What would you do if you had a new C-note, a genuine Benjamin burning a hole in your pocket, and you wanted to buy a new budget pocketknife? Would you know which to pick? Do you know what blade steel to get?

In Part 1 of this series, I discussed the methodology I used to collect a large inventory of Budget-level (all knives under $100) pocketknife blade steels from 17 online pocketknife retailers (there originally were 40, but most of the 23 others had uselessly crappy website search filters, and a small few had pathetically small budget pocketknife inventory levels). We also looked at the important blade steel performance factors that should be considered before buying your next budget knife. Now let’s apply that information to the actual budget blade steels I collected.

I gathered the most common of these budget blade steels from the inventory can assigned them into 3 basic categories:

- The Decent,

- The Mediocre, and

- The Junk. Yep, I said it.

I then looked at the most common steels per category, and then gathered identical (and very similarly related) groups of blade steel “families” around these most common steels. Now I’m ready to do some real steel spiel.

In this article, Part 2 of the 2024 Budget Blade Round-Up series, I take a detailed look at the best (yeah, right – the best!) of the budget blade steels I found: The Decent. I compare these “Decent” steels by the 3 key steel properties, as rated by TOP INTERNET SOURCES (well, KnifeSteelNerds.com, and a few other blogs and online articles, just for comparison’s sake), which are important traits for pocketknife steel: Toughness, Edge Retention, and Corrosion Resistance. I further analyze these “Decent” steels for ratings on Rockwell C hardness, Ease of Sharpening, and Elemental Composition. And for funsies, I gathered the collected ratings from the authoritative KSN data.

So, are you ready to do a nuclear nerd-out on pocketknife blade steel? Yeah, I’m not either, but I’m moving forward, anyway. At a minimum, after reading this entire post, as well as the preceding one and the next one, you’ll get a better idea of what to be looking for (and what to avoid) in a budget folding knife blade.

TL;DR

If you don’t have the funds right now for an exquisite, high-end pocketknife, then there’s the budget category of knives. Sadly, I still don’t have the cash on hand to pick up a new Polish Herman knife (hi, Mr. Bartosz Herman, jeśli kiedykolwiek będziesz chciał bardzo dokładnej recenzji online jednego z Twoich wspaniałych dzieł sztuki noża, który zajmie pierwsze miejsce w Google, napisz do mnie na Instagramie! Porozmawiajmy!). But if you do go down the road of shopping for a budget pocketknife, at least choose one whose blade steel is in the “Decent” category. You’ll get

budget working knife to use (which rules out gas station knives), learning about the best budget blade options will help you get the most for your money.

Pros

- Quality steel can offer higher levels of the 3 desired properties of blade steels, although the levels of these properties can often be at odds with one another. Usually, you can only get, at most, a combination of 2 out of those 3 desired properties in reasonable levels for a given steel. You will need to prioritize which property is most important to you and go from there:

- Toughness. Resistance to fracturing or chipping; brittleness

- Edge Retention. Resistance to wear from abrasion; how long the edge stayed sharp

- Corrosion Resistance. Resistance to damage from oxidation and other factors; rust.

Note: You can learn more about knife steel properties in the section titled, Sidebar: 3 Key Properties of Knife Steel – Pick 2 from my earlier post about the Mikov Kostka funny folder knife.

- Ease of sharpening is also an important feature, but less so in budget knife steel, as none of these are likely to be overly hardened (or in some cases, not very hardenable), so they all should be pretty easily sharpened with less expensive sharpening stones.

Cons

- Out of the 185 budget blade materials I found in my collected online pocketknife retailer inventory, there are very few that rate as Decent.

Blade Steels Compared

While blade geometry and proper heat treatments are important to pocketknife performance, I know what boys want. Boys want my MagnaCut, don’t you? Well, settle down and listen up. Finding properly heat-treated MagnaCut on a budget knife is about as rare as finding a platypus beak in a can of Bean with Bacon condensed soup. Yeah, it theoretically could happen, but don’t hold your breath (even though platypuses have to). Technically, there were 77 listings for MagnaCut steel in my inventory survey of sub-$100 budget blade knives, so when writing my above comments in this paragraph, I went back to review those specific examples, and as I suspected, the websites that supposedly had this rare combination either listed non-priced, “Coming Soon” knives or had such poor site search that the filters just did not work at all. No platypus beak soup for you!

So, let’s reset our expectations and look at what types of blade materials really are available in the budget territory. In this Part 2 post, I’ll focus on the Decent category of budget pocketknife blade steels. And for a bit of weird, cringy jocularity, I will be introducing some of my cute Blade Steel Property Friends along the way as well. You know, just to put some semblance of fun in what is a rather dry subject, right? Whatever.

In this series of budget blade steel reviews, I will lean heavily on the authoritative research of Dr. Larrin Thomas, the knife industry’s leading metallurgist and the author of several books, including Knife Engineering: Steel, Heat Treating, and Geometry, The Story of Knife Steel: Innovators Behind Modern Damascus and Super Steels, and the founder of the popular blog, KnifeSteelNerds.com (KSN). However, I will also be including related content from other online resources that are popularly referenced in the community. But for a real treat, take a look at the KSN article in which Larrin ranks the steel ranking articles on the Internet! What a hoot!

Organization of the Results

I reviewed the many steel varieties captured in my survey of budget-priced knives and found several reasonably good quality types of steel that were highly represented in the survey results. Additionally, each of those major steel varieties have very similar (if not identical) steel compositions that offer similar qualities and performance. As part of the organization of the data, I selected the representative steel type with the largest representation within its category and listed them in descending order by the aggregate inventory. I followed this same process within each family sub-group. Yes, I am a details nerd. Just note that the order of the steels within a category is not a descending ranking of quality, but instead a descending order of quantity of my inventory of the online vendors. Each member of a family group is more or less equal, as are the members of the categories (the Decent, The Mediocre, and the Junk). Moving on…

The Decent: Higher-End Budget Blade Steels

For the most part, the steels you will typically find in the budget category are not premium. Heck, a lot of them are pretty crappy, little more than low-end-to-literal-crap steel—very soft, poorly (or completely non-) heat-treated, with poor toughness, poor edge retention, poor rust resistance, and even difficult to keep sharpened (removing the sharpening burr from soft steels can be extremely difficult; it simply flops over from side-to-side and never breaks away, so the edge is only “sharp” for a few, if only one, cut).

That said, there are respectable steels available in the budget category that can serve you well for basic cutting. You’ll want to learn how to sharpen and strop the blade because it will need periodic touch-ups. You’ll also want to avoid using your knife blade as a screwdriver, a chisel, a pry bar, and anything else other than a cutting instrument, as you could chip, bend or break the blade (and if you try, you can achieve all three!). But if you take care of your budget knife made from these steels, you’ll have a good experience. Let’s review the steels to specifically look for when buying your next budget knife.

With the exception of the high alloy tool steel, D2, and its family of similarly composed steels, all the rest of the steels in this higher end category are stainless. All but 2 of these higher end steels are ingot-formed, where molten steel is poured into a large mold and allowed to cool. Those other 2, CPM D2 and CPM 154, are particle metallurgy steels, where molten steel is sprayed out of a nozzle into a pure nitrogen-filled chamber (ensuring the steel is not exposed to oxygen!) and the steel cools into a powder.

The key benefit of particle-based steels is the formation of much finer carbides (the very hard bits in the steel matrix that gives it its edge retention). Since ingot steels cool unevenly (the outside cools faster than the interior), the carbides formed are unequally distributed and can be much larger. Sounds good, right? Bigger hard bits!

But that’s not necessarily so. Imagine having pebbles embedded in red clay bricks. If you give that brick a hard knock, you’ll see the brick will crack apart more easily, and it’ll do so along the surfaces of the pebbles inside near the impact, because the cracks in the brick formed around the borders of the pebbles with only short lines needed to reach the next pebble, making the brick more brittle. If you compared that pebble-laden brick to a similar, solid red brick made from fine clay, the more uniform, fine structure of the clay will give the brick an increased resistance to cracking under the same impact. Blade steels work the same way. I discuss the differences between ingot and particle steels in more detail in another post – check it out!

You’ll also note that many of these Decent steels are old. As old as the hills. Even older as me! Generally speaking, these aren’t the latest and greatest steels available, and this trend only gets worse as we go down the list of category grades. Hang on to your hat!

The Decent: Introduction

| Blade Steel Family Types | Quantities =< $99 | Aggregate Total | Type | Class | Process | Manufacturer | Invented | Country |

|---|---|---|---|---|---|---|---|---|

| AISI D2 | 6,501 | 6,751 | High Alloy Steel | Tool | Ingot | various | 1918 | US |

| • Bohler K110 | 242 | High Alloy Steel | Tool | Ingot | Bohler-Uddeholm | Late 1990s | AT | |

| • Crucible CPM D2 | 8 | High Alloy Steel | Tool | Particle Metallurgy | Crucible | 2007 | US | |

| Alleima (Sandvik) 14C28N | 2,838 | 3,842 | Stainless Steel | Ingot | Alleima (Sandvik) | 2008 | SE | |

| • NJSB Nitro-V | 998 | Stainless Steel | Ingot | New Jersey Steel Baron | 2017 | US | ||

| • Alleima (Sandvik) 13C26 | 4 | Stainless Steel | Razor | Ingot | Alleima (Sandvik) | 1975 | SE | |

| • Bohler AEB-L | 2 | Stainless Steel | Razor | Ingot | Bohler-Uddeholm | 1960s | SE | |

| Takefu VG 10 | 1,138 | 1,262 | Stainless Steel | High carbon | Ingot | Takefu | 1959 | JP |

| • 10Cr15CoMoV | 124 | Stainless Steel | High carbon | Ingot | Ahonest Changjiang | Mid 2010s | CN | |

| Crucible 154CM | 1,211 | 1,256 | Stainless Steel | High carbon | Ingot | Crucible | 1970 | US |

| • Crucible CPM 154 | 33 | Stainless Steel | High carbon | Particle Metallurgy | Hitachi | 2005 | JP | |

| • Hitachi ATS-34 | 12 | Stainless Steel | High carbon | Ingot | Crucible | Late 1970s | US | |

| Bohler N690 | 600 | 703 | Stainless Steel | High carbon | Ingot | Bohler-Uddeholm | Late 1980s | SE |

| • Bohler N690Co | 101 | Stainless Steel | High carbon | Ingot | Bohler-Uddeholm | Late 1980s | AT | |

| • Bohler N695 | 2 | Stainless Steel | High carbon | Ingot | Bohler-Uddeholm | Late 2000s | AT |

Toughness: The Decent

Let’s look at the toughness, aka the resistance to fracture, of the Decent steels. In this (and the coming sections), I discuss the key properties by which the performance of knife blade steels is assessed. Keep in mind that, in virtually all cases, the combination of the 3 key properties of blade steel – toughness, edge retention, and corrosion resistance – are a compromise, in which you may get good levels of 2 but the 3rd will be significantly lower, and sometimes, in low-grade steel, you may only get 1 property with a good result!

Most online articles use a scale of 0 through 10 to rank knife steels (although the ranking scores used by Blade Reviews are on a scale of 1-5, so to put them in line with all the other rankings, I doubled their numbers). Heck, KSN even published its own steel rankings content, as this is the shorthand info most people search for online, even if it is less precise. However, the rest of the KSN site includes the much deeper analyses that backs up that post. The simple KSN rankings are based on Larrin’s own specific research and testing results.

Measuring Toughness

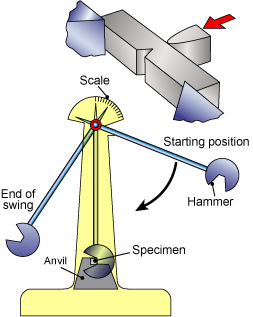

The toughness property of steel is measured by running a Charpy V-Notch Impact test.

The test measures the amount of energy a notched sample of steel can absorb and resist deformation before fracturing, which is calculated as foot-pounds occurring at a specific Rockwell C hardness rating.

The image above shows Charpy-tested steel samples, and at the fracture plane, not only do we see the size and density of carbides, but the degree of steel deformation (indicating ductility vs. brittleness), is clearly visible.

Charpy V-Notch Impact Test Ratings Scale

As discussed earlier, toughness is measured via the Charpy Impact test, which results in a rating of foot-pounds at a specific HRc rating (or at times, the range of ft-lbs. within a range of HRc hardness ratings). Note that there is typically a negative correlation between toughness and hardness – the harder a steel is made, the more brittle (less resistant to fracture) it becomes.

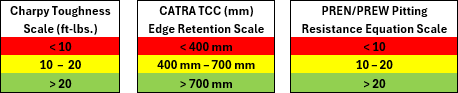

To get the simple 0 to 10 score, there are thresholds for ft-lbs. measurements. The thresholds themselves are not standardized, and comparing Charpy ft-lbs. scores is always better than generic rankings. Unfortunately, that data isn’t always readily available, so most bloggers instead just give recycled opinions as ratings. I did a bit of research into such ft-lbs. threshold scales and compared them to the KSN Charpy data along with the KSN Toughness rankings. For the most part, the following scale seems to be reasonable for establishing a shorthand color ranking:

| Charpy Toughness Scale |

|---|

| < 10 ft-lbs. |

| 10 – 20 ft-lbs. |

| > 20 ft-lbs. |

This isn’t a perfect interpretation, but it’s pretty good, and I used the scale colors to rank the ft-lbs. listings from KSN.

Toughness Table for Decent Budget Steel

Please note that not all the budget steels I found in my assessment have been evaluated by all online reviewers (or in some cases, by any), so in those cases, the spaces with no data are left blank.

The Decent: Toughness

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft- lbs. @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI D2 | 3.5 | 5-3 @ 58.75-63.4 | 4 | 7 | 6 | 5.5 | 4 |

| • Bohler K110 | |||||||

| • Crucible CPM D2 | 5.5 | 11.75 @ 62.5 | 4 | 5.5 | 4 | ||

| Alleima (Sandvik) 14C28N | 9 | 30 @ 60.75 | 9 | 6 | 7 | 9 | |

| • NJSB Nitro-V | 7.5 | 22-9 @ 61.25-63.6 | |||||

| • Alleima (Sandvik) 13C26 | 9 | 37.5-12 @ 60-64 | 6.75 | 8 | |||

| • Bohler AEB-L | 9 | 37.5-12 @ 60-64 | 10 | 6 | 10 | ||

| Takefu VG 10 | 4 | 5 @ 61 | 4 | 6 | 4 | 4 | |

| • 10Cr15CoMoV | |||||||

| Crucible 154CM | 3.5 | 5 @ 60.1 | 4 | 7 | 4 | 4 | |

| • Crucible CPM 154 | 5 | 10-6 @ 60-64.1 | 5 | 7 | 4 | 5 | |

| • Hitachi ATS-34 | 4 | 4 | |||||

| Bohler N690 | 3.5 | 4 @ 62.5 | 4 | 7 | 6 | 4 | |

| • Bohler N690Co | |||||||

| • Bohler N695 |

The toughness ratings for the budget steels are all over the place here compared to the coming categories, so these ratings necessitated that I bring out my Toughness friends, Biff the Tough Blade.

Some are quite good, extraordinary even. The high scores mean those blades will resist chipping and breaking, especially 14C28N and its related family of steels.

On the other hand, a few others were disappointingly low, especially D2, 154CM, N690 and VG 10. This means these blades are much more brittle and will only serve you pretty well if you don’t abuse them by doing anything other than basic cutting. Otherwise, the blade will chip, the tip may break off, and other such results of stressing a brittle blade. Thus we also meet Chip the Brittle Blade. He’s not too proud to be here.

Notice the toughness differences between the 2 particle metallurgy steels, CPM D2 and CPM 154, and their ingot versions, D2 and 154CM. In both cases, the particle steel variants have higher toughness scores, with ft-lbs. scores being doubled at the same HRc. This is a perfect demonstration of how the much smaller carbides formed in particle steels compared to the potentially much larger carbides formed as a result of uneven initial cooling of the molten ingot steel. As mentioned earlier, the boundaries of those larger carbides form the lines in the steel matrix along which stress cracks form and run, making the steel more brittle.

If you see only this and immediately decide that the blade steels in the 14C28N family are what you need, I suggest you continue to read on. As this analysis progresses, you’ll see that the steels with good toughness scores often have far less impressive ratings with other properties. Ultimately, you choose the compromise of which combination of good properties vs. low you need for the way you will use your knife.

Edge Retention: The Decent

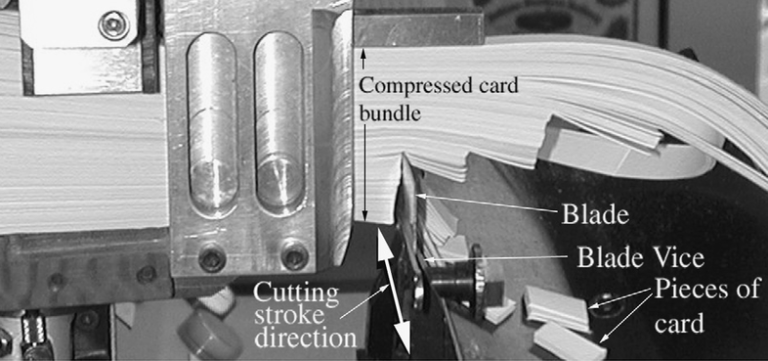

Here we examine the property of edge retention, aka resistance to wear from abrasion. Again, most blade edge retention articles use a 0-10 scale (excepting those rebellious folks at Blade Reviews!). And again, KSN goes into deeper detail, basing their rankings on the results of a Cutlery and Allied Trades Research Association (CATRA) edge retention testing machine doing a Total Card Cut (TCC) test, as measured in millimeters.

CATRA TCC (mm) Test

The CATRA testing machine works by fixing the cutting blade vertically (blade edge up) of the knife to be tested in the machine. The knife’s blade is moved back and forth for 60 strokes as a stack of 1” wide CATRA test card stock embedded with 5% silica (sand) is lowered at a specific angle upon the blade edge. The machine ensures that there is a consistent cutting length, angle and speed, as well as a cutting load of 50g applied. The TCC (mm) measurement is based on the amount of test paper cut. The more paper cut, the higher the CATRA edge retention score. CATRA testing results should always be noted with the tested steel’s Hardness Rockwell C score, as the steel hardness will affect the cutting performance. In the real world, in addition to the hardness, blade edge geometry (the edge angle and the bevel thickness behind the edge) as well as the density, distribution, size and types of carbides in the steel (as a result of the heat treat process) will affect CATRA ratings, which means the ratings for the same blade steel may differ between knives.

Only when the tested blade steels have all these factors equalized can you get fair steel comparison scores. KSN has a nice article comparing the particle steel CPM 154 and the same ingot version, 154CM, describing the CATRA testing process and how the carbide formation differences between these types of steel affects edge retention.

To derive a ranking score, there are thresholds for TCC mm measurements. As above, the ranking thresholds are not standardized, so comparing actual CATRA TCC scores is always better than generic rankings. Also as above, I compared threshold scales and the KSN CATRA data rankings. As a result, I created what appears to be a reasonable colored scale for edge retention ranking:

| CATRA TCC Edge Retention Scale |

|---|

| < 400 mm |

| 400 mm – 700 mm |

| > 700 mm |

Edge Retention Table for Decent Budget Steel

The following are the data I collected for the decent budget knife blade steels and their edge retention. And as above, when data is not available from a given website for a given blade steel, the cells are left blank.

The Decent: Edge Retention

| Blade Steel Family Types | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI D2 | 5 | 485-500 @ 59.1-60.5 | 5 | 6 | 4 | 7.5 | 5 |

| • Bohler K110 | |||||||

| • Crucible CPM D2 | 5 | Similar to D2 | 5 | 7.5 | 5 | ||

| Alleima (Sandvik) 14C28N | 3 | 420 @ 62 | 3 | 3 | 3.5 | 3 | |

| • NJSB Nitro-V | 3 | 360 @ 60.5 | |||||

| • Alleima (Sandvik) 13C26 | 358-445 @ 61-64.5 | 3 | 3 | ||||

| • Bohler AEB-L | 3 | 358-445 @ 61-64.5 | 3 | 4 | 3 | ||

| Takefu VG 10 | 4.5 | 477 @ 61.5 | 5 | 6 | 6 | 5 | |

| • 10Cr15CoMoV | |||||||

| Crucible 154CM | 4.5 | 495 @ 61 | 5 | 7 | 6 | 5 | |

| • Crucible CPM 154 | 4.5 | 492 @ 61 | 5 | 8 | 6 | 5 | |

| • Hitachi ATS-34 | 6 | 6 | |||||

| Bohler N690 | 4.5 | 5 | 7 | 3 | 5 | ||

| • Bohler N690Co | |||||||

| • Bohler N695 |

It’s noteworthy that none of the Decent budget steels rank in the green range of edge retention. None. Welcome to budget steel world. And in fact, the best of these Decent steels are down deep in the lower half of the yellow range, while the best of the Decent steels for toughness, the 14C28N family, have the absolute lowest scores of all here. And with that, I introduce Cullen the Dull Blade. He’s not happy to be included here.

All in all, not so impressive ratings. It only gets worse from here.

There are 2 cells in the table above that were color-coded but didn’t have CATRA scores. I searched the KSN website for the details, which is where I got the rating, but the exact CATRA scores for CPM D2 and N690 were elusive. However, knowing that KSN bases their ranking score on this data, I colored the test cells appropriate for the ratings.

You might be inclined to believe that the harder the steel, the better the edge retention, and in truth, there is a degree of direct causation effect here. But this isn’t necessarily always true, and hardness is certainly not the only factor for edge retention. Edge retention goes well beyond steel hardness, and factors such as the types, size, density and distribution of various carbides in the steel will make a profound difference in how well the blade will hold its edge.

As stated above, the edge retention scores are generically relevant to steels that are heat treated the same way and brought to the same hardness. Of course, edge geometry and carbide differentiations will significantly affect CATRA scores. So, if you want to calculate a predictive edge retention score for your prospective next knife, simply plug the knife blade’s specific data variables into this basic equation:

TCC (mm) = -157 + 15.8*Hardness(Rc) – 17.8*EdgeAngle(°) + 11.2*CrC(%) + 14.6*CrVC(%) + 26.2*MC(%) + 9.5*M6C(%) + 20.9*MN(%) + 19.4*CrN(%)

To help you out, note that this formula refers to CrC (Cr7C3 or Cr23C6 chromium carbides), CrVC (M7C3 where M can be either Cr or V), MC (either vanadium carbides, VC, or niobium carbides, NbC), M6C (Molybdenum/Tungsten carbides), MN (either vanadium nitrides, VN, or niobium nitrides, NbN), and CrN (chromium nitrides). For just a bit more context, check out the KSN article Which Steel Has the Best Edge Retention? Part 2.

It’s easy, right? As simple as mincemeat pie. Have fun!

Corrosion Resistance: The Decent

This section refers to a steel’s ability to resist degradation by oxidation and other external factors. Specifically, I mean rust! The designation of blades as stainless steel or not is not as binary as it may seem. Stainlessness is a spectrum. There is a threshold at which blade steels are declared to be stainless, but some are not as stainless as others, and some non-stainless steels are very close to the bottom threshold of stainlessness.

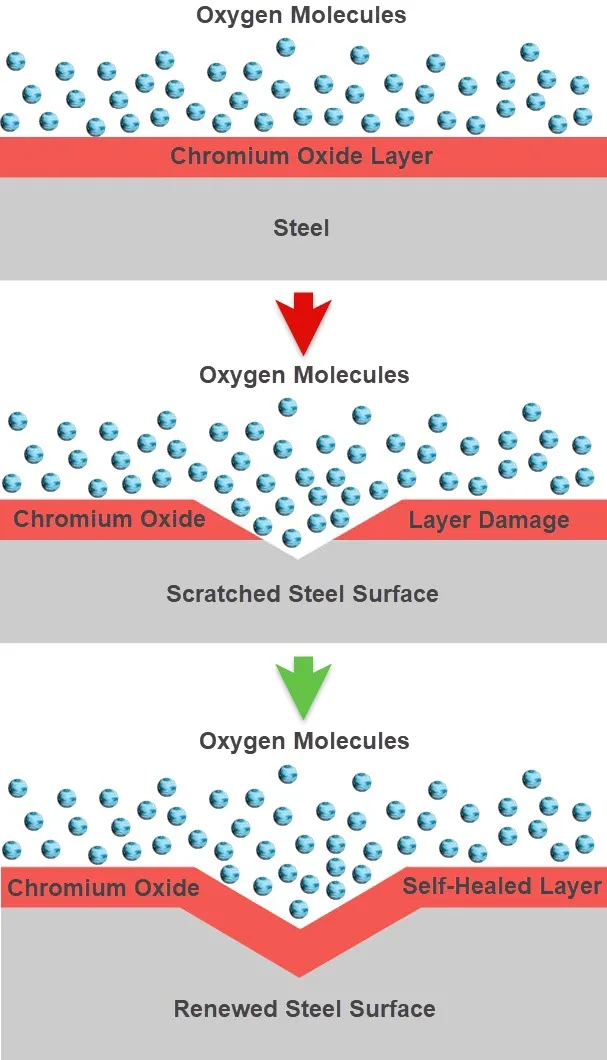

Chromium is the key. When enough Cr is in the steel composition, it reacts with oxygen atoms to form a microscopic, “passive” layer of chromium oxide (Cr2O3) on the steel’s exposed surface, which blocks the steel’s interaction with corrosion-inducing oxygen.

Even when scratched, stainless steel’s Cr2O3 outer layer is self-healing and is re-established in the presence of oxygen.

Stainlessness is typically defined by the amount of chromium in the steel. While there is some debate on the exact measurement at the threshold, the threshold for stainlessness is commonly defined as having more than ~10.5% chromium AND less than 1.2% carbon. A high amount of chromium is needed because Cr tends to precipitate out of molten steel into large, relatively strong chromium carbides. Steel manufactures must add enough Cr to ensure enough remained in the non-carbide steel matrix so it could form Cr2O3 on the steel’s surface. The appearance of hard chromium carbides is good for edge retention, but high levels of Cr also make steel more brittle.

But even the Cr baseline level of 10.5% is not always clear. Since chromium carbides require carbon to form, this explains why there is a cap on the maximum level of carbon. The more carbon available, the more it bonds with chromium to become tied up in carbides, and the less Cr that’s available in the matrix for achieving stainlessness. For example, D2 can have up to 12% chromium. However, D2 also has between 1.5 and 1.6% carbon, resulting in not enough Cr in the matrix for stainlessness. On the other hand, CPM MagnaCut has only 10.7% Cr, but with only 1.15% C, the Cr available in solution to the matrix makes it one of the most stainless varieties of steel available. This is the way metallurgist Larrin Thomas, author of KSN and inventor of MagnaCut, designed it to be, which allows the level of Cr to be minimized and yet maintain excellent stainless properties. This lower level of Cr also benefits the steel by limiting Cr’s effect of lowering toughness. On top of everything, the edge retention of MagnaCut is not reliant on the medium-hard chromium carbides, but instead on much harder vanadium and niobium carbides, which optimize its edge retention. As a result, MagnaCut has probably the best overall, positive balance of all 3 steel properties of any current blade steel. But there’s no MagnaCut in this list. It’s not a budget steel.

PREN / PREW Equation

Like we’ve seen above, the KSN ranking scores are derived from equations based on data about the steels. KSN originally started by using the Pitting Resistance Equivalent Number (PREN) equation, which predicts the level of corrosion resistance by calculating values based on the relative amounts of chromium, molybdenum, tungsten, and nitrogen, and generated a ranking level list. The formula looked like this:

PREN = %Cr + 3.3(%Mo + 0.5%W) + 16(%N)

The multipliers 3.3 & 16 used in the formula illustrate the relative strength of each element’s contribution to corrosion resistance compared to chromium. However, if a blade steel contains tungsten (W), there is the revised PREW formula that adds a 1.65 multiplier for W to more accurately reflects how that steel composition will resist corrosion.

PREW = %Cr + 3.3(%Mo) + 1.65(%W) + 16(%N)

However, in October 2019, KSN acknowledged that PREN actually predicts how well the steel will resist pitting corrosion, not surface oxidation (rust), which is of more interest to knife users. So Larrin went back to the drawing board and published a revised approach to calculating corrosion resistance, starting by executing a salt water spray test. After repeated applications of a 1% saline solution repeatedly sprayed onto his selection of test steels every 8 hours, he noted the final amount of rust that had developed over 48 hours. He rated the amount of visible rust on the test steels, assigning them a 1-10 score. Based on these results, he used thermodynamic modeling software, Thermo-Calc, to estimate the amounts of elemental Cr, Mo, W, and N in solution within the matrix of each steel and used that data to create his own new rust resistance equation below to derive a numeric value. Steels with values below 7 are not identified as stainless steels.

Rust resistance = %Cr + (1.6 * %Mo) + (0.8 * %W) + (6 * %N)

The unfortunate part (for me) is Larrin’s reliance on Thermo-Calc to get predicted amounts of Cr, Mo, W, and N in solution, not just simply in composition. The difference is how much of the 4 elements are bound in carbides vs in the steel matrix. I only have access to the compositional data for the various steels. Running his formula on compositional levels (which I tried, you know, just for kicks), produced rather different results in which his ranking data did not correlate to my PREN formula results. So, I was unable to create a calculated corrosion (oxidation) resistance prediction that correlated to the KSN rankings (and I feel just terrible about it).

That said, his new rankings data was not much different from his earlier, PREN-based data. There was no major change for the steels in this study, so for your entertainment and joy, I am including my calculated PREN/PREW values in the table below. Not that in my calculations below, I used the PREN equation for steels that had 0% W, but used the PREW equation when W was included in the steel composition.

| PREN Pitting Resistance Equation Scale |

|---|

| < 10 |

| 10 – 20 |

| > 20 |

Corrosion Resistance Table for Decent Budget Steel

These results are what was collected by my gathering of steel ranking websites data.

The Decent: Corrosion Resistance

| Blade Steel Family Types | Knife Steel Nerds | PREN/PREW Equations | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI D2 | 4.5 | 14.23 | 5 | 4 | 4 | 4 | 5 |

| • Bohler K110 | 14.64 | ||||||

| • Crucible CPM D2 | 4.5 | 14.79 | 5 | 4 | 5 | ||

| Alleima (Sandvik) 14C28N | 8.8 | 15.76 | 9 | 7 | 7.5 | 9 | |

| • NJSB Nitro-V | 7.6 | 14.76 | |||||

| • Alleima (Sandvik) 13C26 | 13 | 5 | 4 | ||||

| • Bohler AEB-L | 7.1 | 13 | 7 | 7 | 7 | ||

| Takefu VG 10 | 7.9 | 18.47 | 8 | 6 | 7 | 8 | |

| • 10Cr15CoMoV | 18.3 | ||||||

| Crucible 154CM | 7.2 | 27.28 | 7 | 6 | 5 | 7 | |

| • Crucible CPM 154 | 7 | 27.2 | 7 | 6 | 5 | 7 | |

| • Hitachi ATS-34 | 7 | 27.28 | 5 | 6 | |||

| Bohler N690 | 8.1 | 20.78 | 8 | 7 | 7 | 8 | |

| • Bohler N690Co | 19.79 | ||||||

| • Bohler N695 | 18.99 |

The 1st group of high alloy stool steels (D2 and family) are commonly called semi-stainless because of how much chromium they have. Unfortunately, they don’t have enough Cr to prevent rust. They have enough just to prevent the steels from immediately being covered in a red, crusty surface film (see my discussion of carbon steels coming up in Part 3!). But give it a bit of good, tender loving care, which translates to keeping the knife clean, wiping off all moisture from the blade and giving it regular light wipes of oil (you can use special, expensive stuff like the various commercial rust & corrosion preventive oils, but if you want to cheap out, you can make mineral oil, even coconut oil, do the trick. And no one ever complained about having a pocketknife that smells like a Piña Colada!

Aside from the D2 family of tool steels, all the remainder are stainless steels, and there are no poor performers.

In fact, many of these steels rank very well, especially 14C28N and N690. As such, Vinnie the Shiny Blade came out for a visit. The PREN data doesn’t always correlate to the new KSN rankings, but this is expected, and I discussed why in the paragraphs above the table.

Rockwell Hardness: The Decent

A discussion on measuring the hardness of steel could go on ad infinitum (sort of like where this post is going!). The hardness of steel can be extremely variable, depending upon its composition and the heat treatment it is given. Indeed, when steel is manufactured, before it is delivered to its knife manufacturing customer, the steel bar stock, sheets or plates are annealed. This heat treatment process makes the steel soft and malleable enough to easily cut blade blank profiles from the stock. The annealed malleability ensures the steel is easily machined by the blade manufacturer. After the blank has been cut and ground into its final shape, the blade heat treat process (which includes initial heat treatment in a controlled furnace, the quench, the optional cryo process, and finally the temper process) can begin to transform the crystals in the steel (known as grains) into the desired final form, which directly affects the steel’s toughness, its carbide development, and significantly hardens the blade from its initial, annealed state.

Hardness Scales

I already wrote about the various measurement scales and means by which to test the hardness of steel. This includes the Brinell, Knoop, Leeb, Vickers and Rockwell scales, with Rockwell C being the most common scale used for blade steel, although there are many Rockwell scales available for testing the hardness of various materials (who knew?). HRc has an effective measurement range from 20 to 68. Anything outside of that range will not be accurately measured using HRc. For example, the annealed steel barstock discussed in Part 1 are often delivered to customers in such a softened, malleable state that one must go to HRb to get a valid hardness scale measurement. If you ever see a reference to annealed steel coming in at HRc 15, rest assured that this is not an accurate hardness measurement of that steel. Such a steel will be more accurately measured in HRb, where the theoretical (not measured) HRc 15 is more or less the equivalent to HRb 93 (hardness conversion pages are available online). The hardest steel, CPM Rex 121, which can be hardened to a theoretical HRc 70, is technically beyond the top end of HRc. And if you are interested in a Sandrin tungsten carbide knife, the hardness of its blade goes beyond Rex 121, and at this point getting a measurement on the Vickers scale is more accurate. The HV hardness scale rating for the Sandrin would likely be at 1140 (the theoretical equivalent of HRc 71, as mentioned on the Sandrin website).

To do hardness testing, you need a hardness tester, naturally. The testing process typically involves compressing a probe into the steel to measure the resistance to the resulting indentation deformation. However, a proper, certified, professional hardness testing machine that correlates to a specific hardness scale can be an expensive piece of equipment.

This doodad, the Mitutoyo model 810-521-13, is pretty nice. It can measure Rockwell hardness down to a unit resolution of 0.01. Sweet. If you’re interested, it’ll only set you back $31,744.50, and naturally, shipping is not free. Now if I could afford this, I’d instead be the proud owner of so many Herman Knives, Winterblade knives, Shiro knives; heck, I’d even get myself a QSP Penguin, you know, just for kicks, because everybody should have a Penguin.

I do perform my own hardness testing using a slightly less expensive tester, a Portable Leeb Rebound tester.

Although it’s not automatic like the Mitutoyo, it’s a bit smaller, weighs less, and it does have an illuminated digital screen as does the Mitutoyo. It’s practically the same thing! It also comes with its own chonky, steel calibration block! And at a cost of just 0.6% of the larger, non-portable machine, I make it work for my needs.

Unfortunately, because hardness ratings must come from physical testing, there is no formulaic equation for a predictive calculation of the hardness of steel. And unfortunately, I don’t have samples of each of these blade steels to run my own comparative tests (care to donate to fix that?). But even if I did, I’d be testing a specifically treated knife blade rather than generic blade stock. As such, let’s look at the typical hardness ratings ranges from KSN and others on these Decent budget steels.

The Decent: Rockwell Hardness (HRc)

| Blade Steel Family Types | Knife Steel Nerds | A.G. Russell | Cedric & Ada | HRc Tests | Knife Informer | Knife Know It All | Knife PMI & HRc | Oishya | Pokes | Spyderco Forum | zKnives |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI D2 | 59-62 | 57-61 | 59.79 | 60 | 62 | 57-61 | 58-64 | 57-61 | 60.4 | ||

| • Bohler K110 | 58-60 | 58 | 58-60 | 58-64 | 58-60 | ||||||

| • Crucible CPM D2 | 59-62 | 57-59 | 61 | 62 | 58-64 | 60.8 | |||||

| Alleima (Sandvik) 14C28N | 62 | 57-60 | 57.99 | 57.2 | 59 | 55-62 | 55-62 | 55-62 | 59.4 | 55-62 | |

| • NJSB Nitro-V | 60.5 | 60.6 | 58-64 | 58-64 | 59.1 | 58-62 | |||||

| • Alleima (Sandvik) 13C26 | 57-69 | 59 | 58-60 | 58-60 | |||||||

| • Bohler AEB-L | 61-64.5 | 58.8 | 58.8 | ||||||||

| Takefu VG 10 | 61.5 | 59-61 | 57.5 | 60 | 59-61 | 58-60 | 59-61 | 59.2 | 57.9 | 60-62 | |

| • 10Cr15CoMoV | |||||||||||

| Crucible 154CM | 60 | 58-62 | 58.99 | 59.2 | 60 | 58-62 | 58-62 | 58-62 | 61 | ||

| • Crucible CPM 154 | 61 | 59-61 | 60.4 | 58.6 | 60 | 59-61 | 55-58 | 59-61 | 59-61 | ||

| • Hitachi ATS-34 | 61 | 59-61 | 60 | 59-61 | 59-61 | ||||||

| Bohler N690 | 62.5 | 60 | 58.77 | 58-60 | 56-58 | 60 | 57.7 | 58-60 | |||

| • Bohler N690Co | 57.4 | 58-60 | |||||||||

| • Bohler N695 | 61 | 57-59 |

These hardness ratings are not the theoretical minimum and maximum ranges that the optimistic steel manufacturers publish. These are (likely) measured ratings from actual testing, or at least I hope so, on given steel samples, and probably on actual knife blades. Given that some scores are single numbers rather than a range, it either means that only 1 blade was tested, or the data was averaged out, or the reviewer took their data from someone else who had averaged their data! Who knows? OF course, each type of steel has an optimum hardness range balanced for both hardness and toughness. When steels are not heat treated properly (or omit optimization steps, such as cryo treatments), then the hardness ratings can come in softer. Cryo takes time, time is expensive, and expensive costs cut into profits. Yup.

Generically speaking, the hardness ratings for the Decent budget steels are pretty good. No specific complaint here. Sterling the Strong Blade agrees.

Effect of Blade Coatings

Another factor potentially affecting hardness is whether or not the blade has a coating applied. While many knife reviewers parrot misinformation without understanding how blade coatings are applied, claiming that any coated blade will be 1 HRc point lower than uncoated blades, the truth is most blade finishes do not affect blade hardness at all. Very few coating types involve significantly high temperatures, and only a select few of those processes get hot enough to likely exceed the knife maker’s steel tempering temperatures. When that does happen, though, that high heating would actually de-temper (and potentially negatively change the hardness of the steel). If your knife has a blade coating consisting of one of the materials below, note that the blade steel hardness could be at risk for compromising the steel temper.

| Blade Finishes | Application Temperatures | Possible Effects on Temper |

|---|---|---|

| Titanium Carbonitride (TiCN) | 400°C to 450°C (750°F to 840°F ) | Likely to de-temper |

| Titanium Nitride (TiNi) | 400°C (752°F ) | Likely to de-temper |

| Spectrum | 204°C to 316°C (400 to 600°F ) | High potential to de-temper |

| Flamed | 149°C to 316°C (300 to 600°F ) | High potential to de-temper |

| Diamond-Like Carbon (DLC) | 200°C (392°F ) | May affect only low-temp tempered blades |

| Physical Vapor Deposition (PVD) | 200°C (392°F ) | May affect only low-temp tempered blades |

| Powder Coat | 150°C to 200°C (300°F to 400°F ) | May affect only low-temp tempered blades |

| Cerakote | 120°C to 150°C (250°F to 300°F ) | Very unlikely to affect blade temper |

| Gun Bluing | 145°C (295°F ) | Very unlikely to affect blade temper |

All the other, regular blade steel finishes that are not listed above either use process temperatures too low to be of worry, or are done cold, neither of which will affect HRc.

Ease of Sharpening: The Decent

This is one of those subjective assessments that people like to talk about. You’ll note that KSN has no input to offer here, as there is no scientific designation to this metric (hardness would seem to be mostly the same, and that is already covered), but I include it here as so many people look for this and so many publish ratings for this subjective metric.

This metric is problematic because the sharpening experience depends upon the hardness of the steel, the type, size, density and distribution of carbides in the steel, and the type sharpening media used. Use an aluminum oxide sharpening stone on any type of CPM Rex steel and you’re going to have a long, frustrating day. However, if you have a high-quality set of diamond stones, have no concerns. All blade steels, even the venerable steels CPM Rex 121 (HRc 67 – 70.5), ASP-60 (HRc 70) and Vanadis 60 (HRc 69), will bow down to your efforts—eventually. So, take the following data as you will. Meh.

The Decent: Ease of Sharpening

None of these steels are particularly difficult to sharpen, so Eddie the Easy to Sharpen Blade casually saunters in with his oh so cool way.

Of course, when you attempt to sharpen blades on lower grade (aka softer) sharpening stone materials, such as natural oilstone, aluminum oxide, whetstones, ceramic rods, or silicon carbide, you will struggle to sharpen blades that are 63 HRc and higher. So, stick with high quality diamond stones (not cheap garbage in which the diamond density is low and/or the diamonds are so poorly embedded that they just fall off). Also use high-quality, firm leather strops coated with high-quality diamond paste (diamond density counts here, too), and you’ll be able to sharpen the hardest steels.

Now do note that very soft steels can be unintuitively very difficult to sharpen. It’s not because removing blade material is a problem, quite the opposite. It’s because removing the sharpening burr from soft steel is shockingly difficult. Because of the steel softness, the wide burr created in the material removal process tends to simply flop over from side to side, perhaps even grow, as the sharpening process continues. That inability to remove the burr prevents the blade from actually getting to a fine apex, aka sharp. So, despite Eddie’s appearance above, Henry the Hard to Sharpen Blade has entered the room.

Remember that removing metal is not the same as sharpening. Creating a burr and then skillfully removing that burr to get a good apex is the definition of sharpening.

Elemental Composition: The Decent

As we saw in Part 1, the elements found in the steel composition and the percentages of each have a substantial effect on the properties of the finished knife blade. Chromium affects stainlessness. Carbon affects hardness. Molybdenum and manganese increase hardenability. Vanadium and tungsten form extremely hard carbides. Nickel increases toughness. Of course, this is a great simplification. And it’s important to note that too much of a given element can produce deleterious results, such as decreasing toughness, decreasing machinability, increasing costs, complicating the heat treatment process, and much more. Steel is an elemental compromise of both positive and negative traits, and each variation was created to fill a specific, sometimes niche, role.

Most steels used in blades today were not invented for use in knives; instead, they were re-purposed for use in knife blades much later on. Some repurposed steels are better than others in their role as knife blades, and the basic costs of manufacturing and machinability contribute at least as much as the desired steel properties to the decisions made by knifemakers on which steel to use.

Phosphorus and sulfur, highlighted in red, are both regarded as unintended impurities. Very low levels may may be tolerated in some steels, and not tolerated at all in others. There appears to be positive correlation to less expensive, lower quality steel usually having higher amounts of these impurities.

Elemental Composition Table for Decent Budget Steel

In the table below are the elemental components of the budget blade steels in the Decent category. By looking at these charts, you will eventually begin to see patterns of combinations, such as Cr and C for stainlessness, and intuitively know how well the blade will work for corrosion resistance. Same goes for higher levels of W and V for very hard carbides, and correctly predict the levels of edge retention.

The Decent: Elemental Composition

| Blade Steel Family Types | Base | Carbon (C) % | Chromium (Cr) % | Cobalt (Co) % | Copper (Cu) % | Manganese (Mn) % | Molybdenum (Mo) % | Nickel (Ni) % | Niobium (Nb) % | Nitrogen (N) % | Phosphorus (P) % | Silicon (Si) % | Sulfur (S) % | Tungsten (W) % | Vanadium (V) % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI D2 | Fe | 1.50-1.60 | 11.50-12.00 | 0 | 0 | 0.15-0.45 | 0.60-0.90 | 0 | 0 | 0 | 0.00-0.03 | 0.10-0.40 | 0.00-0.03 | 0 | 0.90-1.10 |

| • Bohler K110 | Fe | 1.45-1.65 | 11.00-13.00 | 0 | 0 | 0.30-0.60 | 0.70-0.90 | 0 | 0 | 0 | 0.00-0.03 | 0.20-0.40 | 0.00-0.02 | 0 | 0.70-1.00 |

| • Crucible CPM D2 | Fe | 1.55 | 11.50-12.00 | 0 | 0 | 0.4 | 0.90-0.95 | 0 | 0 | 0 | 0.03 | 0.4 | 0.03 | 0 | 0.8 |

| Alleima (Sandvik) 14C28N | Fe | 0.62 | 14 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0.11 | 0.03 | 0.2 | 0.01 | 0 | 0 |

| • NJSB Nitro-V | Fe | 0.66-0.70 | 12.70-13.30 | 0 | 0 | 0.60-0.70 | 0 | 0 | 0 | 0.10-0.12 | 0.00-0.02 | 0.30-0.50 | 0.00-0.01 | 0 | 0.05-0.10 |

| • Alleima (Sandvik) 13C26 | Fe | 0.68 | 13 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 | 0.03 | 0.4 | 0.01 | 0 | 0 |

| • Bohler AEB-L | Fe | 0.67 | 13 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0.03 | 0.4 | 0.02 | 0 | 0 |

| Takefu VG 10 | Fe | 0.95-1.05 | 14.50-15.50 | 1.30-1.50 | 0 | 0.5 | 0.90-1.20 | 0 | 0 | 0 | 0.03 | ? | ? | 0 | 0.10-0.30 |

| • 10Cr15CoMoV | Fe | 0.95-1.05 | 14.50-15.50 | 1.30-1.80 | 0 | 0.30-0.50 | 0.80-1.20 | 0.00-0.25 | 0 | 0 | 0.03 | 0.00-0.45 | 0.03 | 0 | 0.25-0.35 |

| Crucible 154CM | Fe | 1.05 | 13.50-14.00 | 0 | 0 | 0.5 | 4 | 0 | 0 | 0 | 0.03 | 0.30-0.80 | 0.03 | 0.00-0.40 | 0.00-0.40 |

| • Crucible CPM 154 | Fe | 1.05 | 13.50-14.00 | 0 | 0 | 0.5 | 4 | 0 | 0 | 0 | 0.03 | 0.8 | 0.03 | 0.00-0.40 | 0.00-0.40 |

| • Hitachi ATS-34 | Fe | 1.05 | 14 | 0 | 0 | 0.4 | 4 | 0 | 0 | 0 | 0.03 | 0.35 | 0.02 | 0 | 0 |

| Bohler N690 | Fe | 1.07 | 17.00-17.30 | 1.5 | 0 | 0.4 | 1.1 | 0 | 0 | 0 | ? | 0.4 | ? | 0 | 0.1 |

| • Bohler N690Co | Fe | 1.05-1.07 | 16.00-17.30 | 1.50-1.65 | 0 | 0.4 | 0.80-1.10 | 0 | 0 | 0 | ? | 0.4 | ? | 0 | 0.00-0.10 |

| • Bohler N695 | Fe | 0.90-1.20 | 16.00-19.00 | ? | 0.00-0.30 | 0.50-1.00 | 0.00-0.80 | 0.00-0.60 | ? | ? | 0.00-0.04 | 0.53-1.00 | 0.00-0.03 | 0.00-0.20 | 0.00-0.20 |

KSN Round-Up: The Decent

Lastly, as I have relied so much on the authoritative assessments of Larrin Thomas from KnifeSteelNerds.com, rounding up all the KSN ratings data together in 1 table for the Decent steels can provide a clearer picture of how the compromises in steel properties show up in the blades.

The high toughness of the 14C28N and related steels is countered by their disappointingly low edge retention ratings. This is a perfect demonstration of the compromises made between the 3 main blade steel properties work. Most often, at best, you can get 2 reasonably good ratings along with one fairly poor rating. Sometimes, though, with lower-grade steels, you might only get 1 good rating, and with antiquated steels, perhaps none! Welcome to the wacky world of knife blade steels.

The Decent: KSN Round-Up

| Toughness | Edge Retention | Corrosion Resistance | Rockwell Hardness (HRc) | ||||

|---|---|---|---|---|---|---|---|

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft-lbs. @ HRc | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Knife Steel Nerds | PREN/PREW Equations | Knife Steel Nerds |

| AISI D2 | 3.5 | 5-3 @58.75-63.4 | 5 | 485-500 @ 59.1-60.5 | 4.5 | 14.23 | 59-60.5 |

| • Bohler K110 | 14.64 | ||||||

| • Crucible CPM D2 | 5.5 | 11.75 @ 62.5 | 5 | 4.5 | 14.79 | 59.75 | |

| Alleima (Sandvik) 14C28N | 9 | 30 @ 60.75 | 3 | 420 @ 62 | 8.8 | 15.76 | 62 |

| • NJSB Nitro-V | 7.5 | 22-9 @ 61.25-63.6 | 3 | 360 @ 60.5 | 7.6 | 14.76 | 60.5 |

| • Alleima (Sandvik) 13C26 | 9 | 37.5-12 @ 60-64 | 3 | 358-445 @ 61-64.5 | 13 | ||

| • Bohler AEB-L | 9 | 37.5-12 @ 60-64 | 3 | 358-445 @ 61-64.5 | 7.1 | 13 | 61-64.5 |

| Takefu VG 10 | 4 | 5 @ 61 | 4.5 | 477 @ 61.5 | 7.9 | 18.47 | 61.5 |

| • 10Cr15CoMoV | 18.3 | ||||||

| Crucible 154CM | 3.5 | 5 @ 60.1 | 4.5 | 495 @ 61 | 7.2 | 27.28 | 60 |

| • Crucible CPM 154 | 5 | 10-6 @ 60-64.1 | 4.5 | 495 @ 61 | 7 | 27.2 | |

| • Hitachi ATS-34 | 7 | 27.28 | 61 | ||||

| Bohler N690 | 3.5 | 4 @ 62.5 | 4.5 | 8.1 | 20.78 | 62.5 | |

| • Bohler N690Co | 19.79 | ||||||

| • Bohler N695 | 18.99 | ||||||

Knife Karen Nitpicks

This has been a long, detailed exploration of the commonly available budget steels I categorized as Decent. Was this interesting or helpful to you? No? Well, I will need to speak your manager. Call them!

- I was able to run the calculations for the PREN & PREW equations that Larrin Thomas originally used to get corrosion resistance values for steels for which I had not seen any ratings, which is cool. But then some fool told Larrin that PREN was not the right measurement, and he needed to redo his work. He used the thermodynamic modeling software tool, Thermo-Calc, to calculate his new and improved equation results. But I don’t have Thermo-Calc, and thus I was unable to do the right calculations myself. Crap! Why isn’t this information easier to access for peasants like me? I am going to write a very serious letter about this!

- Speaking of getting my own test results, I don’t have a Charpy testing tool, nor do I have a high-end hardness testing machine. Why not? Don’t I deserve it? Who’s in charge of this inequity?

- Why do so many people make the generic assumption that any coating applied to pocketknife blade steels automatically reduce the blade’s hardness rating by 1 full point? This is not true! Well, not universally true. But I don’t typically see budget knife blades coated with either Titanium Carbonitride (TiCN) or Titanium Nitride (TiNi), so unless a blade was tempered at temperatures under 200°C (400°F), hardness reduction by de-tempering is not always a sure thing with blade coatings (the applications of both DLC and PVD can be that hot, but other coatings, not so much).

Verdict

The performance factor properties of the budget blade steels in the Decent category are, well, decent. Not superlative, not premium, not even great, but just decent. The ratings of these blade steels for toughness were quite mixed. Some were actually pretty impressive, while others sucked straws. As for edge retention, none rated better than middling, and a few (I’m looking at you, the blade steels that had impressive toughness scores!) were pretty sad. Lastly, since all of these steels are considered stainless, the rust resistance ratings were almost all between average to quite good, although the vaunted D2 varieties were definitely in the back of the pack (they are often described as “semi-rust resistant”. Yeah, quite semi!). And for what it’s worth, the D2 also had the lowest potential hardness ranges of all the Decent steels.

Steels in the 14C28N “family” rated very well overall, especially 14C28N and Nitro-V. The other families of steels led by VG 10, 154CM & N690 were only notable for their stainlessness, in which 154CM and family led the pack by a wide margin. Otherwise, toughness and edge retention ratings for those steels were distinctly unimpressive. In truth, the least impressive family of the Decent steels were D2. Its ratings were uniformly middle of the road – or worse. It was the Decent category leader for edge retention, but at a mere 5 out of 10, it barely edged out 154CM and family by a half-point, while 154CM had strong scores in corrosion resistance.

One interesting thing to note was how the 2 particle metallurgy steels, CPM D2 and CPM 154, compared to their ingot-formed counterparts, D2 and 154CM. The edge retention and rust resistance scores were pretty much identical between versions. However, the toughness ratings between the PM and ingot steels were remarkably different. In both cases, the PM variants had 2x the toughness rating scores (resistance to chipping, cracking & breaking) than did the ingots. As discussed in Part 1, the advantage of PM steels, at least with regard to toughness, is that the size and distribution of the carbides in the steel matrix are smaller and more evenly dispersed. If you have a chance to pick up a PM version of these steels for your next budget pocketknife, you’ll enjoy the improved toughness of those steels.

What you saw here in this comparative analysis of blade steel property performance factors is the common properties compromise in blade steel metallurgy. Blade steels are rated against the 3 key properties: toughness, edge retention, and corrosion resistance. At best (unless we’re talking MagnaCut), your knife’s blade steel might have 2 of the 3 properties that have positive ratings, but it should be expected to get a fairly disappointing rating for the 3rd property. However, given in this 3-part series of posts we are talking about blade steels in the budget realm, it’ll be a fairly rare occurrence to get 2 out of the 3 property ratings that are very strong.

Verdict? For all the reasons above, as a Decent steel in the budget category, Alleima (Sandvik) 14C28N is quite impressive, with Nitro-V following close behind. These are extremely tough and very rust resistant steels, but unfortunately, they have quite poor edge retention ratings, so don’t be surprised that your 14C28N or Nitro-V blade dulls quite quickly. Both will need regular sharpening & stropping. Low edge retention is their Achilles Heel. If you want a little bit better edge retention, then look at CPM 154. This steel has a middling toughness score, a very good corrosion resistance rating, and a middling edge retention rating, with is a significant step-up from the 14C28N family.

The bottom line is that if you want a pocketknife that will give you decent performance across 2 of the 3 key performance factor ratings and you refuse to pay more than $100, you can do it. Such a knife won’t be the cheaper half of the cost spectrum, but it’s certainly doable, if you know what to look for.

Coming up next: In Part 3 of this Budget Blade Round-Up 2024 series, we will both laugh and cry, this is where we cover in detail both the Mediocre and the Junk knife steel blade categories. Hey, it’s already published, so let’s go there now! Enjoy! ![]()