What would you do if you had a new C-note, a genuine Benjamin burning a hole in your pocket and you wanted to buy a new budget pocketknife? Would you know which to pick? Do you know what blade steel to get?

In Part 1 of the 2024 Budget Blade Round-Up series, I discussed the methodology I used to collect a large inventory of Budget-level (all knives under $100) pocketknife blade steels from 17 online pocketknife retailers (there originally were 40, but most of the 23 others had uselessly crappy website search filters, and a small few had pathetically small budget pocketknife inventory levels). We also looked at the important blade steel performance factors that should be considered before buying your next budget knife. Now let’s apply that information to the actual budget blade steels I collected.

I gathered the most common of these budget blade steels from the inventory can assigned them into 3 basic categories:

- The Decent,

- The Mediocre, and

- The Junk. Yep, I said it.

I then looked at the most common steels per category and then gathered identical (and very similarly related) groups of blade steel “families“ around these most common steels. Now I’m ready to do some real steel spiel.

In Part 2, I took a detailed look at the Decent budget blade steels found in the online retailer inventory. I compared those steels by the 3 key steel properties, as rated by those who should know (well, KnifeSteelNerds.com, and a few other blogs and online articles): Toughness, Edge Retention, and Corrosion Resistance. I then examined the ratings of those “Decent” steels on Rockwell C hardness, Ease of Sharpening, and Elemental Composition. And for funsies, I gathered the collected ratings from the authoritative KSN data.

In this, the 3rd and final post in this interminable series, I now look at the Mediocre budget blade steels, giving them the same thorough treatment as was done for the Decent steels in Part 2. These steels are the basis of the pedestrian blades in the Budget category. If you really are cheap or have little money to spend, well, these will do okay, as long as you don’t ask too much of them. And once the Mediocre have been covered, we’ll take a stroll down to Junk Junction, where the garbage of budget blades live. I’ll do the same analysis for Junk that I did for the 2 better categories. But don’t expect much good news there. The category is aptly named. Finally, after wallowing in that fetid mire for a while, we explore the periphery of the budget knife blade steel inventory and have some fun with that.

Are you ready? No? Aw, who cares. I’m not waiting. Let’s get on with it.

TL;DR

A budget knife need not be a gas station junker. Those pieces of crap are just pieces of crap. If you can’t afford any of the Decent budget knife blade steels outlined in Part 2, then we’ll use this opportunity to have a look at the Mediocre category of budget blade steels for potential buys. I will also explore the budget Junk steels category, which you really should avoid. There’s value and then there’s no value. You get the point, right? If you actually want a true, low-cost, budget knife that will do little more than very light work (which definitely rules out gas station knives), study the Mediocre blade steels section with me. This data will help you get a basic, functional knife for your very small amount of money.

Pros

- Typical blade steels possess 3 key desired quality properties, although the levels of these properties can often be at odds with one another. You’ll probably get 1 key property out of 3 in these categories of blade steels. As I said before, you will need to prioritize which property is most important to you and go from there:

- Toughness. Resistance to fracturing or chipping; brittleness

- Edge Retention. Resistance to wear from abrasion; how long the edge stayed sharp

- Corrosion Resistance. Resistance to damage from oxidation and other factors; rust.

Note: You can learn more about knife steel properties in the section titled, Sidebar: 3 Key Properties of Knife Steel – Pick 2 from my earlier post about the Mikov Kostka funny folder knife.

- Ease of sharpening is also an important feature, but much less so in these levels of budget knife steels, as they won’t be overly hardened (or in some cases, not very hardenable), but it will be ridiculously hard to remove that blasted sharpening burr!

Cons

- Finding blades that have good property rankings when made of poor-quality steel (and there are a lot of them at these levels of the budget blade category) will be challenging. Some steels just truly suck. In this Mediocre and lower territory, if you’re lucky enough to get 1 blade steel property that rates OK, the rest are mostly likely to be more or less crap. Junk steel blades can be even worse!

- You will find that some knife blades (like those in this lower categories round-up) can’t physically come to a sharpened edge because the steel is too damn soft!

- Looking for a respectable, budget working knife will almost always rule out the inclusion of bats, dragons, skulls and snakes (oh boo!).

The Mediocre: Middling Budget Blade Steels

I just covered in Part 2 what I euphemistically called the Decent budget blade steels. I now take a step down in quality and performance to explore the next category I call the Mediocre. The Mediocre aren’t total garbage, but they are certainly not anything to write home about (who writes home these days, anyway). These are the steels you should look for when you are shopping for cheap, cheap, cheap budget knives. You really don’t want to go any lower than this. I’ll cover why later on.

Will these steels cut? Sure. For a while. A short while. But there is good news here! You’ll really become proficient with your knife sharpening skills. As they say, practice makes perfect, and you’ll have plenty of opportunities for practice because of the need to do a lot of sharpening and stropping on these blades.

Similar to what I said about the Decent category blades, do not use any of the blade steels found here for anything but basic cutting purposes. No screwing, no chiseling, no prying. This is a basic knife and should be reserved for cutting the tape on Amazon boxes, opening up paper letter envelopes, cutting loose threads off your clothes, dividing your tuna fish sandwich, and not much more. If money is the biggest factor for you when shopping for your next budget knife, let’s see if we can find something, anything, that’ll fit your needs.

The Mediocre: Introduction

| Blade Steel Family Types | Quantities =< $99 | Aggregate Total | Type | Class | Process | Manufacturer | Invented | Country |

|---|---|---|---|---|---|---|---|---|

| 8Cr13MoV | 3,719 | 5,407 | Stainless Steel | Ingot | Ahonest Changjiang | Late 1990s | CN | |

| • Aichi AUS-8 | 1,055 | Stainless Steel | Ingot | Aichi | Late 1970s | JP | ||

| • 8Cr14MoV | 345 | Stainless Steel | Ingot | Ahonest Changjiang | Late 2000s | CN | ||

| • Aichi AUS-8A | 283 | Stainless Steel | Ingot | Aichi | Late 1960s | JP | ||

| • 8Cr15MoV | 5 | Stainless Steel | Ingot | Ahonest Changjiang | Late 2000s | CN | ||

| Latrobe Case Tru-Sharp | 3,022 | 3,625 | Stainless Steel | High carbon | Ingot | Latrobe | 1964 | US |

| • Latrobe 420HC | 603 | Stainless Steel | High carbon | Ingot | Latrobe | 1964 | US | |

| 9Cr18MoV | 839 | 1,330 | Stainless Steel | High carbon | Ingot | Ahonest Changjiang | Late 1990s | CN |

| • Artisan Cutlery AR-RPM9 | 404 | Stainless Steel | High carbon | Spray Foam | Artisan Cutlery | 2020 | US | |

| • AISI 440B | 87 | Stainless Steel | High carbon | Ingot | various | 1926 | US | |

| AISI 440C | 617 | 1,203 | Stainless Steel | High carbon | Ingot | various | 1935 | US |

| • Aichi AUS 10A | 282 | Stainless Steel | High carbon | Ingot | Aichi | Late 1980s | JP | |

| • Aichi AUS 10 | 247 | Stainless Steel | High carbon | Ingot | Aichi | Mid 1970s | JP | |

| • CTS BD1 | 54 | Stainless Steel | High carbon | Ingot | Carpenter | Early 2000s | US | |

| • 9Cr18 | 3 | Stainless Steel | High carbon | Ingot | Ahonest Changjiang | Late 1990s | CN |

All the steels but one in this category are ingot steel. Ingot steels are noted for their uneven cooling within their molds. The outside cools faster than the interior, and that cooling difference allows for elemental segregation, which produces larger sizes of carbides. That’s not so good for toughness, as crack lines form around the boundaries of carbides. This is why particle metallurgy steels were developed, to solve for the inherent toughness problem with ingot steel.

In the Mediocre blade steels list above, one product, AR-RPM9, used to be commonly identified as the least expensive PM steel on the market, as told by its inventor, the company Artisan Cutlery, whose manufacturing factory is located in Yangjiang, Guangdong, China. Well, that myth was busted in May, 2024 by the preeminent knife steel metallurgist and inventor of CPM MagnaCut steel, Dr. Larrin Thomas, in his article on his blog, KnifeSteelNerds.com, titled, AR-RPM9 Knife Steel is False Advertising. Larrin conducted an analysis of the composition, the grain structure, carbide distribution, and properties performance of AR-RPM9. He revealed to the world that AR-RPM9 is not in fact PM steel. Its carbides are far too large. Instead, it’s a variety of spray form steel, a metallurgical manufacturing technology that isn’t ingot-based, but isn’t particle metallurgy-based, either. It’s sort of in between these 2 processes. Spray form steel is a spray-based process that differs from PM in that PM steel is a technology where molten steel is sprayed in a nitrogen-filled chamber where it quickly cools into very fine powder-like particles, which later are compressed and heated to form an ingot, albeit one with very fine and evenly distributed carbides.

Spray form differs in that its molten steel-nitrogen gas spray, in a pre-cooled state, is applied to a table that lowers as it collects the material, which becomes the ingot once complete. The formation of the ingot while still very hot results in steel grain structures that are not as fine as PM steel, but are finer than ingot steel. While there was no specific KSN test data for AR-PRM9, Larrin reports that it should perform close to 440C levels, or perhaps slightly lower in ratings, which is also included in the Mediocre category along with AR-RPM9.

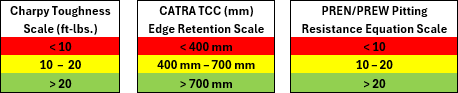

Toughness: The Mediocre

I already covered what toughness means for blade steel in the previous post. If you are just browsing this article instead of reading it through (shame on you! It took me a long time to write all this crap!) and you want to understand what I mean by toughness and/or what ft-lbs. @ HRc means, read the section in Part 2 called Measuring Toughness, then come back here. Easy, peasy, sleazy, squeezy. Also remember that not all sites from where I got my ranking data rated every blade steel I am covering. When there is no data there, there is no data here. Capiche?

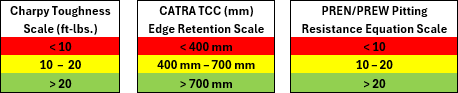

| Charpy Toughness Scale |

|---|

| < 10 ft-lbs. |

| 10 – 20 ft-lbs. |

| > 20 ft-lbs. |

The Mediocre: Toughness

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft-lbs. @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| 8Cr13MoV | 6 | 16 @ 60 | 6 | 6 | 6 | 6.5 | 6 |

| • Aichi AUS-8 | 6 | 16 @ 60 | 6 | 8 | 6 | 7 | 6 |

| • 8Cr14MoV | 6 | 16 @ 60 | 6 | ||||

| • Aichi AUS-8A | 6 | 16 @ 60 | |||||

| • 8Cr15MoV | |||||||

| Latrobe Case Tru-Sharp | 9 | 41 @ 57.5 | |||||

| • Latrobe 420HC | 9 | 41 @ 57.5 | 8 | 4 | |||

| 9Cr18MoV | 8 @ 59 | ||||||

| • Artisan Cutlery AR-RPM9 | 12-8 @ 59 | ||||||

| • AISI 440B | |||||||

| AISI 440C | 3.5 | 6-5 @ 58.9-63.5 | 4 | 7 | 5 | 7 | 4 |

| • Aichi AUS 10A | |||||||

| • Aichi AUS 10 | |||||||

| • CTS BD1 | 5 | 0 | 6 | 5 | |||

| • 9Cr18 |

A quick review of the Mediocre steel Toughness rankings reveals that most are meh, a couple are pretty good, and 1 is crap! This averages out to a mediocre toughness rating for the Mediocre budget steels, which brings out Michael the Mediocre Knife for a visit. Hi, Mediocre Mike! (Don’t worry, he doesn’t understand anything he’s told as he‘s always confused.)

In the Mediocre category, the Case Tru-Sharp / Buck 420HC steel scores are pretty tough with a rating of 9! Not bad, boys! But don’t get big heads about it. There’s more data coming up that will bring you down to earth again. Hard.

The 8Cr13MoV and related steels are middling in terms of resistance to fracturing and chipping. Only the 440C and its related steels are more than a bit sub-par here. In terms of brittleness, they’re not as fragile as a Doritos corn chip, but they are closer than you think.

Edge Retention: The Mediocre

And here we are, the most important metric to so many budget knife users. How well do these Mediocre blade steels hold their edge? You know, the one and only job knives are supposed to do, cut stuff with their edge? Cut stuff over time, repeating that process over and over? Well, as it turns out, these blades range from inferior to crap. Not horrid crap, but that slightly less offensive kind of crap that normally makes you feel pretty grossed out, but you still know it could be worse. Yeah, sub-mediocre crap.

As you know, I hate to repeat myself, be redundant, repetitious, or tautological, so I won’t reiterate here my discussion on what edge retention is or what the CATRA TCC (mm) @ HRc means. But if you really don’t know, I suggest you take a glance at the section CATRA TCC (mm) Test in Part 2 and catch up with the few folks who have been diligently reading through all this superfluous, prolix pedantic garrulity.

| CATRA TCC Edge Retention Scale |

|---|

| < 400 mm |

| 400 mm – 700 mm |

| > 700 mm |

The Mediocre: Edge Retention

| Blade Steel Family Types | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| 8Cr13MoV | 3 | 392 @ 61 | 3 | 5 | 1 | 3.25 | 3 |

| • Aichi AUS-8 | 3 | 392 @ 61 | 3 | 5 | 2 | 3.25 | 3 |

| • 8Cr14MoV | 3 | 392 @ 61 | 2 | ||||

| • Aichi AUS-8A | 3 | 392 @ 61 | |||||

| • 8Cr15MoV | |||||||

| Latrobe Case Tru-Sharp | 2.5 | ||||||

| • Latrobe 420HC | 2.5 | 2.5 | 3 | ||||

| 9Cr18MoV | |||||||

| • Artisan Cutlery AR-RPM9 | |||||||

| • AISI 440B | |||||||

| AISI 440C | 4.5 | 405-455 @ 56-62.9 | 5 | 6 | 3 | 4 | 5 |

| • Aichi AUS 10A | |||||||

| • Aichi AUS 10 | |||||||

| • CTS BD1 | 5 | 4 | 3 | 5 | |||

| • 9Cr18 |

The steel with the best edge retention rating is 440C, and it is still below average. But the Tru-Sharp / 420HC steels that were so proud of their toughness rating are now begging for forgiveness. How quick the mighty do fall. 2.5? Are you kidding me, Case & Buck? What do you put in the blade? Lead? It sure isn’t gold! 2.5 is a disgrace. No wonder these brands are moving to more modern blade materials and designs. What was once premium is now junk in the gutter.

Now we are visited again by Cullen the Dull Knife. Even he is disgusted with those ratings.

Corrosion Resistance: The Mediocre

Now this should be the best section here in the Mediocre budget steels, as everything is stainless steel, and the ratings don’t disappoint, unless you are more interested in quantity over quality. There’re hardly any ratings to compare, although other steels in the same family group should generally quite similar. And if you read in Part 2 about the corrosion resistance of Decent steels, you know how un-relevant the PREN / PREW equation scores are, but nevertheless, I still have them here. Why? For that, you need to read the section PREN / PREW Equation. You’re welcome!

| PREN Pitting Resistance Equation Scale |

|---|

| < 10 |

| 10 – 20 |

| > 20 |

The Mediocre: Corrosion Resistance

| Blade Steel Family Types | Knife Steel Nerds | PREN/PREW Equations | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| 8Cr13MoV | 14.41 | 7 | 7 | 6 | 5.5 | 7 | |

| • Aichi AUS-8 | 14.41 | 7 | 7 | 7 | 4 | 7 | |

| • 8Cr14MoV | 14.48 | 6 | |||||

| • Aichi AUS-8A | 14.41 | ||||||

| • 8Cr15MoV | 14.41 | ||||||

| Latrobe Case Tru-Sharp | 8 | 13 | |||||

| • Latrobe 420HC | 8 | 13 | 6.5 | 8 | |||

| 9Cr18MoV | 21.8 | ||||||

| • Artisan Cutlery AR-RPM9 | 21.3 | ||||||

| • AISI 440B | 19.48 | ||||||

| AISI 440C | 7.5 | 19.48 | 8 | 8 | 7 | 5.25 | 8 |

| • Aichi AUS 10A | 14.41 | ||||||

| • Aichi AUS 10 | 14.41 | ||||||

| • CTS BD1 | 16.74 | 7 | 6 | 6 | 7 | ||

| • 9Cr18 | 18 |

Given the rust resistance ratings we have here, we bring back Vinnie the Shiny blade, who’s fairly impressed with what he sees.

If you read about how PREN equations in Part 2 do not actually measure resistance to rust, but instead measure resistance to corrosive pitting, and you believe my scoring (don’t act crazy, now!), then these steels are all largely in the same range. Very similar middling to decent ratings. Meh. OK. Moving on…

Rockwell Hardness: The Mediocre

Are you familiar with Rockwell Hardness scales? Yeah? Cool. For the rest of you browsing-style readers, learn all about it by going to section Hardness Scales in Part 2. And that’s all I have to say about that.

The Mediocre: Rockwell Hardness (HRc)

| Blade Steel Family Types | Knife Steel Nerds | A.G. Russell | Cedric & Ada | HRc Tests | Knife Informer | Knife Know It All | Knife PMI & HRc | Oishya | Pokes | Spyderco Forum | zKnives |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 8Cr13MoV | 60-64.5 | 58-60 | 57.84 | 57.2 | 58 | 58-59 | 56-59 | 58-59 | 58.9 | ||

| • Aichi AUS-8 | 60-64.5 | 57-59 | 57.66 | 57.8 | 58 | 57-59 | 58-59 | 57-59 | 60.3 | ||

| • 8Cr14MoV | 60-64.5 | 57.84 | 56-59 | ||||||||

| • Aichi AUS-8A | 60-64.5 | 59 | 56.9 | 58-59 | |||||||

| • 8Cr15MoV | 58-59 | ||||||||||

| Latrobe Case Tru-Sharp | 57.5 | ||||||||||

| • Latrobe 420HC | 57.5 | 56-58 | 56.8 | 58.2 | 56 | 56-58 | 55-62 | 56-58 | 59 | ||

| 9Cr18MoV | 58-60 | 59.02 | 57.2 | 58-60 | 58-60 | 58-60 | |||||

| • Artisan Cutlery AR-RPM9 | 59.9 | 58-60 | 59.4 | ||||||||

| • AISI 440B | 57-59 | 57-59 | 57-59 | ||||||||

| AISI 440C | 56-63 | 57-59 | 57.41 | 57.8 | 58 | 57-59 | 58-60 | 57-59 | |||

| • Aichi AUS 10A | 59.5 | 59.3 | |||||||||

| • Aichi AUS 10 | 58-60 | 59.4 | 58-60 | 58-60 | 59 | ||||||

| • CTS BD1 | 58-60 | 58.7 | 59.1 | 59 | 58-60 | 58-59 | 58-60 | 59 | |||

| • 9Cr18 |

So I lied. I have more to say. Let’s look at the hardness ratings of these various steels. The potential hardness of the 8Cr13MoV family of steels look pretty good, even though what you will typically get on a pocketknife with this blade steel is not anywhere close to that high (to get hardness up so high costs time and money!). But do recall the same steels’ relatively poor edge retention ratings above. As I mentioned previously, the edge retention and hardness metrics are not one and the same. Remember that the types, size, density and distribution of carbides within the steel will play a significant role in edge retention. That all said, take a look at the Tru-Sharp & 420HC steels. 57.5. Definitely no award winners here. I guess this is in part why these steels landed in the Mediocre section. Yawn.

Ease of Sharpening: The Mediocre

There’s not a whole lot of data here, but rest assured that every steel in this list would rank pretty high. This correlates to the relatively soft HRc scores found above.

The Mediocre: Ease of Sharpening

It’s easy to remove blade material when that material is soft. But as I mentioned earlier, sharpening is not just removing blade material, but in fact is resetting the blade apex.

You would think this steel softness makes sharpening easy, which is why Eddie the Easy to Sharpen Blade joins us. BUT…

Soft steels will often resist letting go of the burr, and in that case, the blade is very hard to sharpen. It has a very thin-edged, everlasting burr. Depending on whether the remaining burr is pointing straight down or has folded over on its side, this is not sharpening.

So, in fact, this perpetual burr makes these soft steels rather hard to actually sharpen. And with that, we are joined by Henry the Hard to Sharpen Blade. These dudes seem to run together in the Budget blade steels category. For a better explanation and a cool demo, just take a look at Alex Garland’s excellent video on this topic.

What else is there to say? Nothing. And we continue…

Elemental Composition: The Mediocre

Since the elemental composition of a steel and its balance of each element greatly affects so many of its key properties, I bring you this. Interested? Well, here you go.

The Mediocre: Elemental Composition

| Blade Steel Family Types | Base | Carbon (C) % | Chromium (Cr) % | Cobalt (Co) % | Copper (Cu) % | Manganese (Mn) % | Molybdenum (Mo) % | Nickel (Ni) % | Niobium (Nb) % | Nitrogen (N) % | Phosphorus (P) % | Silicon (Si) % | Sulfur (S) % | Tungsten (W) % | Vanadium (V) % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8Cr13MoV | Fe | 0.70-0.80 | 13.00-14.50 | 0 | 0 | 1 | 0.10-0.30 | 0.2 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.25 |

| • Aichi AUS-8 | Fe | 0.70-0.75 | 13.00-14.50 | 0 | 0 | 0.5 | 0.10-0.30 | 0.49 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.26 |

| • 8Cr14MoV | Fe | 0.75-0.80 | 13.50-14.00 | 0 | 0 | 0.5 | 0.20-0.25 | 0 | 0 | 0 | 0.04 | 0.5 | 0.02 | 0 | 0.10-0.15 |

| • Aichi AUS-8A | Fe | 0.70-0.75 | 13.00-14.50 | 0 | 0 | 0.5 | 0.10-0.30 | 0.49 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.26 |

| • 8Cr15MoV | Fe | 0.70-0.75 | 13.00-14.50 | ? | ? | 0.5 | 0.10-0.30 | 0.49 | ? | ? | 0.04 | 1 | 0.03 | ? | 0.10-0.26 |

| Latrobe Case Tru-Sharp | Fe | 0.46 | 13 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | ? | 0.4 | ? | 0 | 0.3 |

| • Latrobe 420HC | Fe | 0.46 | 13 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | ? | 0.4 | ? | 0 | 0.3 |

| 9Cr18MoV | Fe | 0.85-0.95 | 17.00-19.00 | 0 | 0 | 0.8 | 1.00-1.30 | 0.6 | 0 | 0 | 0.04 | 0.8 | 0.03 | 0 | 0.07-0.12 |

| • Artisan Cutlery AR-RPM9 | Fe | 0.9 | 18 | 0.3 | 0 | 0.45 | 1 | 0.00-0.40 | 0 | 0 | ? | 0.20-0.80 | ? | 0 | 0.1 |

| • AISI 440B | Fe | 0.75-0.95 | 16.00-18.00 | 0 | 0 | 1 | 0.75 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| AISI 440C | Fe | 0.95-1.20 | 16.00-18.00 | 0 | 0 | 1 | 0.75 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • Aichi AUS 10A | Fe | 0.95-1.10 | 13.00-14.50 | 0 | 0 | 0.5 | 0.10-0.30 | 0.49 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.25 |

| • Aichi AUS 10 | Fe | 0.95-1.10 | 13.00-14.50 | 0 | 0 | 0.5 | 0.10-0.30 | 0.49 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.25 |

| • CTS BD1 | Fe | 0.9 | 15.75 | 0 | 0 | 0.6 | 0.3 | 0 | 0 | 0 | ? | 0.37 | ? | 0 | 0.1 |

| • 9Cr18 | Fe | 0.90-1.00 | 17.00-19.00 | 0 | 0 | 0.8 | 0 | 0.6 | 0 | 0 | 0.04 | 0.8 | 0.03 | 0 | 0 |

KSN Round-Up: The Mediocre

As I said earlier, because of my reliance on the authoritative KSN blog and its authoritative author, Dr. Larrin Thomas, I have bundled up all the KSN data for these Mediocre blade steels in one view. Here you can see how the compromises in the 3 key properties of blade steel play out in these lower grade metals.

The Mediocre: KSN Round-Up

| Toughness | Edge Retention | Corrosion Resistance | Rockwell Hardness (HRc) | ||||

|---|---|---|---|---|---|---|---|

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft-lbs. @ HRc | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Knife Steel Nerds | PREN/PREW Equations | Knife Steel Nerds |

| 8Cr13MoV | 6 | 16 @ 60 | 3 | 392 @ 61 | 14.41 | 60-64.5 | |

| • Aichi AUS-8 | 6 | 16 @ 60 | 3 | 392 @ 61 | 14.41 | 60-64.5 | |

| • 8Cr14MoV | 6 | 16 @ 60 | 3 | 392 @ 61 | 14.476 | 60-64.5 | |

| • Aichi AUS-8A | 6 | 16 @ 60 | 392 @ 61 | 14.41 | |||

| • 8Cr15MoV | 14.41 | ||||||

| Latrobe Case Tru-Sharp | 9 | 41 @ 57.5 | 2.5 | 8 | 13 | 57.5 | |

| • Latrobe 420HC | 9 | 41 @ 57.5 | 2.5 | 8 | 13 | 57.5 | |

| 9Cr18MoV | 8 @ 59 | 21.795 | |||||

| • Artisan Cutlery AR-RPM9 | 12-8 @ 59 | 21.3 | |||||

| • AISI 440B | 19.475 | ||||||

| AISI 440C | 3.5 | 6-5 @ 58.9-63.5 | 4.5 | 405-455 @ 56-62.9 | 7.5 | 19.475 | 56-63 |

| • Aichi AUS 10A | 14.41 | ||||||

| • Aichi AUS 10 | 14.41 | ||||||

| • CTS BD1 | 16.74 | ||||||

| • 9Cr18 | 18 | ||||||

The Junk: Low End Blade Steels

Ah, here are the dregs of the steel world, the bottom of the barrel, the lowest rung on the ladder, the bottom tier, the lowest of the lows, the z-list, the last resort, the worst of the worst, the top nothing, the last in line for the scraps, the back of the drawer, the bottom of the bag, the end of the line, the worst option, the gum on the bottom of your shoe, the outcasts, the rock bottom, aka the Junk tier of the budget blade steels. You have to laugh because otherwise you’ll cry (if you spend your hard-earned cash on any knives with these steels).

These are all ingot steels, and most of them are stainless steels (there are also 2 versions of carbon steel here). Many of these were the wonder steels of their time back decades ago (in most cases, a great many decades ago!), but today are, like, totally cringe. The newest steel here is nearly 30 years old, and the oldest steel is close to 150 years old. These are definitely the geezers of steel.

And these steels are typically found on only the lowest priced, lowest quality knives. Now some geriatric curmudgeons may argue in favor of some of these, especially the carbon steels, but these same old fogy malcontents are noteworthy because they also endlessly extoll the virtues of wooden fishing poles, NECCO wafers, cylinder phonographs, penny-farthing bicycles, hand-cranked automobile engines, horehound candies, ice boxes, corn cobs in privies, candlestick telephones on party lines, and straight razors with badger-bristle, wet shaving brushes and shave soap-filled mugs. Hold your fire, cranky whitebeards, until I finish making my case for why carbon steels are absolute junk on folding knives. Because they are equals among the Junk stainless steel crap with which they are gathered.

The Junk: Introduction

| Blade Steel Family Types | Quantities =< $99 | Aggregate Total | Type | Class | Process | Manufacturer | Invented | Country |

|---|---|---|---|---|---|---|---|---|

| AISI 440A | 1,386 | 2,653 | Stainless Steel | Ingot | various | 1926 | US | |

| • 7Cr17MoV | 1,183 | Stainless Steel | Ingot | Ahonest Changjiang | Late 1990s | CN | ||

| • 7Cr17 | 46 | Stainless Steel | Ingot | Ahonest Changjiang | Late 1980s | CN | ||

| • Aichi AUS-6 | 38 | Stainless Steel | Ingot | Aichi | 1968 | JP | ||

| AISI 420 | 885 | 2,130 | Stainless Steel | Low carbon | Ingot | various | 1915 | US |

| • 3Cr13 | 556 | Stainless Steel | Low carbon | Ingot | Ahonest Changjiang | Early 1980s | CN | |

| • 420J2 | 400 | Stainless Steel | Ingot | various | 1912 | US | ||

| • 3Cr13MoV | 267 | Stainless Steel | Low carbon | Ingot | Ahonest Changjiang | Late 1990s | CN | |

| • Aichi AUS-4 | 13 | Stainless Steel | Ingot | Aichi | 1968 | JP | ||

| • 2Cr13 | 6 | Stainless Steel | Low carbon | Ingot | Ahonest Changjiang | Late 1970s | CN | |

| • 420J | 3 | Stainless Steel | Low carbon | Ingot | various | 1912 | JP | |

| 1.411 | 460 | 1,081 | Stainless Steel | Ingot | Thyssen-Krupp | 1912 | DE | |

| • 1.4116 | 421 | Stainless Steel | Ingot | Thyssen-Krupp | 1950s | DE | ||

| • 5Cr15MoV | 116 | Stainless Steel | Ingot | Ahonest Changjiang | Mid 1990s | CN | ||

| • X55CrMo14 | 78 | Stainless Steel | Ingot | Thyssen-Krupp | Late 1960s | DE | ||

| • X50CrMoV15 | 6 | Stainless Steel | Ingot | Thyssen-Krupp | Late 1950s | DE | ||

| 1095 | 728 | 740 | Low Alloy Carbon Steel | High carbon | Ingot | various | Late 1800s | DE |

| • XC90 | 12 | Low Alloy Carbon Steel | High carbon | Ingot | Early 1900s | DE |

Luckily, the Junk category is the smallest group in the budget blade inventory round-up. The total number of budget knife steels being classified in the Junk category is less than half that of the Decent category. This means you have a lot of better choices for your next budget pocketknife. If you can afford to spend a smidge more than $10 on a budget knife, you absolutely should explore better steels. And one last thought: when you go to the gas station and see something shiny and “cool” inside that glass counter, just know that if the blade does not display a steel type blade marking, it’s using some of these Junk steels and the manufacturer is too embarrassed to label it. Alternatively, if you see a $15 knife with a blade marking of S35VN (or maybe “s35nv”, perhaps even “manga-cut”! Oh those cheeky, crap knifemakers!), the marking is a lie. Ain’t no way. Bottom line: Never shop for a real knife at a gas station, and don’t buy gas at a cutlery shop.

You’ll notice there are not many steel reviews in the Junk category tables, and it’s not only just KSN. It’s everyone. No one really cares about the Junk steels, so they don’t review them, so the ratings data is very hard to come by. This was the main impetus for me gathering similar steels into family groups. Usually there is at least 1 (in most cases) within a family group with ratings data, and that the other steels there will be very similar.

Toughness: The Junk

We now understand that toughness (resistance to chipping and cracking) is an important property of steel. But the mostly low toughness ratings here indicate that these blade steels are very likely to chip at the edge, or even just crack and break under stress. If you buy a low toughness blade, you should also buy a new set of steel sharpening equipment and supplies. The blade edge will probably chip just by simply using it (sometimes just be looking at it with a side-eye!), and a chippy, ragged edge is definitely not the same thing as a serrated edge. You’ll either become a sharpening expert or you won’t be cutting anything for very long.

The Junk: Toughness

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft-lbs. @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI 440A | 3.5 | 4 | 6 | 8 | 4 | ||

| • 7Cr17MoV | 6 | ||||||

| • 7Cr17 | 3.5 | ||||||

| • Aichi AUS-6 | 8 | 9 | |||||

| AISI 420 | 9 | 41 @ 57.5 | 10 | 8 | 10 | ||

| • 3Cr13 | |||||||

| • 420J2 | |||||||

| • 3Cr13MoV | |||||||

| • Aichi AUS-4 | |||||||

| • 2Cr13 | |||||||

| • 420J | |||||||

| 1.411 | |||||||

| • 1.4116 | 2.5 | 7.5 @ 57.25 | 6 | ||||

| • 5Cr15MoV | 6 | ||||||

| • X55CrMo14 | |||||||

| • X50CrMoV15 | |||||||

| 1095 | 4.5 | 11-6 @ 57.5-62.5 | 5 | 8 | 9 | 5 | |

| • XC90 |

Almost all the knife blade steels with toughness ratings in the Junk category are terrible; most are as brittle as potato chips. Which brings me to introducing Chippy the Brittle Blade. He’s pretty embarrassed to be here, but it is what it is.

The single exception, 420 steel, earns a very impressive toughness score, meaning it won’t be a chippy, crispy, crumbly, frangible steel. But like up above in the Mediocre category, don’t get too excited just yet about 420. Here’s a hint: 420 is in the Junk category for a good reason. You’ll see soon enough. And to be honest, I’d prefer a bag of crispy Kettle chips to this 420 Junk.

Edge Retention: The Junk

Well, here we finally have a strong level of uniformity within the Junk category, as they are all uniformly crappy in holding any sort of an edge. Remember I warned you about being too excited at the toughness rating of 420? This is why. 420 has terrible edge retention. Your new tough 420 blade steel knife won’t chip, but it will go extremely dull in no time flat. Just waive this blade steel above a double-walled cardboard box and the edge automatically rolls over in fear. As will all the others here. Dull as ditchwater. Dull as bowling balls. Dull as watching paint dry. Dull as watching grass grow. Dull as feeding your pet rock. Dull as reading and comparing the ingredients in dozens of bags of flour. I’m saying it’s pretty damn dull.

The Junk: Edge Retention

| Blade Steel Family Types | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI 440A | 3.5 | 4 | 1 | 3 | 4 | ||

| • 7Cr17MoV | 1 | ||||||

| • 7Cr17 | |||||||

| • Aichi AUS-6 | 3 | 3 | |||||

| AISI 420 | 2.5 | 320 @ 55 | 3 | 2 | 3 | ||

| • 3Cr13 | |||||||

| • 420J2 | |||||||

| • 3Cr13MoV | |||||||

| • Aichi AUS-4 | |||||||

| • 2Cr13 | |||||||

| • 420J | |||||||

| 1.411 | |||||||

| • 1.4116 | 2.5 | 3 | |||||

| • 5Cr15MoV | 1 | ||||||

| • X55CrMo14 | |||||||

| • X50CrMoV15 | |||||||

| 1095 | 1.5 | 317 @ 61.75 | 2 | 5 | 3 | 2 | |

| • XC90 |

All these blades have between very low to utterly crappy edge retention ratings. This is why we’ve invited Cullen the Dull Blade to join us once again, as this is his true home in the budget blade world. If you squint really hard, it almost looks like he is smiling. Almost.

All these blades quickly become as dull as the dullest dullard from Dullsville next to Dulles Airport. This is especially true for 1095 carbon steel! 1.5? Are you kidding me? The other carbon steel, XC90, is the carbon blade steel in Opinel knives. You know, the wooden banana handle knife with a sheet metal-thin carbon steel blade and a tinfoil locking ring. Yeah, that one. Supposedly it is reputed to have decent toughness (it is rumored to be quite a bit better than 1095, but I could not find an authoritative source on that, so pshaw!), but equally poor edge retention with 1095. This is so dull that even I am getting bored.

Corrosion Resistance: The Junk

Well, we finally have the classic battle royale between stainless steel and carbon steel. These low-end stainless steels achieved a reasonable enough corrosion resistance to pitting (thus why the PREN score is listed). But carbon steel? Er, not so much.

The Junk: Corrosion Resistance

| Blade Steel Family Types | Knife Steel Nerds | PREN/PREW Equations | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|---|

| AISI 440A | 8.6 | 19.48 | 9 | 6 | 5.5 | 9 | |

| • 7Cr17MoV | 19.48 | 6 | |||||

| • 7Cr17 | 19.48 | ||||||

| • Aichi AUS-6 | 7.7 | 13.75 | 5.5 | 5 | |||

| AISI 420 | 7.9 | 13 | 8 | 7 | 8 | ||

| • 3Cr13 | 13 | ||||||

| • 420J2 | 13 | ||||||

| • 3Cr13MoV | 14.98 | ||||||

| • Aichi AUS-4 | 13.75 | ||||||

| • 2Cr13 | 13.49 | ||||||

| • 420J | 13 | ||||||

| 1.411 | 16.15 | ||||||

| • 1.4116 | 8 | 16.65 | 8 | ||||

| • 5Cr15MoV | 16.73 | 6 | |||||

| • X55CrMo14 | 16.15 | ||||||

| • X50CrMoV15 | 16.65 | ||||||

| 1095 | 0 | 0 | 1 | 4 | 2 | 1 | |

| • XC90 | 0 |

At least almost all the blades in the Junk category can do 1 thing right. They are pretty good in resisting rust and corrosion. This makes Vinnie the Shiny Blade pretty happy.

Almost all the blade steels except for the carbon steels. Clearly everyone agrees that carbon steel is utterly useless shite for resisting rust and corrosion. This is the only place where a blade steel has earned a rating of 0! Zero! Zip! Bupkis! Scratch! Nil! Nix! Nada! Nothing! None! Zilch! Zot! Goose egg! Bagel! Diddly-squat! Nought! Sweet Fanny Adams! And on that note, I introduce you to Rusty the Corroded Blade. He tells me his nickname is sometimes Opi!

Rockwell Hardness: The Junk

These Junk category blade steels typically are not very hard. However, carbon steel, with the potential of a lot of work that usually isn’t done (you know, to save money) can technically be treated to be fairly hard. 1095 has the capability to get up to near 63 HRc, but is usually sold on the low-end range, because… I found a site that reported that the Opinel XC90 blade steel was rated between 57-59, but I don’t know the source of that data, so it’s not official.

The Junk: Rockwell Hardness (HRc)

| Blade Steel Family Types | Knife Steel Nerds | A.G. Russell | Cedric & Ada | HRc Tests | Knife Informer | Knife Know It All | Knife PMI & HRc | Oishya | Pokes | Spyderco Forum | zKnives |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 440A | 55-57 | 56.9 | 57 | 55-57 | 55-57 | ||||||

| • 7Cr17MoV | |||||||||||

| • 7Cr17 | 54-56 | ||||||||||

| • Aichi AUS-6 | 55-57 | 57 | 55-57 | 55-57 | |||||||

| AISI 420 | 55 | 53 | 49-53 | 49-53 | |||||||

| • 3Cr13 | 54-56 | 53.8 | 52-59 | ||||||||

| • 420J2 | 49-53 | ||||||||||

| • 3Cr13MoV | |||||||||||

| • Aichi AUS-4 | 55-57 | 55-57 | 55-57 | ||||||||

| • 2Cr13 | |||||||||||

| • 420J | |||||||||||

| 1.411 | |||||||||||

| • 1.4116 | 57 | 55-57 | 56.37 | 55-57 | 54-56 | ||||||

| • 5Cr15MoV | 55-57 | 56 | 55-57 | 55-57 | 54-56 | ||||||

| • X55CrMo14 | |||||||||||

| • X50CrMoV15 | 54-55 | 54-56 | |||||||||

| 1095 | 57.3-62.5 | 56-58 | 56.27 | 56.7 | 55 | 56-60 | 56-58 | 58-60 | 58-65 | ||

| • XC90 |

Ultimately, budget knives using these Junk steels will likely come with Junk HRc ratings. And Prescott the Soft Blade steel is, well, an old softie. He likes candlestick phones, too!

Ease of Sharpening: The Junk

Now here’s where Junk steel will shine – sort of. Actually, no it won’t. As stated earlier, soft steel is actually quite hard to properly sharpen. Instead of repeating myself again, just read the Ease of Sharpening: The Mediocre. Please, do it. Go!

The Junk: Ease of Sharpening

| Blade Steel Family Types | Blade HQ | Blade Reviews (x2) | Cedric & Ada | Just Surviving | Knife Informer | Sportsmans |

|---|---|---|---|---|---|---|

| AISI 440A | 8 | 9 | 10 | 9 | 8 | |

| • 7Cr17MoV | 9 | |||||

| • 7Cr17 | ||||||

| • Aichi AUS-6 | 10 | 9 | 9 | |||

| AISI 420 | 9 | 9 | 9 | |||

| • 3Cr13 | ||||||

| • 420J2 | ||||||

| • 3Cr13MoV | ||||||

| • Aichi AUS-4 | ||||||

| • 2Cr13 | ||||||

| • 420J | ||||||

| 1.411 | ||||||

| • 1.4116 | 7 | |||||

| • 5Cr15MoV | 9 | |||||

| • X55CrMo14 | ||||||

| • X50CrMoV15 | ||||||

| 1095 | 10 | 9 | 8 | 8 | 10 | |

| • XC90 |

Eddie the Easy to Sharpen Blade insisted he be here, given the ratings in the table above.

But as we know, soft steel is anything but easy to actually make sharp, and everything here is soft and marshmallow-y, little more than old, crusty Play-Doh. Removing blade material from these soft and squishy blades is so easy that it will almost slough off. But that blasted burr! It won’t leave! Those burr edges will roll over, flop around and perpetually resist removal, and sharpening Junk steel to an actual apex is a ridiculous pain in the patootie to actually get right. Which brings back our old friend, Henry the Hard to Sharpen Blade.

Elemental Composition: The Junk

Here’s what goes into Junk steel. Notice anything? Look at carbon. Except for the carbon steels, in general there isn’t much there. Carbon is important for hardening steel. However, relatively speaking, there’s plenty of phosphorus and sulfur. Unfortunately, those elements are not desired, but instead are considered impurities. There’s no tungsten in any of these knives. That’s also used to harden steel. There’s a ton of chromium in all the stainless steels, but the stainlessness (corrosion resistance) is not much more than mediocre, and with these all being ingot steels, that means the chromium has had time to segregate out and form into only medium-hard chromium carbides. This isn’t terrible, but only iron carbide (cementite) is softer than chromium carbide. There goes the edge retention! There are many other types of carbides used in higher-end steels that provide much better edge retention, such as tungsten carbide (none present), niobium carbide (none present) and vanadium carbide (only a few of the Junk steels have any vanadium, and when they do, the amount is so infinitesimally small as to be inconsequential (premium steels routinely have levels of V ranging between 3-9%). The compositions show everything about why this is Junk steel.

The Junk: Elemental Composition

| Blade Steel Family Types | Base | Carbon (C) % | Chromium (Cr) % | Cobalt (Co) % | Copper (Cu) % | Manganese (Mn) % | Molybdenum (Mo) % | Nickel (Ni) % | Niobium (Nb) % | Nitrogen (N) % | Phosphorus (P) % | Silicon (Si) % | Sulfur (S) % | Tungsten (W) % | Vanadium (V) % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 440A | Fe | 0.65-0.75 | 16.00-18.00 | 0 | 0 | 1 | 0.75 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 7Cr17MoV | Fe | 0.60-0.75 | 16.00-18.00 | 0 | 0 | 1 | 0.75 | 0.6 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 7Cr17 | Fe | 0.60-0.75 | 16.00-18.00 | 0 | 0 | 1 | 0.75 | 0.6 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • Aichi AUS-6 | Fe | 0.55-0.65 | 13.00-14.50 | 0 | 0 | 1 | 0 | 0.49 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.10-0.25 |

| AISI 420 | Fe | 0.15 | 12.00-14.00 | 0 | 0.09 | 1 | 0 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 3Cr13 | Fe | 0.26-0.35 | 12.00-14.00 | 0 | 0 | 1 | 0 | 0.6 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 420J2 | Fe | 0.15-0.36 | 12.00-14.00 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 3Cr13MoV | Fe | 0.26-0.35 | 12.00-14.00 | 0 | 0 | 1 | 0.6 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0.1 |

| • Aichi AUS-4 | Fe | 0.40-0.45 | 13.00-14.50 | 0 | 0 | 1 | 0 | 0.49 | 0 | 0 | ? | ? | 0.03 | 0 | 0 |

| • 2Cr13 | Fe | 0.09-0.15 | 11.50-13.50 | 0 | 0 | 1 | 0.3 | 1 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| • 420J | Fe | 0.15 | 12.00-14.00 | 0 | 0.09 | 1 | 0 | 0 | 0 | 0 | 0.04 | 1 | 0.03 | 0 | 0 |

| 1.411 | Fe | 0.48-0.60 | 13.00-15.00 | 0 | 0 | 1 | 0.50-0.80 | 0 | 0 | 0 | 0.04 | 1 | 0.015 | 0 | 0.00-0.15 |

| • 1.4116 | Fe | 0.45-0.55 | 14.00-15.00 | 0 | 0 | 1 | 0.50-0.80 | 0 | 0 | 0 | 0.00-0.04 | 0.50-1.00 | 0.00-0.015 | 0 | 0.10-0.20 |

| • 5Cr15MoV | Fe | 0.45-0.50 | 14.50-15.00 | 0 | 0 | 0.4 | 0.6 | 0 | 0 | 0 | ? | ? | ? | 0 | 0.1 |

| • X55CrMo14 | Fe | 0.48-0.60 | 13.00-15.00 | 0 | 0 | 1 | 0.50-0.80 | 0 | 0 | 0 | 0.04 | 1 | 0.02 | 0 | 0.00-0.15 |

| • X50CrMoV15 | Fe | 0.45-0.55 | 14.00-15.00 | 0 | 0 | 1 | 0.50-0.80 | 0 | 0 | 0 | 0.00-0.04 | 0.50-1.00 | 0.00-0.015 | 0 | 0.10-0.20 |

| 1095 | Fe | 0.90-1.03 | 0 | 0 | 0 | 0.30-0.50 | 0 | 0 | 0 | 0 | 0.03 | ? | 0.05 | 0 | 0 |

| • XC90 | Fe | 0.80-0.93 | 0 | 0 | 0 | 0.30-0.65 | 0 | 0 | 0 | 0 | 0.03-0.035 | 0.15-0.35 | 0.035-0.05 | 0 | 0 |

Lastly, there is absolutely 0 amount of chromium in the carbon steels. This is why they corrode and rust so fast. Don’t take your eye off your carbon steel blades. One blink and they will be red, oxidized crust-covered slag when you look back!

KSN Round-Up: The Junk

I’ve been presenting the KSN ratings round-ups for the Decent and the Mediocre steels. But for the Junk steels, there’s just so few ratings to show (as I said earlier, who wants to waste time doing analyses on Junk, I mean, besides me)? Nevertheless, for consistency’s sake, I present it here again for the Junk steels. Consider yourselves educated.

The Junk: KSN Round-Up

| Toughness | Edge Retention | Corrosion Resistance | Rockwell Hardness (HRc) | ||||

|---|---|---|---|---|---|---|---|

| Blade Steel Family Types | Knife Steel Nerds | KSN Charpy ft-lbs. @ HRc | Knife Steel Nerds | KSN CATRA TCC (mm) @ HRc | Knife Steel Nerds | PREN/PREW Equations | Knife Steel Nerds |

| AISI 440A | 3.5 | 3.5 | 8.6 | 19.475 | |||

| • 7Cr17MoV | 19.475 | ||||||

| • 7Cr17 | 3.5 | 19.475 | |||||

| • Aichi AUS-6 | 7.7 | 13.75 | |||||

| AISI 420 | 9 | 41 @ 57.5 | 2.5 | 320 @ 55 | 7.9 | 13 | 55 |

| • 3Cr13 | 13 | ||||||

| • 420J2 | 13 | ||||||

| • 3Cr13MoV | 14.98 | ||||||

| • Aichi AUS-4 | 13.75 | ||||||

| • 2Cr13 | 13.49 | ||||||

| • 420J | 13 | ||||||

| 1.411 | 16.145 | ||||||

| • 1.4116 | 2.5 | 7.5 @ 57.25 | 2.5 | 8 | 16.645 | 57 | |

| • 5Cr15MoV | 16.73 | ||||||

| • X55CrMo14 | 16.145 | ||||||

| • X50CrMoV15 | 16.645 | ||||||

| 1095 | 4.5 | 11-6 @ 57.5-62.5 | 1.5 | 317 @ 61.75 | 0 | 0 | 61.75 |

| • XC90 | 0 | ||||||

Overall, while we had some fun here, there’s not a lot to be happy about with Junk steel. It’s not tough, nor does it have good edge retention, nor is it very hard, nor is it easy to sharpen. The problem with these steels are that they use old compositions that have been made obsolete by newer blade steel technologies. It is (mostly) stainless, and yes, it is very cheap, but so is your toupee, and how is that working out for you?

Weird Budget Blade Listings

Well, when I was compiling all the budget blade inventories from our 17 online pocketknife retailer friends, I also discovered that they do more than sell Decent, Mediocre and Junk budget steels. Many sell budget knives with inexplicably odd or uselessly defined blade materials. Take a look at these amazing feats of uselessness that I uncovered.

| Materials | Quantity |

|---|---|

| Stainless | 3,321 |

| 440 | 1,632 |

| Damascus | 727 |

| Carbon Steel | 454 |

| High Carbon | 221 |

| Surgical | 73 |

| Wood | 40 |

| Plastic | 35 |

| Ceramic | 30 |

| San Mai | 14 |

| White Steel | 14 |

| 400 | 10 |

| Unknown | 6 |

| Titanium | 4 |

So let’s review what we really have here:

- Stainless. The smaller number shown here than the original number mentioned in Part 1 comes from my work to try and parse out what was misidentified there. Stainless is a category, not a steel type (a common theme in this list). Stainless can range from as great as MagnaCut to as lowly as 2Cr13. Pro tip: when a knife steel is listed only as “stainless”, it’s not MagnaCut! It’s likely the lowest of the low-end, chromium-laden, carbon-starved soft steel.

- 440 what? That really just means 440 series, be it 440A, 440B or 440C. 440 itself is not a type of steel! And if a 440-type is not specified, it’s all but guaranteed to be the low-end product, 440A, which is crap for pocketknife blade steel. FAIL.

- So do you know what Damascus means in terms of being a blade steel type? It means nothing. Damascus is not a type of steel, at least in modern Damascus. It’s the name of a process for forging two or more steel types together to create a pattern-welded steel design. The component steels may be nicer, high-end particle metallurgy steels, such as PMC-27 & RWL-34, as used in Damasteel, or it can be the combination of 2 low-end steels to produce a pattern-welded, low-end composite steel that might look pretty. Maybe. But Damasteel will be listed as Damasteel, and is actually a pretty good functional blade steel (if you’d ever want to pay the multi-hundred-dollar premium for it only to scratch and scrape up that gorgeous blade!). The other Damascus crap, well, it’s the metallurgical equivalent of the “mystery meat” you ate in your old elementary school hot lunches. For the most part, modern Damascus is more of an aesthetic issue, not a steel type. The real problem here is that the component steels are rarely if ever identified, which usually indicates that the finished Damascus is not a quality product in terms of use potential. The result of that coagulated, loosely mixed lump of slag will often be a soft steel of an unknown composition combined with another unknown, squishy soft steel. Such a Damascus knife will never be more than a show knife than a real, EDC knife. FAIL.

- Carbon and high-carbon Which one? Hey sellers, these are very broad categories of steel, not specific varieties of steel. Don’t be lazy; give us the deets. And for buyers, such pocketknives will likely have the lowest end steel types in these broad categories. And best yet, they are guaranteed to quickly “patina” (the nouveau synonym for rust). FAIL.

- More accurately known as cheap, crap steel. And “surgical” is not a type of steel, either, but again a category name, albeit one for junk as it pertains to pocketknives. This product is simply a marketing gimmick. It plays upon the connotation that scalpels are incredibly sharp, which is true. But what people fail to remember is that surgical scalpels are thrown away when done (rather than being sterilized in an autoclave like most other surgical instruments). Sometimes scalpels are replaced multiple times during surgery. You know why? Because they do not stay sharp! FAIL.

- Wood and Really. I literally found 40 listings for wood and 35 more for plastic blades in my searches for budget folding pocketknives. I guess you can get a budget, pocket letter opener with this stuff. FAIL.

- Ceramic. I was unaware that there are ceramic folding pocketknives. Apparently, there are. Talk about having a negative number toughness rating! Ceramic blades is notorious for their chippy brittleness, and unless you really want to try to carefully repair the chipped blade edges and resharpen your ceramic blade on super fine, bonded diamond plates, these blades really are not what you want on your next budget pocketknife. It’s just crazy pants.

- San Mai. Do you know what San Mai means in terms of being a blade steel type? Like Damascus, it means nothing. San Mai is a steel sandwich. It’s the Oreo cookie of knife steels, but not nearly as good. It’s typically an unidentified, hardened, (probably low-end) carbon steel core that is sandwiched between 2 layers of unidentified, very low-end stainless steel. Often, it’s presented in the aesthetic form of Damascus (itself a meaningless designation for steel types), but not always. San Mai blades are made to give the carbon steel core better corrosion resistance. But it’s not inherently special.

- White Steel. Which one? Like 440, there are several types of white steel. This is not a type of steel, but a category. And white steel is an extremely low-alloy, high-carbon steel with hardly any other elements in it (aside from a bit of manganese and generous levels of steel impurities phosphorus and sulfur). It is mostly a culinary knife steel, so why would anyone want a folding pocketknife with white steel?

- Which one?!? Sheesh, that’s even worse than 440! 400 is not a type of steel, either, but a larger umbrella category of steels that includes 420, 440, and more. An actual blade steel using this label is likely a very old variety, unusably soft and not worth your time or money. FAIL.

- This is another bit of a marketing gimmick like surgical steel. Pocketknife users always hear such excitement about the use of titanium on pocketknives. However, Ti is usually used on knife scales, backspacers, pocket clips or other handle accessories. In these listings, the blade itself is Ti. That sounds kind of cool, doesn’t it? But seriously, there’s a reason why you don’t see this very often. Titanium is significantly softer than steel. Pure Ti is insanely soft on the HRc scale (HRc 20-30). There are Ti alloys, but these are not much better. Ti-6Al-4V is rated at 33-36 HRc. Ti-6Al-6V-2Sn comes in between 36-38 HRc. Beta titanium alloys, the hardest Ti can get, is still, at best, a lowly 40 HRc. To be blunt, this really sucks! You’d be better off with a folding butter knife. Ti blades make the above Junk steel blades look awesome! FAIL.

- My favorite listing, though, is Unknown. Seriously retailers, you’re not even trying if you list a knife on your website with a blade material classified as Unknown. WHY? FAIL!

I assume that some of the above listings can likely be attributed to one or more of the following problems:

- The manufacturer didn’t give the online retailer enough information.

- The online retailer was too lazy to enter all the information they got from their suppliers.

- The online retailer didn’t review and correct their listings before they were published.

- The online retailer has crappy suppliers.

No doubt the reason is a combination of a few of the above scenarios. But none of this has to be accepted. I protest!!

Unexpected Budget Blade Listings

After going through all the weird listings I found in my budget knife blade inventory round-up, I also found a few impressive listings. The following blade steels are commonly regarded as either premium or ultra-premium.

| Materials | Quantity |

|---|---|

| Crucible CPM S35VN | 476 |

| Bohler M390 | 206 |

| Crucible CPM S45VN | 186 |

| Crucible CPM 20CV | 141 |

| Crucible CPM MagnaCut | 77 |

| Carpenter CTS XHP | 38 |

| Bohler M390MK | 26 |

| Crucible CPM S90V | 19 |

| Bohler Elmax | 19 |

| Crucible CPM CRU-WEAR | 18 |

| Crucible CPM M4 | 14 |

| Crucible CPM S110V | 10 |

| Crucible CTS Maxamet | 9 |

| Carpenter CTS 204P | 8 |

| Damasteel | 8 |

| Hitachi ZDP 189 | 7 |

| Bohler M398 | 3 |

| Crucible CPM Rex 121 | 3 |

So how are these steels found in the budget steel round-up? Well, in some cases, I think these are either data entry mistakes, site search errors, or bait & switch tricks. For example, when I traced down the MagnaCut steel listings I collected, those were either knives offered at $0 (because they were not yet available and thus had no price, and the website’s filter still fed me that inventory) or the blades were absurdly tiny! Like ½” or something ridiculous like that. There were a few little novelty knives with super small blades. Sure, it was technically a MagnaCut blade, but not enough of it to be interesting – or usable. After finding these issues with MagnaCut, I stopped tracking down these crap listings. You are free to do so on your own. Who knows? Maybe there’s a good deal out there after all! LOLOLOLOLOL!

Knife Karen Nitpicks

This has been a long, detailed exploration of commonly available budget steels. Did you notice all the odd things I found? No? Well, I will need to speak the manager. Right now!

- Many online knife retailers include garbage data in their knife listings. Some ridiculous blade materials listings include such indeterminate steel types as ”carbon steel”, “surgical steel”, “400 steel”, “Damascus” (without listing the component steels), even “unknown” (!), but by far, the worst (and most common) is just “stainless”. Incredibly, some of the biggest online retailers are the worst offenders in this space, and shockingly large percentages of their entire inventories are listed simply as generic stainless. How useless!

- Knifemakers, why are you still assembling new folding pocketknives using Junk steels such as 2Cr13, AUS 4, 420J, and several others listed above? Unless you are trying to sell $5 knives, drop that obsolete, crap steel and at least move up to the Mediocre steels (see the section above). Stop selling that garbage!

- Knifemakers, also stop making pocketknives out of crappy carbon steel! Thick, fixed blades knives, machetes, and the like are reasonable use cases for carbon steels, but carbon steel is an ancient steel type. Time has immensely advanced blade steel technology. Cheap, instantly rusty carbon steel has no place on modern, folding knives anymore. Wake up, folks. It’s no longer 1950 anymore. Even Ozzie & Harriet think you are being ridiculous. Do better!

Verdict

Let’s be honest. The quality of knifemaker craftmanship, the variety of knife designs, the variety of steels, blade shapes, grinds and finishes, the number of innovative locking mechanisms, the shapes and types of handle materials, and the quantity of budget pocketknives available today is astounding. It’s better than it’s ever been. Those of us in the pocketknife community are incredibly lucky to be here to see it all. If anything, the overwhelming plethora of choices can befuddle the most dedicated shopper. What do you get? How much to spend? What is a good blade to buy?

But there is a maxim in the world that applies here. No matter how much is available today, we always want more. We still want better, shinier, harder, tougher, sharper, cooler knives. It doesn’t matter that the budget knife blades of today were the super-steel blades of the past – albeit the distant past! But because it was in the past, and the incredible technological progress made in the steel industry since that time, today we have before us innumerable newer and better options, and those old-timer, geezer steels of yore have lost all their former appeal. When you can get a knife blade that will be both very tough and really resist rust for under $100, how much does it matter that it will need to be sharpened fairly frequently? What if you are looking for a budget knife with high edge retention and toughness but are willing to sacrifice rust resistance? Well, that’s now an option, too. Those old blade steels of the past simply can’t compete.

Of course, there is a big market for budget knives, especially good quality budget knives, which is why I conducted this extensive review of the budget blade market. I visited 40 online knife retailers. I limited my search to folding pocketknives that were priced under $100 (hey, that’s now budget! Blame inflation!). I searched for useful inventory information from these retailers and ultimately could gather budget blade steel inventory data from only 17 of them (the websites for the 23 others were either useless, could not be filtered for price and/or blade materials, or had pathetically tiny inventories). Still, from 17 websites, I gathered data for 43,101 blade steel listings comprised of 185 blade material types. Whoa!

From that, I identified the largest inventory “families” of very similar budget blade types. I collected knife steel ratings data for the primary blade steel properties, including toughness, edge retention, and corrosion resistance from popular websites, and parsed the inventory into either the Decent, Mediocre, or Junk categories based on various factors. I also collected HRc hardness data, ease of sharpening data, and elemental blade steel composition percentages (yes, I am a knife steel metallurgy nerd). Admittedly, I read a lot of information on KnifeSteelNerds.com (thanks for the ongoing education, Larrin!)

In this specific post, I did a deep-dive analysis the 2 lower grade blade steel categories. It was fun, generated a ton of fun snark, but also showed us that what was once considered good steel is now righty regarded as bull pucky. Meadow muffin. Cat roca. Cow pie. Night soil. Fetid feculence. Solid waste. Hershey squirts. Baptizing a Baby Ruth. Laying a stink pickle. Yeah, I think I’ve made my point. If you need examples, go back and read the damn post! In fact, read all 3!

This project was a lot of work, and I learned a ton from putting together these articles. The research done here provides an expanse of comparative data on the most common blade steels sold in the budget class of pocketknives. It’s a crazy long series of posts, but I setup the left nav tables of contents to enable you to browse the posts and find what you want to see. Based on the data found here, you’ll be able to make more informed decisions on which budget blade steels will work best for your intended use, as well as which steels you should rightly avoid.

Verdict? You can buy a good knife with a decent blade steel for a budget price. You don’t need to pay Benchmade prices for a good knife, and you can do so much better for your money than buying a garbage knife at the local gas station. Take a look-see and maybe you’ll be better prepared for getting a solid quality knife with your holiday cash (and with the holidays between Black Friday and New Years, you can either save more money or get a slightly higher end knife for your money!) Either way, that sounds pretty good to me!

And as usual for me, The Knife Karen, I had to throw in just a bit of fun snark for good measure. I don’t want these posts to be boring, after all. Enjoy! ![]()