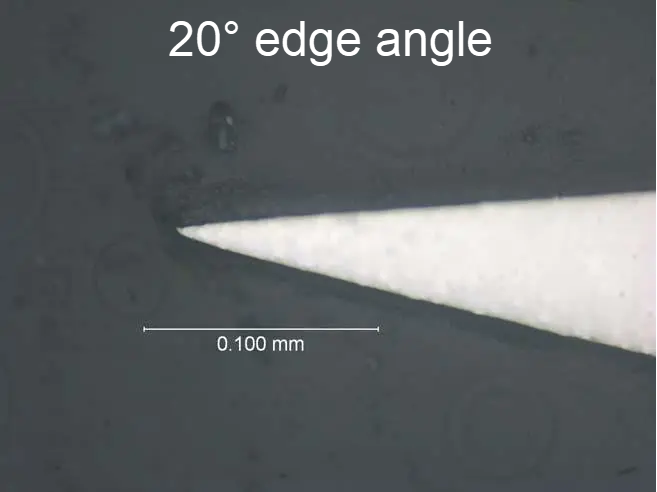

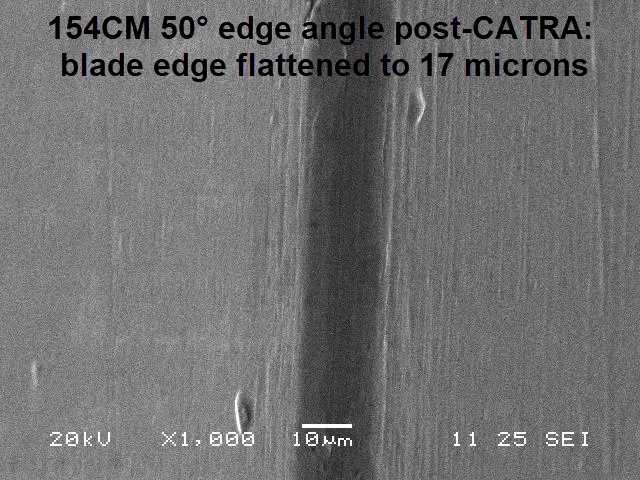

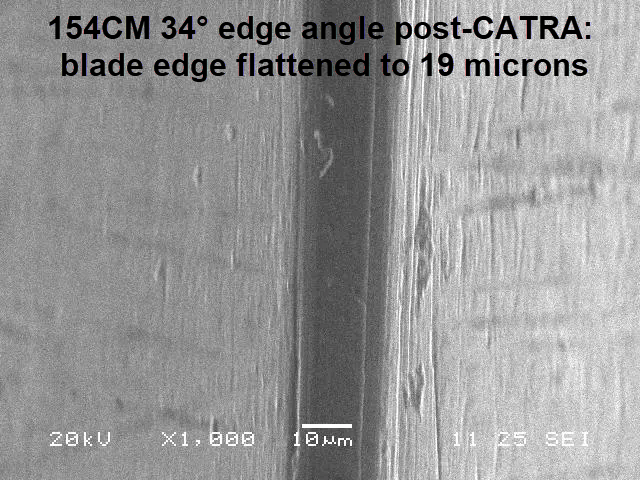

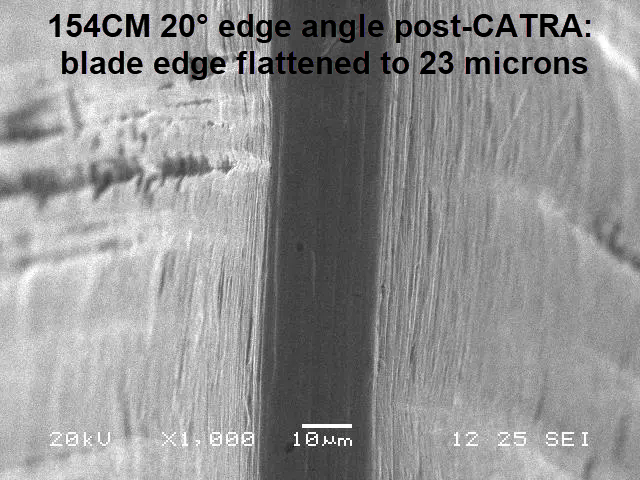

KSN tested the difference edge angle geometry makes in the cutting ability of knife blades using the Cutlery and Allied Trades Research Association (CATRA) edge retention test process, which cuts specially designed cardstock with a specific amount of abrasive embedded for a series of cuts at a constant pressure (I’ll have more details on CATRA testing in the Part 2 post). The Total Card Cut (TCC) results are measured in millimeters. KSN examined the test effects on 154CM blades of the same hardness ground to different edge angles.

After the CATRA tests were performed, he examined the effects of cutting through the abrasive cardstock.

According to the KSN assessment of the edge retention testing results, “Edge angle had by far the strongest effect on edge retention, much stronger than other effects such as PM vs ingot and the finish it was sharpened to.” The article continues, “Some have speculated that lower angle edges start out sharper but a more obtuse edge lasts longer.”

As we can see, the most flattened blade edge angle was the 20° grind. KSN states, “The initial blunting rate is relatively rapid regardless of angle and it then begins to level out. The highest TCC measured was over 1000 mm with an angle of 20°, and this decreased all the way to under 100 mm with 56°.” This is a 10x difference between the most acute vs the most obtuse blade edge angle geometry for the same steel of the same hardness. The KSN article concludes, “So it appears that with a lower angle edge it can wear down to a larger apex and still maintain better cutting ability than a higher angle edge.” It’s clear that despite the 20° edge experiencing a broader flattened edge than the other grinds, the 20° edge remained narrow enough to continue cutting when the less-affected wider grinds could not. This is a very interesting result!

Types of Blade Edges

Of course, not all blade edges are symmetrically ground. In the image below, you can see that many of these edge types are single-bevel grinds. However, these grinds often compensate for overly acute blade edge angles with slightly steeper primary bevel edges.

So, when we talk about blade geometry, we’re ultimately talking about aligning the edge bevel angles to the toughness (resistance to brittleness) property of the steel, which is critically important to the performance of the knife blade.

Heat Treatment Process

The rated hardness of the steel is also a significant factor in the retention of the blade edge. Some blade steels, especially the modern knife blade steels, are engineered to achieve a higher hardness than other steels. Of course, there is also a high positive correlation of a steel’s hardness potential and its price as blade stock. CPM Rex 121, which has a hardness range between 67 to 70.5 HRc, is more than a wee bit costlier than 420, which has a hardness range of 48 to 56 HRc. While I checked for comparative prices of raw blade barstock, I could not find anything for the relatively rare Rex 121. And with the exception of Spyderco, who infrequently uses Rex 121 in a knife release (although as I write this, they are selling their new Sage 5 with a 3” Rex 121 blade and cheap Burnt Orange G10 scales and a bent paperclip pocket clip for $255 on eKnives), almost no one else uses the difficult to machine steel in production knives.

The quality of the knifemaker’s heat treatment can make or break the quality of the finished knife’s blade. When knifemakers buy steel from their suppliers, the steel comes annealed. This means the steel has been heat treated to be in the softest, most malleable state possible, typically between 15 and 25 HRc, to ease the load on the knifemaker’s tools and equipment, improve both machinability and formability, and to ensure the steel does not take on undue stress during the initial work, which could induce the creation of tiny, structural fractures and ruin the final blade’s toughness. Once the blade’s basic design is cut from the steel blank, all holes are drilled, all grooves and slots are milled and the initial, rough grind is applied, the knifemaker is ready to begin the blade steel’s heat treat hardening process.

Initial Heat Treat

Each variety of steel has its own specific set of heat treat recommendations and protocols to follow to attain the optimal balance between hardness and new crystal (called grains in metallurgy) growth along with the formation of carbides (hard compounds formed between carbon and other elemental metals within the steel). The pre-heat-treated, annealed steel’s molecular structure is mostly made from ferrite and some cementite carbides that, comparatively speaking, are not very hard. The non-heat-treated steel will also contain some primary carbides that developed within the steel matrix when it was initially cooled during manufacturing. The basic goal of the knifemaker’s steel heat treat process is to transform the existing ferrite and cementite into much harder crystalline (grain) structures (and sometimes also dissolve the primary carbide cementite into much harder secondary carbide particles) within the steel, then preserve those new microstructures (usually) by a controlled cooling of the steel (in some cases, rapidly doing so).

The knifemaker’s initial hardening treatment heats the milled and shaped steel blade blank, depending on the variety used, to temperatures ranging between 1,400°F to 2,200°F (760°C to 1,204°C, far below the melting temperatures between 2,500 – 2,800°F [1,371 – 1,538°C]) in a controlled environment of a dedicated, vacuum heat treat furnace. The temperature used, which correlates to the formation of specific, beneficial grain structures desired in the type of steel used, it is held there for the recommended length of time. In addition, carbon, which is the key to this process, becomes available in solution within the steel matrix as some of the cementite carbides partially dissolve. After that, the next step is the cooling process.

The cooling process is just as important as the heating process. And depending on the variety of steel used, the cooling can be done in a variety of ways. Some steels do best with a slow air-cool, whereas others maintain the heat-treated new grain structures better by a faster plate-quenching (being pressed between 2 plates of room-temperature metal). However, most modern steels need an even faster quench to maintain those new microstructures, such as immediately submerging the near-white-hot steel into a quenching liquid, typically one of various types of dedicated quenching oil, but in some cases, simply in water. The precise cooling methodology used ensures the grain structures achieved in the high heat treat process do not become undone in a slow cooling, especially with modern steels.

The most important benefit from the high heat treatment is the formation of austenite, a steel microstructure phase that’s super-saturated with dissolved carbon. When most steels are quickly cooled as according to its specific treatment protocol, the austenite will not breakdown as it cools, but instead will actually transform into the very hard microstructure, martensite. Quick cooling prevents the carbon atoms in solution from precipitating out of austenite to rebuild those cementite carbides, enabling the cooled steel to benefit from the hardness of martensite grain structures. Metallurgy is so cool!

So why would you ever do anything but fast cooling? Well, some alloy steels, due to one or more of their alloying elements (especially chromium, molybdenum, manganese, and enhanced with nitrogen), increase hardenability by delaying the formation of less hard steel microstructures pearlite and bainite formation, thereby allowing martensite to form with slower cooling rates.

Effects of Carbides

As you will see below, the type, size, density and distribution of carbides in the steel, created in the blade steel during initial manufacturing and further developed during heat treat, can have a significant impact on the performance of the finished steel. Details on the common types and hardness of carbides found in blade steel are shown in the table below.

| Carbide Type | Composition | Hardness (Vickers) | Hardness (Rockwell c) |

|---|---|---|---|

| Iron (Cementite) | Fe3C | 750 | 60-65 |

| Chromium #1 | Cr23C6 | 1,200 | 68-70 |

| Chromium #2 | Cr7C3 | 1,336 | 70-72 |

| Molybdenum | Mo2C | 1,500 | 75 |

| Chromium Nitride | Cr2N | 1,700 | 78 |

| Chromium Nitride | CrN | 1,800 | 80 |

| Tantalum | TaC | 1,800 | 80 |

| Tungsten | WC | 2,000 | 82-84 |

| Niobium | NbC | 2,300 | 85 |

| Vanadium | VC | 2,400 | 85-90 |

| Titanium | TiC | 3,200 | 90+ |

| Molybdenum/Tungsten | M6C | 1,400-1,500 | 70-75 |

| Vanadium-enriched Cr | CrV7C3 | 1,600-1,700 | 76-78 |

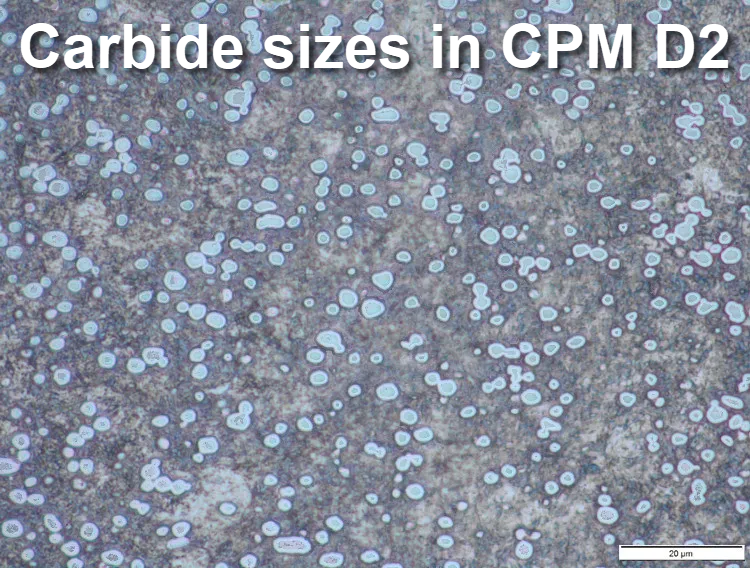

However, the hardness of the various carbides is not the only factor affecting blade steel performance. Size matters (oh doesn’t it, now!).

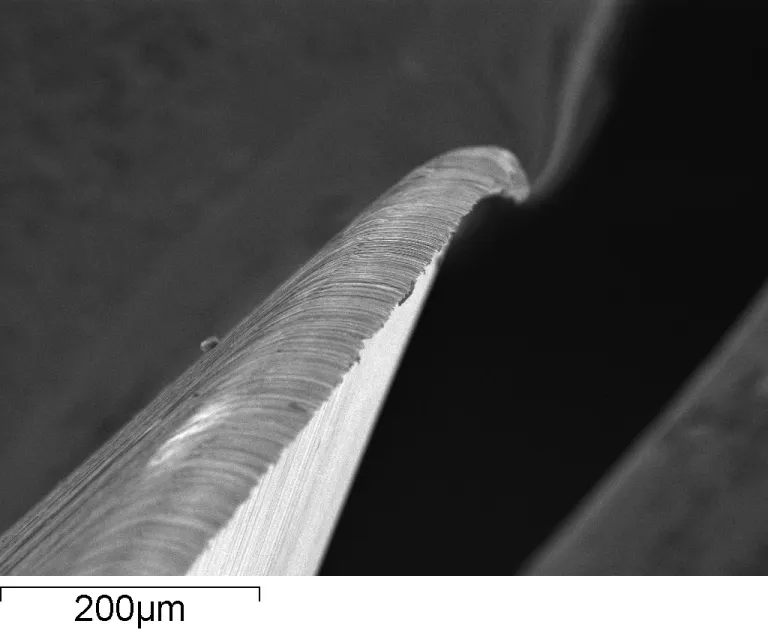

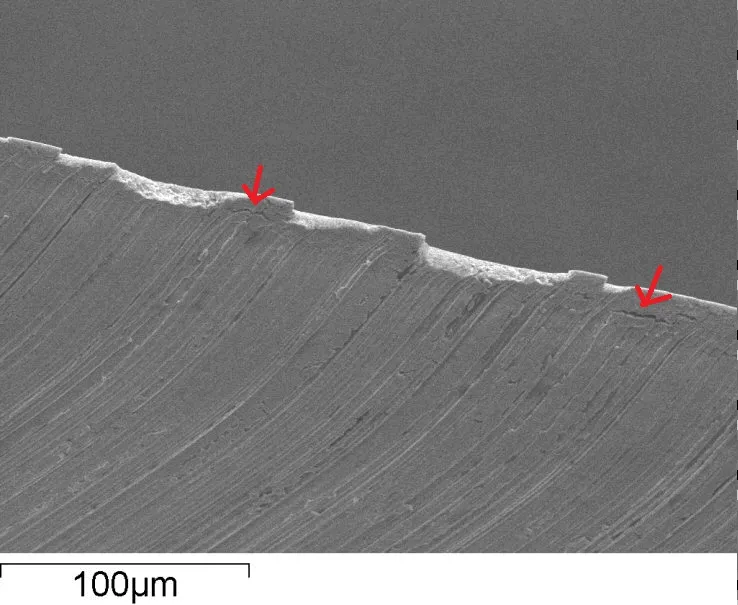

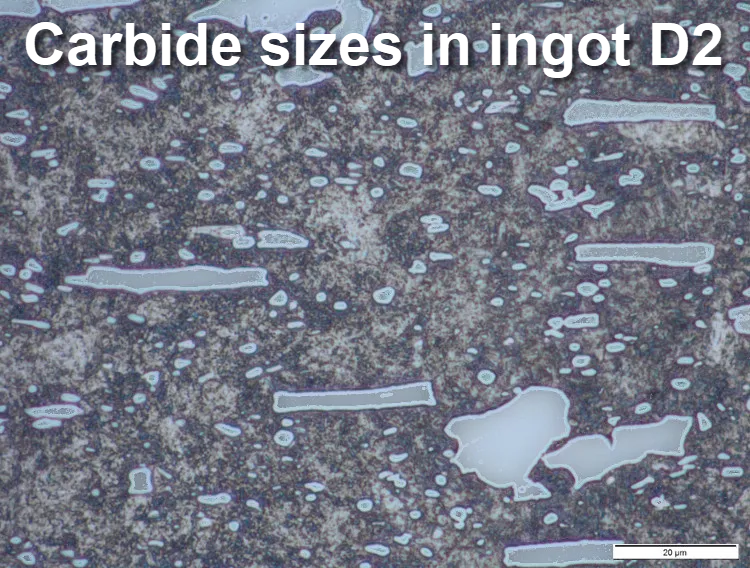

Carbides are far more brittle in addition to being far harder than the steel matrix. As a result, the large boundaries of large carbides in the matrix will form potential fracture lines, where the steel is far more easily fractured.

As you can see in the “third column” of the above image, when there are larger carbides, just a modest side load on the blade edge can overwhelm the toughness strength of the steel matrix, and the amount of blade edge material lost in the fracture can be substantially larger. This is a reflection of brittle (low toughness) steels when the blade edge chips. To help mitigate this problem, steeper blade edge angle grinds can be used to add more material that must be overcome before the fracture occurs.

You should also note in the image above that the density of carbides in the matrix can also be a factor of the toughness rating. Higher carbide density can be a very good thing for blade hardness and edge retention, but because it presents more carbide-matrix boundary lines, it will also be detrimental to toughness. Steel compositions are almost always a compromise between the 3 key properties!

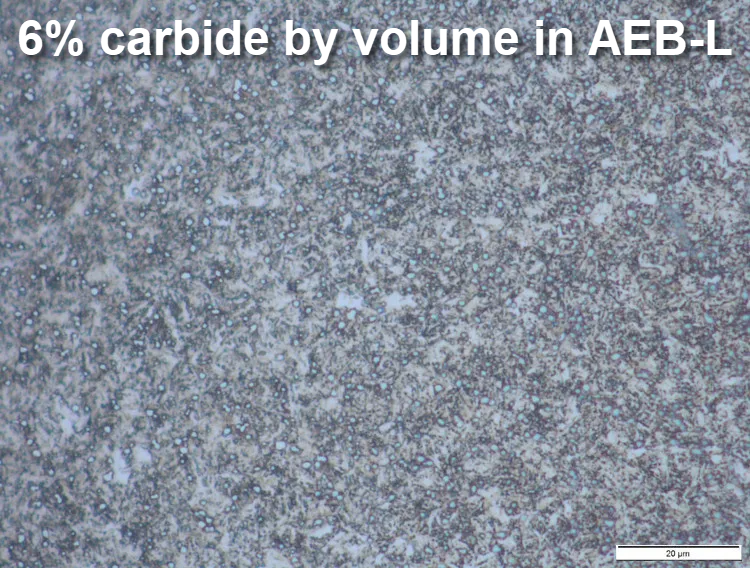

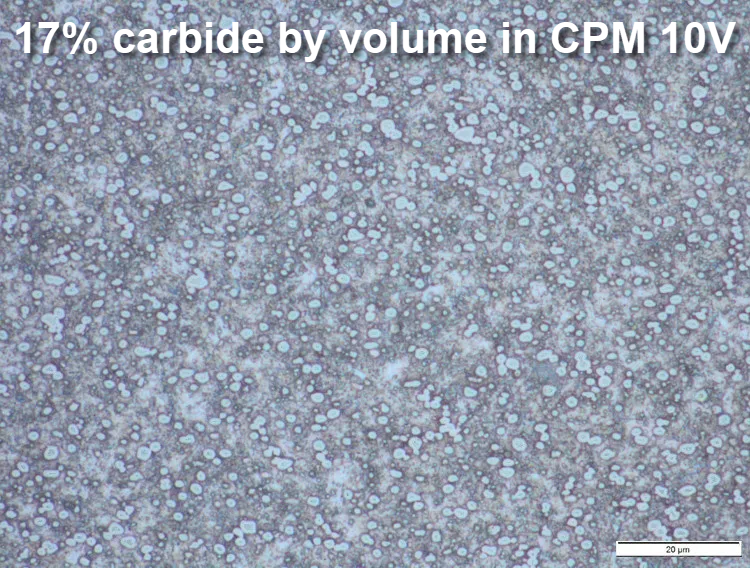

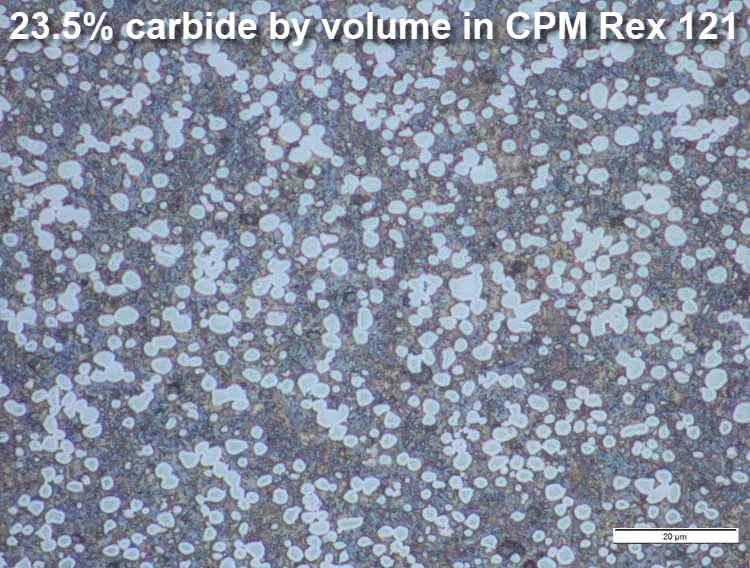

Here are 3 examples of blade steels with varying volumes of carbides, and you can see the differences.

Can you guess which steel of the 3 above will have the lowest toughness? Can you guess which one will have the best edge retention? Yep, CPM Rex 121 in both cases. Due to their carbide volumes, these different steels will progressively get harder and have better edge retention, but they will also have descending levels of toughness.

Differences in Carbides Between Ingot vs. Particle Metallurgy Steels

As mentioned above, the manufacturing process in which the original steel was created can have a significant impact on the steel’s grain microstructures and the type, size, density and distribution of the carbides formed.

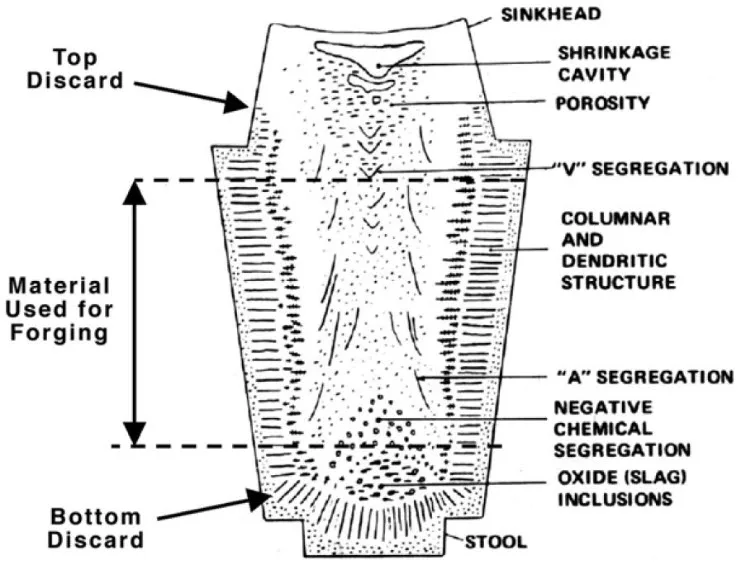

Older steel mill manufacturing technology created conventional ingot steel by pouring molten alloy into large molds that formed slow-cooling ingots. The problem was that the length of time needed for the entire ingot to cool, especially given the uneven cooling of the ingot’s surface versus its interior, allows for the steel alloy elements to segregate out of the uniform matrix, potentially creating very large carbides.

These large carbides induce brittleness in steel because stress cracks typically form and propagate along the boundaries of the large carbides, making the steel more susceptible to fractures or even catastrophic breakage when under lateral stress. At a minimum, such steels are more likely to suffer significant, microscopic chipping along the thin blade edge as well. There are processes that blade manufacturers can do to their ingot steel to somewhat mitigate the elemental segregation, and thus help in a limited way improve the low toughness, but it can’t be fully eliminated in ingot steel.

Because of this inherent problem, steel manufacturers sought to develop a controlled method of reducing the size of carbides when the molten steel is cooled. In 1970, a solution was developed by Crucible Industries, and many of the stainless steels in use today are based on their technology. The new steel manufacturing process, called Crucible Particle Metallurgy (CPM) and similar “powder metallurgy” steels from other manufacturers, is created by passing molten, liquid steel alloy through a high-pressure spray nozzle into a nitrogen-filled chamber. The spray process allows the steel to quickly cool into a uniform powder of tiny, spherical droplets of metallic micro-ingots that do not suffer from elemental segregation of their alloy elements. The resulting steel powder material is then added to sealed containers that are heated under pressure to bond the particles into a homogenous, solid ingots with a uniform, very fine microstructure, ensuring the carbides in the steel are small and evenly distributed throughout the matrix.

The development of particle metallurgy steel manufacturing has completely revolutionized the quality and utility of steel products available today.

Cryo Treatment

To further enhance the hardness of blade steel, some knifemakers employ a cryogenic treatment immediately after the heat treat quench (before the blade has reached room temperature). This involves placing the quenched, warm blade blank into an extremely frigid, controlled-temperature environment, typically cooled by liquid nitrogen or solid CO2 (dry ice) for a specified period of time.

Cryo treatments as an add-on to the overall heat treatment process helps further harden the steel by a number of means, such as converting retained austenite into martensite, reducing some of the stress built up within the steel during the heat treatment process, promoting the transformation and even distribution of smaller carbides, increasing blade ductility (improving toughness), and can even enhance corrosion resistance and edge retention in some steels. Both the amount of time the blade spends in the cryo environment and the lower the temperature used can have a markedly beneficial effect upon some steels, especially in certain tool steels and in stainless steels that have high levels of carbon or alloy elements. The final step of cryo is a slow, gradual rise to room temperature. This is done to stabilize the changes in the steel microstructures, reduce thermal stress, and more. However, many knifemakers, especially those making cheap knives, opt to skip the cryo step due to costs and time (same thing, actually).

Tempering Treatment

Lastly, the final step in the heat treat process is tempering the steel. This is a reintroduction of heat, albeit at lower temperatures than used during the initial heat treat. Tempering blade steel offers a number of significant benefits. One of the ironies is that tempering slightly reduces the hardness of the steel. You might think this counterintuitive result to be negative, but the benefits of tempering definitely outweigh the slight loss of hardness. Tempering relaxes the remaining stress within the grain matrix in the steel. This results in improved steel ductility, reflected as improved toughness (same thing, right?). The relaxation within the steel microstructures also contributes to greater machineability, dimensional stability, and greater edge stability.

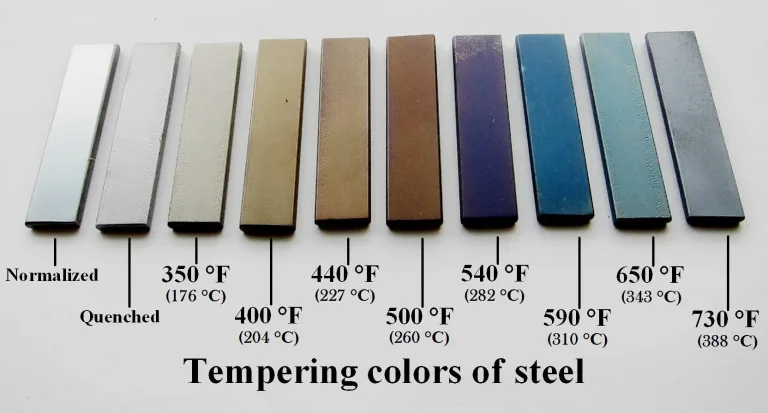

While tempering in a precisely controlled oven is best, the color of tempered steels can be indicative of the temperature used for tempering. Of course, blades are almost never sold with the tempering color still in place!

How the steel is tempered makes a significant difference in the outcomes. Higher tempering temperatures can improve steel toughness, but inversely decreases the final hardness. Tempering temperatures can range from as low as 300°F – 400°F / 149°C – 204°C, commonly used for high carbon tool steels to limit hardness loss (at the expense of gaining toughness), through the medium range of 400°F – 800°F / 204°C – 427°C, typically used for 1095 carbon steels and budget grade stainless steels to find a balance of blade hardness and good stress relief, which improves toughness, to the high end of the tempering range of 800°F – 1200°F / 427°C – 649°C, mostly used on impact-resistant tools and large cutters like machetes rather than pocket knife blades, as these temperatures offer significantly higher toughness, but at an equally significant expense of hardness. Each variety of blade steel has its own tempering protocols to help achieve the blade steel properties desired by the knifemaker. Sometimes one or more of the heat treatment steps are performed multiple times to further promote the benefits that can be achieved from that step in the process.

One thing you may have noticed – these steps take bladesmithing skills, require quality equipment for better controlled processes, and most of all, they take time. And in business, time is money. Many large-scale knifemakers want to keep their costs as low as possible so they can charge less but maintain their profit margins. You want cheap? You’ll get cheap. This is not to say that all cheap knives are garbage and all expensive knives are well-made. Hardly, especially the latter! But to get a well-made blade, you need a skilled bladesmith who understands the metallurgical properties of the steel for which she is forging. That education and experience will minimize warping damage to the steel during the heat treat process, optimize the blade for the properties the steel has to offer as well as achieving the goal of the end product (a machete and a folding knife have vastly different performance requirements from their steel blades). But that expertise has a price. So do the raw blade materials, as do the handle scale materials, the knife’s milling and machining requirements, the blade finishing and final sharpening, and more. It adds up!

Other Performance (and Value) Factors

Remember how just a couple of years ago, many knife retailers used to put the knife’s HRc hardness rating on their website’s product page? Well, that seems to have stopped over the past year or so. As customers get more savvy to the desired properties of their prospective knives, knifemakers and their retailers are loathe to provide results that are less than optimum, so that data has largely disappeared, at least from knives whose blade steel hardness is inferior.

But that said, also remember when digital cameras used to be judged solely by megapixels or cars by horsepower? Hardness is an important performance factor, but it is definitely not the only factor of knife quality and value. A hard blade that chips and easily breaks (low toughness) is near useless. A knife that easily rusts over (corrosion resistance) is a lousy knife for those who live and work around water, moisture and humidity. A knife whose blade is so soft that it’s impossible to keep sharp (edge retention) of is so hard that it’s near impossible to sharpen (ease of sharpening) is not valuable over the long run!

Now that I have bored all of you to tears (yes, I heard the collective moans and sighs of resignation, along with a few wailing sobs of profound regret, from each one of you), let’s take a look at budget blade steels in the Decent category (Part 2), then in both the Mediocre, and the Junk categories (Part 3) of budget blade steels.

Knife Karen Nitpicks

This has been a long, detailed exploration of commonly available budget steels from online retailers as well as the many factors that affect blade performance. Are you ready to see how these factors affect the various categories of budget blade steels in Part 2 and Part 3? No? Well, then I will need to speak to your manager. Right now!

- First off, well over half (23 of 40) of the online pocketknife retailers I visited had websites so crappy that I could not use them in this analysis. The problems I encountered are the same problems potential pocketknife shopping customers will find: the website search was terrible and could not be filtered for factors important to shoppers, such as price, blade materials, and much more. Hey retailers, if you are wondering why the big sites are eating your lunch (and dinner) on knife sales, it’s because your website sucks. Wake up, invest a little money in your site, and watch the money roll in. Why don’t you know that already? Who is your manager?

- Many online knife retailers include garbage data in their knife listings. Some ridiculous blade materials listings include such indeterminate steel types as ”carbon steel”, “surgical steel”, “400 steel”, “Damascus” (without listing the component steels), even “unknown” (!), but by far, the worst (and most common) is just “stainless”. Incredibly, some of the biggest online retailers are the worst offenders in this space, and shockingly large percentages of their entire inventories are listed simply as generic stainless. How useless! I’m specifically looking at you, Chicago Knife Works (27%), BladeHQ (14%), Smoky Mountain Knife Works (14%), Heinnie Haynes (11%), and DLT Trading (9%). No other online retailers had anything higher than 4% of their inventory listed this way, and most were far lower than that. If your suppliers are so bad that you don’t get any blade steel info from them, then demand changes. But if you do have the specific blade steel data and you just refuse to do the work to show it, then shame on you! Hire a few people who need a job to fix this ASAP!

Verdict

The number of budget, folding pocket knives available for sale these days is amazing. As I am keenly interested in the blade steel metallurgy aspect of the knife world, I had this idea that I’d check out which steels are out there in the budget category (which I define as < $100 – inflation, you know!). I thought I’d go online, check out the big e-commerce knife retailers, see what’s most popular, and do a little comparative analysis on my findings. 2.5 months later, I am finally done. I did have a lot of other things going on, such as my full-time job (I work at a sandpaper factory and recently got promoted to Assistant Sifter!). I also had to upgrade the website to use some new tools (I hope you like tables!). But mostly, I had to do a ton of research, data gathering, analysis, and then see where all of that led to.

And what that process did lead to was a comprehensive list of 185 blade materials found in budget folding knives! I figured out which steels were the most commonly used. After that, I ranked those popular steels into 3 category levels of “quality”, which I euphemistically call, in descending order of quality, The Decent, The Mediocre, and The Junk. I then associated lesser-sold steels that are either very closely related or identical to the most common steels, but sold under different names, leading to the creation of “steel families” that represented the vast majority of the blade steels found in my budget blade online retail inventory. That was the easy part! After that, I had to document which features and qualities made the steels I ranked fall into their respective categories. You see, I may be a crank (you think?), but my work is well-researched, documented, and the arguments well-supported.

So what did I learn? Where do I begin? I learned that:

- There are a large number of online retailers of folding pocketknives.

- The various sizes of retail inventory offerings were huge! Some retailers had vast inventories of different knife models, while others were surprisingly unimpressive.

- Over half of the online retailers have truly terrible websites and/or have near useless site search and filtering, so bad that I was unable to gather information from them. If I was unable to search for knives with a specific blade steel or knives under a specified price, then neither can prospective customers, who will take their business elsewhere.

- Many retailers that do offer blade material filtering have very poorly categorized inventory. In one case, almost 27% of the knives for sale simply identified the knives had “stainless steel” blades. That’s not even a variety of steel but instead a broad category (which spans from 2Cr13 to MagnaCut!). I name names and call out those failures.

I then go into the various blade steel performance factors, , such as Toughness, Edge Retention, and Corrosion Resistance, which I used in my analysis. I define these factors, how they are calculated (when they are calculated!), and describe why some steels just are naturally poor performers. For fun, I also include the individual steels’ elemental composition, and how to identify expected steel performance factor characteristics from the amount of specific elements used in a given steel. And for kicks and giggles, for each steel covered, I included the rated range of Rockwell Hardness c ratings and their Ease of Sharpening ratings (which are subjective, but people seem to want these opinions). And I do all of this by showing where I got my various rankings data. For the most part, I lean heavily on the authoritative data found on KnifeSteelNerds.com, but I also include opinions from several other popular knife websites.

So what’s the verdict? You can get some good performing blade steels on pocketknives that cost less than $100. That’s great to know. But you can also get some real dog crap blades in the same category. Of course, there’s more than just steel type when assessing whether a pocketknife is a good value for the price. Factors such as the handle and accessory materials, design elements, ergonomics, blade shape, lock mechanisms, opening methods, machining tolerances, pivot action, and more. But, if you buy a knife that has all high-end levels in all of that, but it also has a crap blade steel that is so low on toughness that it’s likely to chip, crack or break, so poor on edge retention that it dulls immediately upon use, and/or the steel has such poor corrosion resistance that it’ll rust due to nothing more than normal humidity levels, then you have to question if that knife is worth it.

This post is Part 1 of 3. Part 2 is a review of the blade steels in the Decent category, and why they are in that category. Part 3 is a breakdown of the Mediocre, and for more fun, the Junk categories of blade steels. I include the same amount of technical documentation, and, as usual for me, The Knife Karen, you’ll find more than a fair share of snarky comments throughout. If you like what you see, come back for more. I have a lot of interesting, new material planned! Enjoy! ![]()