Greetings to thee, gentle reader mine. I bear tidings of a tale so wondrous and grand that it shall cast into doubt the very certainty of thy senses. Attend now as I unfold before thee an illustrious chronicle of the magnificent Excalibur, most peerless marvel of bladesmith’s cunning craft e’er witnessed in all the realms.

Perchance thou dost inquire: is this that same Excalibur, bound in stone from ancient days of Arthur, noble knights, and damsels fair? Nay, I speak plainly—this is not the storied blade of eld. Rather, it is a new-forg’d wonder, wrought with unmatched skill by artisans of surpassing talent, known as Kunwu, hailing from lands far-flung beyond tempestuous seas.

Yet, thou might’st ask, from whence doth this modern legend arise? Lo, none other than a magician puissant and bold, whose mastery is of such magnitude that endless seas of parchment yield effortlessly beneath his sable enchantment of this newfound Excalibur. But let thy heart be lightened, for this wizard, mighty though he be, is noble of spirit and sage of counsel, and known both near and far by the name invincible: The Metal Complex.

Now let us delve most deeply into the chronicle of this noble blade, discern its virtues manifold, and weigh with wisdom why its grace and prowess may be deemed peerless through the annals of time.

TL;DR

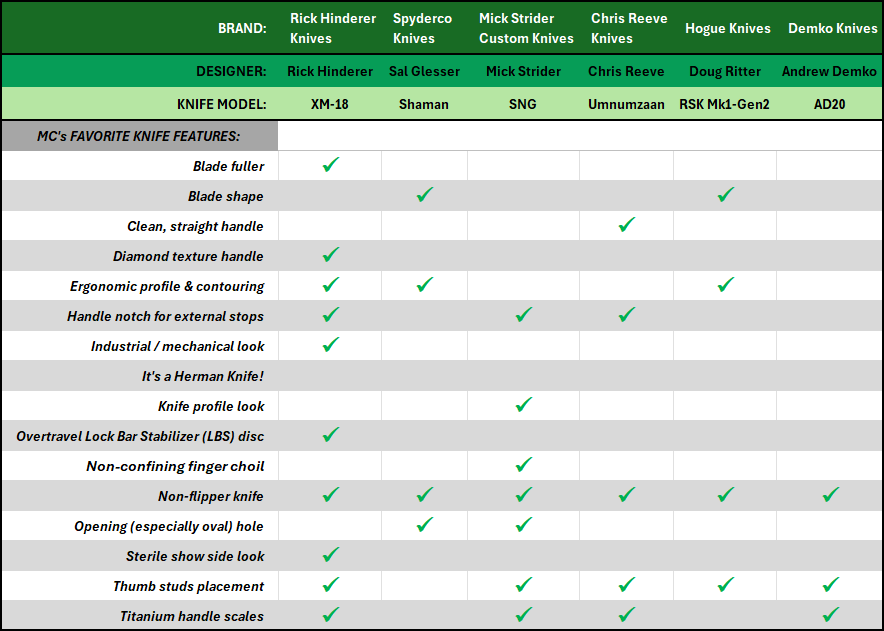

The Kunwu Excalibur is a new titanium integral pocketknife designed by the long-time pocketknife enthusiast and very popular YouTube knife reviewer, Metal Complex. This is his first production knife design. He drew inspiration from elements of several of his favorite, influential knifemakers and their iconic knives, such as Sal Glesser’s Spyderco Shaman, Rick Hinderer’s XM18, Mick Strider’s SNG, Andrew Demko’s AD20, Chris Reeve’s Umnumzaan, and Doug Ritter’s revision of the Benchmade Griptilian with the Ritter Hogue.

To say this simply, the Kunwu Excalibur is a knife designed by a knife reviewer who has handled near-countless knives and presumably knows which design elements can make or break the usability, functionality, and aesthetic beauty of a pocketknife. Let’s explore this knife’s technical specs, examine its features large and small, review its design sensibilities, and assess whether the Kunwu Excalibur proved worthy of the name.

Pros

- Textured, contoured, full-titanium integral handle

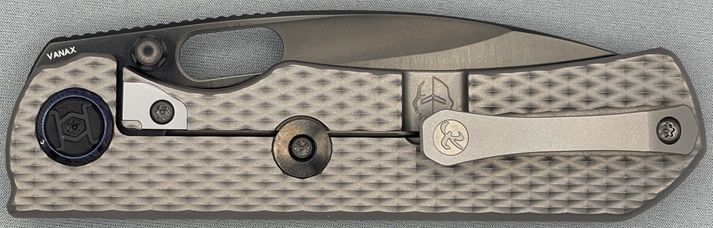

- Lovely, large, very sharp, satin DLC-coated Vanax SuperClean blade

- Very accessible, large ovalized opening hole

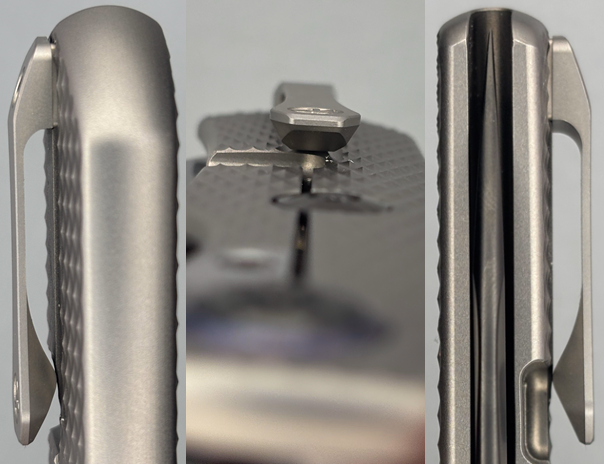

- Milled, comfortable access to frame lockbar

- Voluptuous crowned spine

- Special, little details like the milled logo in the frame lock’s relief cut

- No visible show side fasteners, and all clip side screws are T8

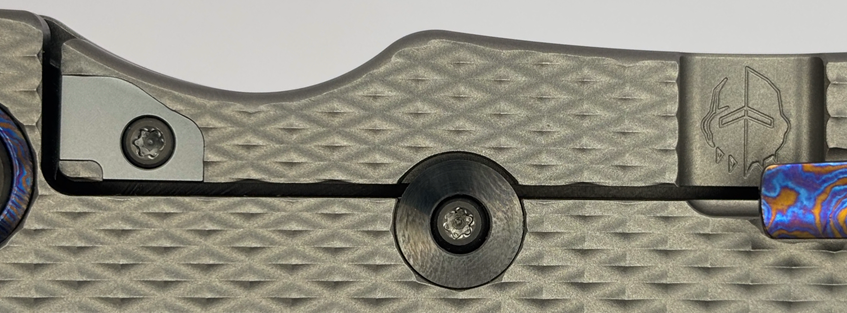

- Milled, D-style captive pivot with Timascus collars on both sides

- True left-handed models (with left-handed frame lock) available

- Thumb studs also serve as external opening stops (braced against cutouts at front of handle

- Center, external overtravel stop lockbar stabilizer (LBS) disc ensures lockbar cannot be compressed downward

- Tight detent makes for snappy opening…

Cons

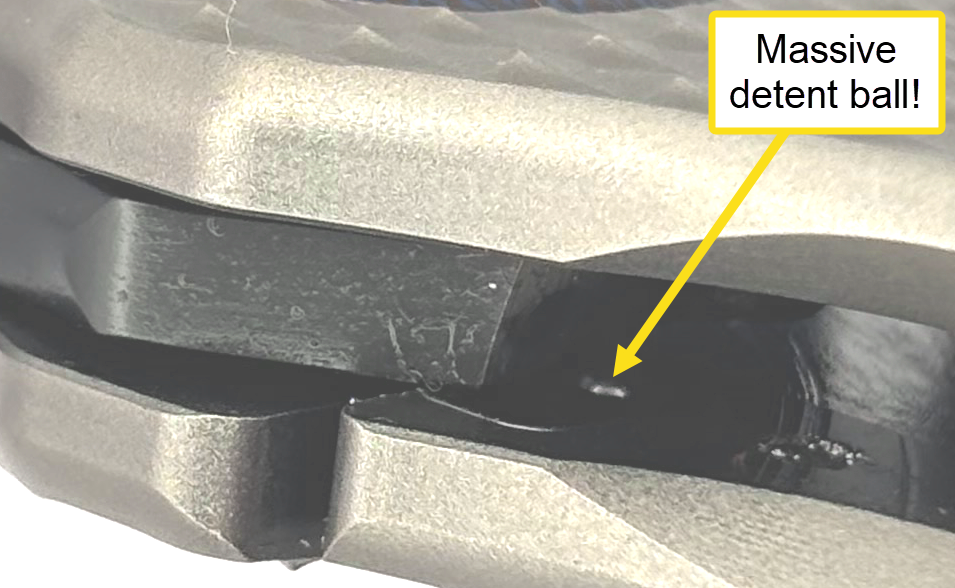

- …as long as the enormous detent ball allows you to actually break through the resistance, otherwise it’s shutty-tight closed!

- Thumb studs are very difficult to use as a result of the above and the steep thumb stud-to-vertical center of handle from pivot

- Handle surface texture looks like a mini version of diamond plate toolboxes for pickup trucks

- Jimping is barely grippy unless you press down hard

- What is that at the top of the blade? Is that a wide fuller? A concave-curved swedge? I’m confused.

- The original titanium pocket clip is a super-tight, pocket-shredding monster

- Another frame lock knife? Ugh.

- Integral handle and sturdy (thick) blade makes for a knife with a big, bodacious booty (or bloated beer belly, depending on your preferred gender stereotype).

Tech Specs

Brand | Kunwu |

Website | |

Manufacturer | Kunwu |

Origin | Yangjiang, Guangdong, China |

Model Reviewed | Excalibur Reverse Tux Integral |

Designer/Design | Metal Complex |

Model Launch Year | 2024 |

Style | Folding knife |

Lock Type | Frame lock |

Opening Type | Manual |

Opening Mechanism(s) | 1. Opening hole 2. Thumb studs |

Pivot Type | Captive, flat, coated, milled, decoratively engraved with Kunwu logo, stainless steel D pivot with 1 T8 fastener with dual Timascus pivot collars |

Pivot Mechanism | Caged ceramic bearings |

Length Closed | 121.41 mm / 4.779" |

Length Opened | 214.70 mm / 8.453" |

Weight | 162.17 g / 5.72 oz. |

Weight-to-Blade-Length Ratio | 1.72 |

Original Packaging | Pearlescent white with a gold logo made of heavy paperboard book style box with a magnetic closure. Inside is a white knife tray insert. |

MSRP & Retail Price | MSRP: $429 |

Edge | Plain | |

Shape | Drop Point | |

Material | Uddeholm Vanax SuperClean | |

Claimed Hardness HRc | 60-61 | |

Blade Length | 94.03 mm / 3.702" | |

Cutting Edge Length | 90.10 mm / 3.547" | |

Primary Bevel Angle | 4° | |

Original Edge Angle | 20° | |

Height | 32.79 mm / 1.291" | |

Thickness | 3.43 mm / 0.135" | |

Main Bevel Edge Thickness | 0.41 mm / 0.016" | |

Thumb Studs Span | 12.74 mm / 0.502" | |

Thumb-Stud-in-Cutting-Path Length | 0 mm / 0" | |

Finish | Satin DLC | |

Features | crowned spine through jimping | |

Grind | High flat grind | |

Swedge | None | |

Fuller | 41.67 mm / 1.641" A rounded, wide, "soft" fuller that maintains the height of the opening hole along the spine until the drop blade’s spine curves down, intersecting through until the fuller runs out. | |

Jimping | 18-cut medium-spaced jimping that are fairly smooth with only modest grippiness. | |

Blade Markings | Show side: None | |

Sharpening Choil | 11.55 mm / 0.455" | |

On-Blade Opening Assists | 1. Long, isosceles trapezoidal opening hole | |

Liner Lock-up on Blade Tang % | 40% | |

Materials | TC4 Titanium (Chinese version of 6AI4V aka Grade 5 Titanium) |

Color | Gray |

Scale Thickness (includes liner) | 3.88 mm / 0.153" |

Scale Texture | Crosscut, diagonal diamonds |

Handle/Scale Features | Bead-blast finish, contoured sides, rounded (crowned) handle spine |

Liner Type | None |

Opening Stop Pin Type | Thumb studs |

Closing Stop Pin Hits Sharpening Choil | No |

Handle Length | 121.41 mm / 4.779" |

Blade-to-Handle Ratio | 0.77 |

Closed Handle Height | 36.42 mm / 1.434" |

Handle Thickness | 12.84 mm / 0.505" |

Pivot Center-to-Thumb Stud Length | 16.27 mm / 0.641" |

Thumb Stud-Angle-from-Pivot at Vertical Center when closed | 46° |

Thumb Stud Tip-to-Scale-Edge Clearance: Show Side / Clip Side | 0.94 mm / 0.037" |

Pivot Center-to-Fulcrum Length on Open Knife | 26.39 mm / 1.039” |

Integral Handle | YES |

Backspacing Type | None |

Lanyard Mount | None |

Pocket Clip | Milled |

Clip Material | Titanium |

Clip Color & Finish | Timascus |

Clip Placement | Non-ambidextrous, tip-up (Kunwu sells a left-handed version) |

Clip Length | 43.65 mm / 1.732" |

Clip Length-to-Handle % | 36.0% |

Clip Features | Milled Timascus clip has a steep ramped toe 3.42 mm / 0.135" wide, resting just behind the external relief cut, and the under-clip scale omits the diamond plate texture. |

Fasteners | None on show side; clip side has pivot, overtravel stop & single pocket clip screws with T8 sockets. |

History of Kunwu

The Kunwu moniker has an interesting provenance, going back in Chinese history to ancient times, appearing in historical writings associated with King Mu of the Zhou Dynasty some 2,900+ years ago. The word Kunwu (昆吾) refers to both a location (likely in the mountains of Henan Province) and the extraordinary quality of locally sourced metal materials used to create the revered Kunwu sword. Legend says the specially forged Kunwu sword steel, known as diamond steel, was so sharp that it could cut jade stone like it was mud. Over time, the name of the Kunwu sword became incorporated into the mythology of both Daoist and Buddhist legends. The mythos of Kunwu encompasses magical metallurgy, weapons of unparalleled strength and quality, and Daoist spiritual symbolism. It’s little wonder that Kunwu Knives sought to be associated with that tradition in Chinese history!

Kunwu Knives, founded in May 2019, had the great misfortune of beginning its business just months before the start of the COVID-19 pandemic. However, they launched their first knife, the Orion, on Kickstarter in early 2020 and had the good fortune to see initial success with their design. They continued with their work, and with each subsequent design release, their good fortune continued as both their audience and reputation grew.

Kunwu as a company consists of a mere 4 people, all with industry experience (~50 years now in aggregate!), with Sergio Badric (the guy who worked most closely with Metal Complex) being their most visible spokesperson. Their goal was to find the folding knife niche that featured high user value in simple, almost utilitarian, designs rather than all anodized flash & dash, with a total focus on details, such as blade heat treats, parts fitment and overall finish work. They hoped that these goals would make them stand out from their local knife-making competitors.

Who is Metal Complex?

I suppose one or two of you, dear readers, may have heard of Metal Complex. He just makes YouTube videos, right? Right. And Neil Armstrong was just a pedestrian on the Moon. Allow me to share what I know about the illustrious knife designer of the Kunwu Excalibur.

Metal Complex, whose real name is, well, I don’t know. The guy is such a public figure in the knife community, yet he does a rock-solid job at concealing his personal identity (I wouldn’t have revealed anything personal about him anyway, even if I knew the information, of course, because he deserves his privacy as much as anyone does; this coming from The Knife Karen of SharperApex!). I had to do a bit of research on the guy, and I will tell you what I learned sourced from the public arena.

Since I don’t know his name, I’ll take the liberty of just calling him MC. He’s a youngster (compared to me!; I remember hearing Abraham Lincoln give a speech when I was a kid!). Even when MC was just a little nipper, he was fascinated by knives. I remember one video where he told the story, when he was just a wee sprout, of him being enthralled by a big (Bowie?) knife hanging on the wall of a relative’s home. He’d stare with fascination at that shiny, sturdy and fascinating blade. His first pocketknife of his own was a Camillus folder received as a gift, but when he got older, his first “real”, adult-style knife he purchased was a Kershaw Blur, sold by Walmart at the crazy expensive price of $57! (Hey, good knives cost good money, right?!) After our wee sprout was all grown up, still so long ago (for him, going back a whole decade or so!), before MC was MC, he worked in sales at an auto dealer, where he was known as that “knife guy”. MC had already been, by that time, a true-blue pocketknife enthusiast, collector, buyer and seller for at least a good 7 years or so before MC was born (are you following this?).

His eponymous YouTube channel was born more than 7 years ago on February 14, 2018, inside a car (a dealership car or his own? We’ll never know! Well, unless he tells us, I suppose). He filmed a video monologue about his first true love (knife-wise, of course), the Hinderer XM-18. And for fun, he also included a Victorinox Swiss Army Knife, both shown on top of the center console lid of that mystery car (my, oh my, how far our young tyke has come! Victorinox? His recent series of videos covering his 23 lb. box of TSA-confiscated knives was littered with Victorinox’s versatile vest-pocket virtuosos, and he was quick to dismiss them and move on to bigger, gaudier, and truly grosser knives).

The MC YouTube channel, like so many other knife reviewers, got off to a slow start. After his first year of doing video reviews, he had acquired the massive tally of 1,000 subscribers! But a mere 6 years later, his channel is the 2nd largest knife community content creator channel on YouTube, having created over 5,100 videos and earning him 724K subscribers (only surpassed by MelissaBackwoods, who began her channel back in September, 2016 and has almost double his subscriber base with 1.34M—you go girl!). After MC’s channel finally took off, he closed his wheeling and dealing car sales career and went full-time as a “media influencer”, a term at which he quickly scoffs at and dismisses, despite his YouTube channel making him one of the wealthiest men in the entire world. Apparently doing reviews of pocketknife designs is a lucrative business (I wouldn’t know)! His early YT influencer/mentors in the world of creating knife video content includes the esteemed Nick Shabazz, Jim Skelton, NuttinFancy, and several others.

MC has his opinions on things he likes and dislikes, and he’s very clear on those matters. For example, he likes loves Hinderer knives, RAM pickup trucks, Monster Energy drinks, saying “sham-in”, overbuilt knives, Winterblade Knives, KU Jayhawks, Timascus and zirconium anything, compression locks, belching, KC Chiefs, mirror-polished DLC-coated blades, sweat pants, Nintendo Super Mario music AND heavy metal music, inexpensive Home Depot tables, integrals, burly metal wristwatches, custom folding knives, milled titanium pens, being the local knife guy with his buddies, bright compact flashlights, Vanax, Herman Knives (me, too!), his family, and talking!

On the other hand, he just hates clones and counterfeit knives, lanyards & fobs, lanyard holes, overpriced knives (cough, cough Benchmade), Dunning-Kruger-Effect loudmouth morons, button plunge locks, Grivory, paragraphs of text printed on blades (cough, ahem Microtech), fixed blades, wood scales, long pocket clips, poo-poo-town blade steels, saying “poo-poo-town”, breaking off the tips of insanely expensive knives, white mustaches, T6 fasteners, slip joints, gas station knives, misplacing his things, PEI (pee-pee) scales, icky dirty grimy gunky hairy stuff, and Opinels. He wisely refuses to allow his channel to become engulfed by divisive discussions about politics, religion and the ever-present, knife community drama. He’s also a consistent supporter of Mollydookers. (Can you tell I’ve watched a few of his videos?)

In his own words, he’s “just a sweaty guy from Kansas” who’s only “tough-lite”, especially when he occasionally indulges in Tabasco shots followed by pickle juice & tequila chasers. He’s also now a professional knife designer. Pretty cool.

Introducing the Kunwu Excalibur

Despite recent popular opinions, the Kunwu Excalibur is not the magical sword from the days of King Arthur and Sir Galahad. It is not the blade that was put into the stone by Merlin the Magician and later pulled from the stone by a young boy who would go on to become King Arthur (nee Pendragon). But neither is it a toy, a mere novelty item, or an overhyped object of grift from an influential and popular knife community celebrity. This is a serious knife, a big knife, an ultra-premium knife, incorporating all the favorite materials and design elements that Metal Complex believes should be part of the perfect knife. He began his knife design plan by compiling the features he liked most from his favorite knives, all of which are part of the most iconic knives today, created by their legendary knife designers.

I listened to a LOT of MC’s Excalibur videos (there are a LOT!) to compile this favorites list, but I believe this could be THE definitive source of knife design features and their inspiration knives used to dream up the Excalibur (unless someone else did a better job on this than me, in which case, whatever). Per MC himself, these are the Excalibur inspiration knives. Let’s take a look:

Now that we can see the knives, the following are his favorite features from those knives from which he stole used for inspiration. Is anything missing?

Let’s get down to the nitty-gritty and see for ourselves what this knife is all about.

Details and Specs

There’s a lot to talk about here, so why are you dawdling around here reading boring text? Move on!

Blade

The Kunwu Excalibur uses Metal Complex’s favorite steel – Uddeholm Vanax SuperClean. BTW, many people also say Vanax or Vanax SC, but the official Uddeholm name is Vanax SuperClean. Now you know. That said, it’s a long name to type, so I’ll use any of the 3 names as I wish, because I’m just like that (my favorite blade steel is CPM MagnaCut – until PM MagnaMax is released, in case anyone asks). While Vanax SC is made by Uddeholm, AB, in the very beautiful country of Sweden, CPM MagnaCut, when it was still being made (!), came from the good ole’ US of A! I’m not sure why MC likes the much lower toughness Vanax compared to the hardier MagnaCut (otherwise they both have near identical edge retention and rust resistance ratings, but Vanax is more expensive!). SMH

I’m guessing MC must be a Suecophile given his apparent devotion to all things Sweden. Maybe he also likes Saabs, IKEA, Volvos, ABBA, and the top Swedish gastronomic delicacies, such as Lutefisk (which smells and tastes like fishy snot) and Surströmming (which smells and tastes like death).

Hmmm. I’ll stick with good ole American sushi, tamales, and adobo, thank you very much.

Blade Features

Vanax SuperClean is very much a beautiful blade steel, and Kunwu takes care to do the heat treat process properly (we presume) in order to optimize the performance of the resulting blade. The Excalibur blade sports a drop point shape, a saber grind, a kooky, blade spine groove, and wears a gorgeous, very fine, satin DLC finish. The finish is stunningly clean. It’s not at all a heavy black coating, especially on the primary bevel. Compared to the heavier black in that kooky spine groove space, the primary bevel looks almost a dark gray, medium-gloss, translucent finish rather than a full black DLC. I’m guessing this appearance is due to the significant polishing done to the pre-coated bevel portion of the blade. Maybe. You can still see the extremely fine vertical grind lines coming through the DLC.

It really is beautiful work and one of the best features of the Excalibur. I’m generally not a fan of coated blades, unless the coating is genuine DLC (and not that chalky, crappy, matte DLC slopped upon Spyderco knives). Kunwu certainly didn’t disappoint here.

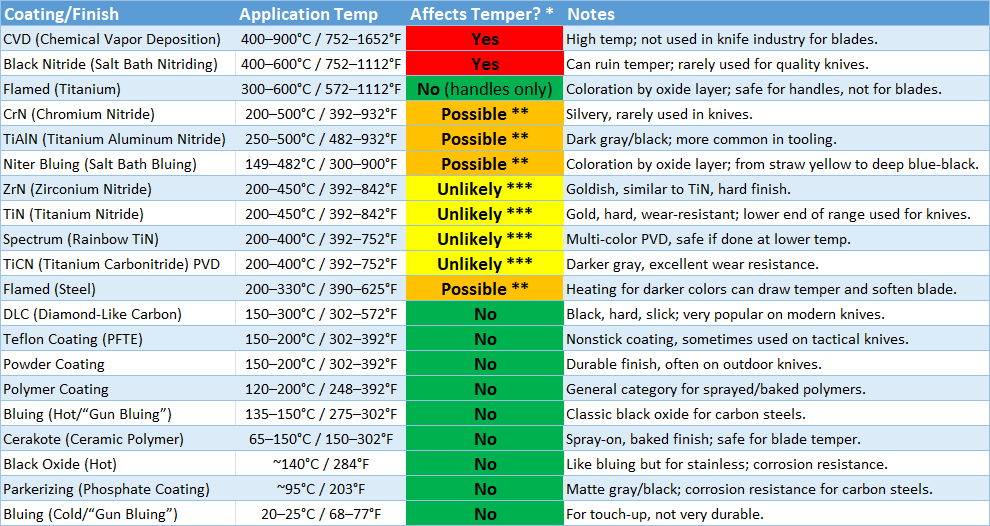

SIDEBAR: Effect of Blade Coatings on Steel

There’s a misleading rumor that repeatedly goes around in the knife community circles that a blade with a coating applied automatically has its HRC rating lowered by 1 point. Pshaw! Many people simply repeat this misinformation without understanding how blade coatings are applied. The truth is that many blade finishes do not affect blade hardness at all. Very few coating types involve significantly high temperatures, and for those that might, good bladesmiths work to keep the coating application process at the lower end of the temperature range. Only a select few of those coatings require enough heat to exceed the bladesmith’s tempering temperatures. Of course, if the heat from the coating application process does exceed the blade’s tempering temperatures, the overheating could actually de-temper (and potentially lower the hardness of) the steel. This is everyone’s big fear, right?

If your current knife blade is coated with one of the materials below, or if you are looking to buy a new knife with a coated blade, take a look at the combination of heating requirements for both the coating types and the blade steel types used, and review the heating temperature ranges used by each. Sometimes it can be pretty clear that the combo of coating type and blade steel used don’t look like a good idea. But as long as the knifemaker did their job correctly (applying the right coating at the right temperature to cause no damage or simply not using a coating that will damage the blade temper), your knife blade’s HRc rating will not be significantly compromised, if at all. Of course, this takes the skill of the bladesmith, the time of the work, and both add up to higher costs. Cheap knives with coated blades will almost always use either cheap coatings (like basic paint) or will cut corners where blade temper will likely be damaged. Keep this in mind when buying cheap, coated knives.

But if the temper was damaged (your blade’s edge retention seems softer than it should be), not only should you reach out to the manufacturer’s support team, you should take that into consideration when planning your next knife purchase. That brand’s inconsistency with bladework quality is a big, red flag about the company’s competence.

* Tempering Data: The data shown here is relative to the most common ranges of blade steel tempering temperatures.

** Possible: Application at the higher end of the temp range may risk temper loss, especially for heat-sensitive steels.

*** Unlikely: Application at the lower end of the temp range (below 250–300°C/482–572°F) is typical for knives and should not affect temper.

Notes:

- Tempering temperature ranges do vary for different types of steel. For example:

- Carbon & low alloy steels are typically tempered in the 177–288°C / 350–550°F range.

- High alloy tool steels are typically tempered in the 149–177°C / 300–350°F range.

- Stainless steels tempering temperatures are more product-grade dependent.

- Lower grades like 440C are commonly tempered in the range of 149–204°C / 300–400°F range.

- High-end steels like S35VN usually are often tempered between 204–538°C / 400–1000°F.

- Some ultra-premium steels like MagnaCut will be tempered between 177–200°C / 350–400°F, but the range can go much higher.

- Additionally, both the high-end and ultra-premium grade steels are often tempered twice, and the duration for each session can go for 2 hours. Of course, YMMV.

- CVD, Salt Bath Nitriding, and flamed can damage blade steel temper.

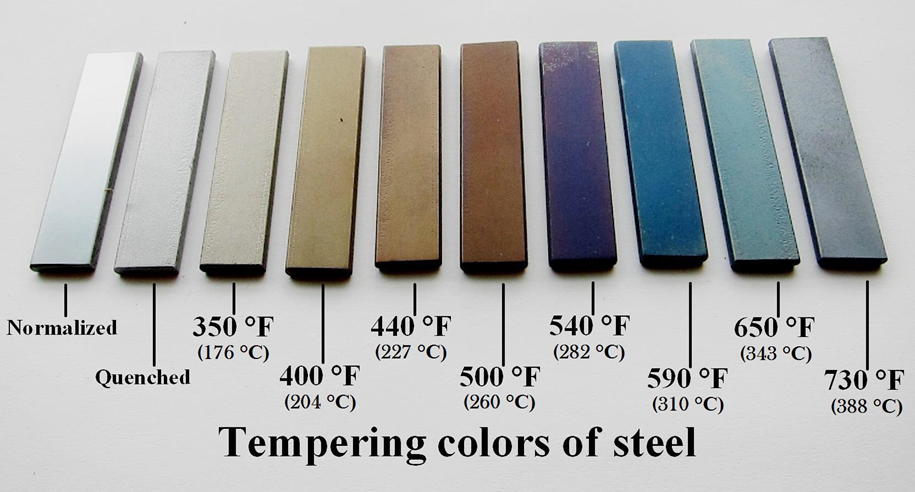

- Flamed finishes are not coatings, per se, but colorizations. The temper-safe range depends on the color applied vs. the original temper temperature.

- PVD (Physical Vapor Deposition) only refers to the coating process. Most blades marked as PVD are coated with TiCN or TiN.

- Most modern PVD-applied coatings (TiCN, TiN, ZrN, & DLC) are temper-safe when properly done.

- Spectrum is just a multi-color PVD finish and temper-safe if properly done.

- Gun Bluing is temper-safe for blades.

- I didn’t even mention paint, because, well, it’s a room temperature coating and it’s poo-poo-town.

Knowing the temperature at which a blade steel was tempered is crucial for not damaging the blade steel’s hardness. A coating applied at 250°C might be fine for a steel tempered at 300°C, but it certainly could damage a steel tempered at 250°C. Another factor at play is the duration at which the temperature used to apply the coating is held. Briefly reaching a high temperature vs. sustaining a high temperature over time will have different results. For once in your life, you can say that shorter is better!

Unfortunately, knife manufacturers never reveal the temperature at which they do their tempering (it’s part of their proprietary, bladesmithing secret sauce, don’cha know). The data is also way too geeky, and it would only be of interest to a small number of people (and you’d need even more contextual heat treat data for it to make sense, anyway). Ultimately, the point is moot as extremely few people would / could apply new coatings to the knives they already have. As such, despite us blade steel geeks being interested in knowing this, we are left with no choice but to trust the knifemakers to do it right, as they are the ones applying these coatings to their own blades. After all, they should know how to apply the coatings correctly, right?! Right?

Lastly, I wanted to address why Flamed (Steel) in the table above has a range with a lower starting temperature but has a higher caution associated with it. Most of the time bladesmiths will know how to work within the lower coating application temperature ranges to preserve the steel’s temper. Some lesser-experienced and lower-cost blade makers won’t have the means to apply some quality coatings but will be interested in applying oxidizing colorings based on heat exposure. In those cases, depending on the color desired, flamed steel colorization can get much too hot, and thereby de-temper the steel. IN this case, color = heat, so the resulting spectrum color can be a nice visual feature or a blade steel-softening exercise that is ruinous to the final product.

As a serious aside, if you buy a knife and see the blade edge has a yellowish (or darker) hue on it, that likely means that the manufacturer did a crackerjack, crap job in sharpening the final edge on a fast grinding wheel, and that section of the blade got too hot, thereby damaging the edge. Unless you want to try to reprofile the blade and remove the steel through the damaged section, return it, and be vigilant if you opt to buy another knife from that maker, as their quality control is highly suss.

Sidebar complete – now back to our regularly scheduled program.

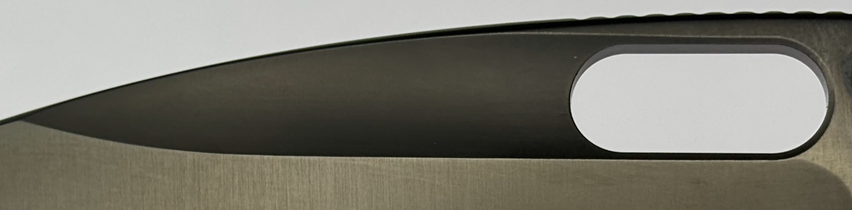

Kooky Grooves

The grind line between the primary bevel and the kooky groove is nicely milled with a clean, clear and crisp edge. So let’s talk for a moment about that kooky groove. It’s a region that actually begins at the back end of the stadium-style oval opening hole (which measures 18.49 mm / 0.728” wide and 7.80 mm / 0.308” tall), after which a wide, rounded, shallow sort of groove region that’s the same height of the opening hole and continues straight along that oval hole’s angle line. That groove region runs barely beneath the blade spine line until the blade’s drop point curves the spine downward, where the groove then intersects into the spine edge, which thins out the spine edge as it runs along, until the straight groove region finally runs out on the down-turning spine.

So what is that kooky groove region called? Perhaps I am a moron (and that would be the 3rd time in the last 45 years I was accused of that), but when I first saw it, I wasn’t sure if it was a funky fuller or a strange swedge. It’s sort of like an open culvert on a knife blade, or a blood groove of titanic proportions. I ended up needing to once again go watch those MC Excalibur videos to discover that he calls that groovy area a fuller. While I poke fun at it, I think it is an unusual and attractive design feature that I have not encountered before. Cool, man, I dig it.

Opening Mechanisms

The blade is equipped with 2 opening features.

The first is the aforementioned opening hole (a stadium oval, if you will). The interior edges of the oval are supposed to have been chamfered, but that’s not actually the case. The opening hole is placed just inside the kooky groove, er, I mean the fuller. What I see (and feel) is that the “chamfer” present is the slight, obtuse angle of that wide fuller compared to the spine. Once that fuller angle starts, the opening hole cut starts, and that is a straight, 90° cut perpendicular to the spine. So what passes as a chamfer is simply the obtuse angle difference between the fuller’s rounded groove and the hole cut. It’s wider than 90°, but the edge is still there.

Perhaps this retained edge is there to offer better traction for the reverse flick fingertip, and to be fair, that works as expected. In fact, the reverse flick is beautifully easy and satisfying to do. That big blade just thumps into place! But those sharp opening oval edges scrape up my fair Knife Karen fingernails with every flick. I guess this is the price I pay to play with big-league knives.

The second blade opening feature is a pair of thumb studs. Now as you may know about me (who am I kidding? no one would know this!), I love me some big ole, studly thumb rocket rods. The physical design of these thumb studs makes them quite comfortable to use when opening the knife (when you can do it). But when I first got this knife (and it’s a borrowed knife because someone who shall not be named did not respond to my several requests to write up this review), I could not open the blade with these studs. I knew these “studs” are used as a pair of external opening stops, and given it was impossible for me to even budge the blade doing the same motion I do on every other thumb studded knife I have ever used, I figured these little, perpendicular steel outcroppings were the same feature used on the Strider SMF/SNG knives: non-thumb stud, opening blade stops. So I once again went back and watched those many MC Excalibur videos only to watch him slam that super-duper-grouper-trooper, detent-locked blade against those open stop pins like a pro using those same little rocket rods. I was stunned!

Well, I finally figured it out. It could be, in part, that the detent is starting to slightly lighten up (maybe; it was brand new when I borrowed it). But what I found to do was to hold the handle as low as possible so that there is only a little bit of bend in your thumb when touching the stud. Then give a very firm flick up and slightly to the left. BAM! The blade bursts through that monstrous detent and slams its rocket rods into the handle. But watch out for those false starts, where that vicious, inertia-bound detent says, “No Way, Not Today, Popinjay!” (that’s a saying, isn’t it?). Execute too many of those false starts and you will eventually tear up your delicate thumb pad skin! Ouchie!

These thumb stud opening stops, positioned as they are behind the opening hole, do not hinder (see what I did there?) the blade’s cutting path, so this is all very good. In my repeated viewings of the MC Excalibur videos, I also learned that, in the final design revision, internal titanium closing stops were added. Hmmm. Right. I just got a new pair of glasses, and I have a decent enough flashlight, but I swear I can’t see those internal stops. But it does stop in the right position when it’s closed, so I guess they’re in there.

Lastly, enough of the blade’s opening hole is exposed that you can also do a satisfying Spydie Drop if you wish. That’s always fun!

Spine Features

The blade spine area has some very nice features. First off, Kunwu milled a sweet, smooth, sexy-curvy, crowned spine that runs from heel to tip. Oh so nice! The spine also features an extra-long, 18-cut jimping section that goes all the way out to the end of the opening hole, thus making the jimping actually useful! The jimping texture is sort of okay, but not great. If you press your thumb down on it hard, you’ll feel some grippiness. But no other knifemaker has done such pulchritudinous jimping like that on the Viper Moon – another visually stunning knife with divine design features. That jimping is sexy looking, fantastically functional, and ergonomically excellent.

Choil

MC took care to ensure the blade had a very comfortable and multi-functional finger/sharpening choil. That moderately expansive choil, which measures 11.42 mm / 0.450” from the blade handle to the start of the cutting edge (the length of the full choil, which includes the matching choil milling on the handle, spans 18.80 mm / 0.740”), makes the knife very inviting to hold it in a choked-up grip and do more precise work. However, as there is no free lunch, you also lose some of the cutting edge.

One last solid design benefit of the choil is that the plunge grind is well behind the start of the cutting edge, so if you are one of the very few who will use your beautiful, expensive Excalibur knife enough to require several sharpenings, the narrowness of the main bevel ensures you’ll have an easy time and a good result with that sharpener (unless you use one of those horribly crappy, pull-through sharpeners, which does nothing but ruin your blade edge).

Geometry

Regarding the narrow primary bevel, my little goniometer measured the hollow-ground, primary bevel angle at 4°, and the edge angle at 20°. Quite slicey, despite the blade is somewhat thick (3.43 mm / 0.135″) to be a super slicer. MC actually increased the blade thickness from the original 3.18 mm / 0.125″ during the prototype stage to help improve the balance of the knife, and it’ll help support the integrity of the Vanax SC blade against chipping, which only has medium-level toughness. The edge bevel is ground perfectly and symmetrically on both sides of the blade, and I can attest that the blade comes sharper-than-razor-sharp from Kunwu. Very impressive!

Blade Markings

Lastly, the blade markings are largely a non-issue with the Excalibur. On the show side, there is literally nothing. Nada. Zilch. Zip. Bupkis. And on the clip side, well, there is nada. Nil. Nix. Naught. Diddly-squat. That’s exactly what MC says he wants everyone else to do, and he leads by example. I will point out that on the very top back of the clip side of the blade is small white text revealing the blade is made of Vanax. But that reveal is not visible on the opened blade. It’s totally sterile, just the way MC likes it. He says he really likes sterile. Hmmm. Maybe he suffers from mysophobia.

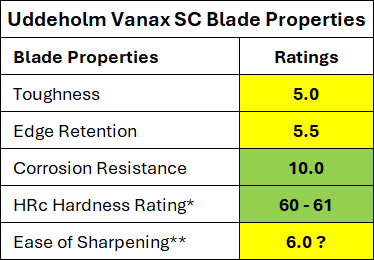

Uddeholm Vanax SuperClean TECHE

When I can get the ratings data for the knife steels I review (I primarily gather the data from the authoritative KnifeSteelNerds.com as available), I include it here in a section I call TECHE. What does TECHE mean? Well, you could look at the table below, but it stands for Toughness, Edge Retention, Corrosion Resistance, HRc Hardness Rating, & Ease of Sharpening. Clever, huh?

Note that all ratings but HRc Hardness Range are based on a scale from 0-10; Hardness is based on the Hardness Rockwell C scale, which technically is between 20 and 68.

* HRc Hardness Rating data was gathered from the Kunwu Crew webpage.

** Ease of Sharpening data is not a rating produced on KSN.

Blade Dimensions

Gather around, children! Let’s talk some blade spec numbers taken by my very own, very large (12”) digital calipers (I’m a stickler for detail). The Excalibur’s lovely DLC-coated Vanax blade is 94.03 mm / 3.702″ long with a cutting edge length of 90.10 mm / 3.547″. The blade’s height is 32.79 mm / 1.291″, the spine is 3.43 mm / 0.135″ thick, while the thickness at the bottom of the primary bevel, just above the blade edge, is 0.41 mm / 0.016″. My calipers also told me that the span of the thumb studs is 12.74 mm / 0.502″ (just a tad shorter than the handle width, which we’ll cover shortly), and that the frame liner lock-up on the blade tag comes in at 40%. Lastly, that kooky, groovy fuller is 41.67 mm / 1.641″ long and the length of the finger/sharpening choil (please don’t attempt any finger sharpening, people) is 11.55 mm / 0.455″.

HRc Rating

According to Kunwu, the Excalibur’s Vanax SC blade comes in at a hardness rating of 60-61 HRc. According to the Uddeholm Vanax SuperClean data sheet, this is the optimum hardness range. Since I don’t have the means to do my own hardness testing, I checked all the online databases I could (Transparent Knives, LuvThemKnives, Cedric& Ada, Knife Steel Attributes), and no one has tested a Vanax SC blade for hardness. Sheesh. We have no choice other than to trust Kunwu, but given their reputation, I’m good with this.

Knife Body & Scales

While the beautiful, drop point, satin DLC-coated, ridiculously sharp, Vanax blade is definitely a key aesthetic element of this knife, the handle is no slouch, either. Let’s take a deeper dive into the MC-designed Excalibur handle.

Handle

As one would expect from a Metal Complex-designed pocket folder, the handle uses Ti-6AI4V (titanium alloyed with 6% aluminum [AI] and 4% vanadium [V]), aka Grade 5 titanium alloy (called TC4 in Chinese manufacturing). Ti is an excellent knife handle material due to its high strength, corrosion resistance, and light weight (not to mention its true cool factor. Titanium, named after the Titans of Greek mythology, giant deities whose rule pre-date Zeus and the gang, whose name is used to describe objects of great size, strength and power. Titanium was also used as the incredibly resilient, heat-resistant skin of the SR-71!).

Fortunately for us, MC took the titanium handle design the extra distance, as the Excalibur sports an integral Ti handle! This integral handle is milled from a solid block of titanium alloy.

Titanium integrals possess both specific benefits and drawbacks, including:

Benefits:

- Fewer parts for maintenance

- Strength & durability

- Modern aesthetics

- Massive cool factor

Drawbacks:

- Tight working space during maintenance

- Significant added cost

- Added weight

Regardless, a Ti integral handle makes for a very special pocketknife.

The Excalibur model I am reviewing is the Reverse Tux model, which besides the satin DLC blade, comes with a gray, bead-blast handle. As you might imagine, there is no milling for weight reduction, other than the milling needed to create the blade channel, the frame lock relief cut, and holes for the pivot and fasteners.

The top of the handle, where one might find a backspacer on regular pocketknives, is full-length crowned and smooth. It’s really nice to the touch. The sides are slightly contoured (an even more premium feature with Ti handles) and come with texturing to provide added grip.

The texturing used by MC seems to be right up his alley. We know that he drives a big-ass pickup truck, so it makes (some) sense that he chose to add to his wondrous DLC-coated Vanax and titanium integral knife a similar looking, mini-version of aluminum diamond plate pickup truck bed toolboxes and step plates. Does that texture improve the grippiness? Sure. Does it visually work? Why not? Does it remind me of the tread texture of industrial stairs, catwalks, work platforms and moving truck ramps? Yeppers, it sure does. Does it matter? Not really, but it’s worth calling out for a laugh, innit?!

Pivot

The pivot is a strong design feature of the Excalibur. Some knife manufacturers appear to not understand the importance of the pivot in knife design. For example, take the aesthetic design of the Spyderco Sage 6, a $400-MSRP knife equipped with a 3” CPM-S90V, non-contoured, peel-ply carbon fiber handles, and a paper clip pocket clip. Aside from the blade steel, nothing truly special, right? But, design-wise, it gets worse. They clearly used a pair of cheap screws from Home Depot for this expensive blade’s pivot (as they do for so many other knives they sell). And as the cherry on top, both sides of the pivot have a Torx socket, implying it’s not even captive! Are they serious?

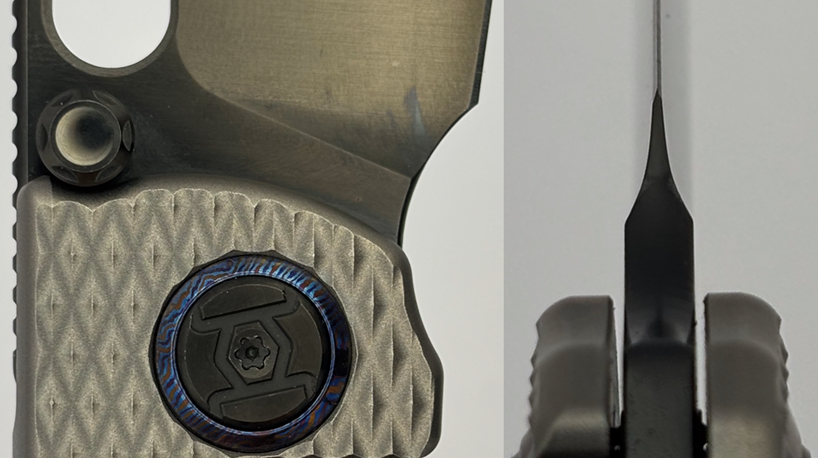

Metal Complex scoffed at this cheap AF design approach to his pivot and instead went big, employing a pair of 9.45 mm / 0.372” large, flat-milled, coated (DLC?), captive steel pivots, both sides milled with the Kunwu pivot logo, and a pair of Timascus pivot collars, with the show side collar being very large and clearly visible. Lovely.

The blade rides on caged ceramic bearings that, once the open knife’s lock bar is released, smoothly glides the blade back into place with only a couple of encouraging, little shakes instead of the wicked-fast drop of a guillotine. It‘s very well designed and executed. And of course, the blade tip is perfectly centered. Kunwu quality!

Locking Mechanism

There is exciting news here! The Kunwu Excalibur is equipped with – get ready! – are you excited yet? – the most modern, most forward-thinking, advanced knife lock design available today! It’s strong, reliable, and easy to use. I am thrilled to announce that Excalibur has the distinct honor to be the very first integral handle production knife using the famous, recently released from patent, top liner lock, also known as the Spyderco Compression lock! Isn’t that awesome?

Wait… I’m getting a call… {answers phone} Hey, it’s Metal Complex himself! Hey, dude! I was just sharing the great news… What? Plans have changed? Then what is it going to be?… Oh, no! Are you serious?… You’ve got to be kidding!… Holy crap! You’re Metal Complex! You’re the knife community’s biggest advocate for compression locks! This can’t be happening! NO!… {whimpering cry, hangs up phone}

Well, folks, I apparently got it wrong. The Excalibur is officially just another bloody titanium frame lock knife. Boo!!!

All seriousness aside, I understand that MC’s Plan A knife lock was in fact supposed to be a compression-style lock. But Kunwu had not yet built a compression lock (it only recently came out of patent protection), and doing their first one inside an integral handle was going to be a daunting task at best. I forgot what Plan B was, but that apparently was a non-starter as well. So MC & Kunwu fell back again, now to Plan C: another, everyday frame lock.

Now that said, it’s a very well-executed frame lock (not nearly as difficult to operate as the one I dealt with in a recent review). It offers plenty of access thanks to strategic carve-outs inside the titanium frame and lockbar. It has plenty of confidence-inspiring blade tang lock up (I roughly measured it to be ~40%), yet also has excellent release. There’s no lock stick, blade play, double-clutch, or any of the faulty “lash” problems (neither pivot nor detent) so many lesser quality knives possess.

This frame lock has redundant overtravel stop protections built in. There’s the typical overtravel frame lock mechanism with the steel lockbar insert on the titanium bar, but MC’s appreciation for the mid-lockbar, Hinderer-style LBS (lock bar stabilizer) disc is replicated here. MC says he likes the industrial / mechanical look of the LBS system, but it also has a useful function. The LBS adds protection against lockbar compression downward into the scale, something the typical overtravel stop doesn’t do.

One of the best things about the Excalibur is, despite the frame lock being a non-ambi blade lock, MC, a big supporter of all our Sinister, Southpaw, Cuddy Wifter, Goofy-Footed, Mollydooker, Katy-handed friends, he insisted that Kunwu also make purely left-handed models. Not just pocket clips, but true left-handed frame locks! Attaboy!

One cool feature is that the external-facing frame lock relief cut (while perhaps not as aesthetically pleasing to some, is just a tad more functionally usable and durable from an engineering standard. Now you know) is not wasted space. Kunwu milled (not laser-etched) the Metal Complex helmet logo into that space! Very impressive! And I am happy to report that the relief cut doesn’t have 90° angles along its sides. Kunwu knows how to build reliable and long-lasting frame locks (even if those locks are boring).

DETENT!

I want to take a moment to talk about detent. As any knife user who has handled a few folding blades that use a detent ball knows, there’s detent and then there’s DETENT! Kunwu uses the latter. I know MC likes his detent balls big and firm, and he certainly got his wish. But this detent is enigmatic to say the least.

First off, I can’t explain why, but doing a reverse flick using the opening hole is shockingly easy! Don’t get me wrong – it’s not soft, but the reverse flick is easily and reliably done. It’s really fun! Using either your index or your middle finger will do; overcoming the detent with this method is pretty easy, and it slams into place with immense satisfaction!

But when it comes to using the thumb studs, this thing is a beast. It feels as if the detent ball is a 6 mm marble! The inertia generated by that monstrous detent ball seems almost impenetrable. As I mentioned earlier, these little rocket rods are incredibly finicky to use.

If you go in thinking you know how to use thumb studs, sure, you might open the knife. Then again, you might shred the tender skin off the top of your thumb print! In my case, when I began using this borrowed knife (more on that later), I could NOT open the Excalibur with its rocket rods. The blade may just as well have been welded shut. The damn thing would not budge! And MC describes this as a medium detent! I tried various angles, amping up the deployment pressure (as much as my tender Knife Karen thumbs could muster), but the knife was unopenable – unless I put my index finger in the opening hole, where the Excalibur bows down to my mastery of the flick.

As Tuco angrily shouted after repeatedly failing to open the Excalibur with the studs, “The detent of the knife is tight, tight, tight! “ Can you tell it pissed him off a little bit?

Yes, it’s that tight, my friends, at least with those rocket rods. Breaking on through to the other side of that hefty detent, once it happens, though, makes opening the knife an explosive experience – assuming you can do it.

Luckily, I finally found a way to consistently open up this recalcitrant rapier. I hold the handle as low as I can, so that there is only the smallest bend in my thumb when touching the stud, then attack that stud with a very stout push up at a 25° angle to the left (and yes, my friends, I am a total metrics nerd, and I measured that thumb-stud-knife-opening angle with a protractor!). BAM! It slams home in an explosive flash. Don’t bother trying a wider angle, though, as that impenetrable inertia of the 6 mm detent ball will make the blade refuse to move. And if your hand is too far up on the handle, it’s way too easy to push at that wider angle.

Now maybe a few of you big, burly dudes with slightly larger than average, baseball-mitt hands may believe it easy, but I think even the mighty-handed Jeff Dabe may struggle a little bit, and that guy is serious business!

Stop Pins

Here we have yet another fun design decision from MC. Those rocket rods (thumb studs) serve double duty as the opening stop pins. Taking inspiration from the Hinderer XM-18, the Strider SNG, and the CRK Umnumzaan, MC opted to use those studs to stop at the front top of the handle. During the prototyping phase, he decided to add a little shouldering indent at the contact spot on the handle because, hey, why not? Initially, the studs were also supposed to serve as the closing stop pins, but the already difficult to use thumb studs were too buried against the handle to make the knife easily openable (as if it is easy now). Additionally, and probably more importantly, when DLC-coated studs hit the DLC-coated handle, the repeated impacts wore off the DLC, leaving an impact mark.

So to prevent the impact marks from showing on the more visible bottom of the handle, the rocket rods were repositioned just a tad away from the handle edges and were replaced with internal titanium stop pins. At least that was MC said in one of his many Excalibur feature videos. Perhaps my recent eyeglasses prescription was a disastrous update, but I spent a LOT of time with several flashlights trying to find those internal pins (I can’t take the knife apart as I borrowed it from a dear friend). So there’s no photos, no identification at all, but I can say that the blade does close correctly, so something is doing that!

Lanyard Mount

The last 3 dudes in the world who care about lanyard fobs, Jordan, Kent, and Owen, are in tears over the fact that the Excalibur has no lanyard mounts available to them. Per MC, there’s no hole, no standoff, no external loop, nothing at all. These guys cried, but the rest of the world rejoiced.

Handle Dimensions

Hey kids, we have more numbers and metrics to cover, so let’s (temporarily) stop the kidding around and get down to business.

The handle length is 121.41 mm / 4.779″, and given the already mentioned blade length of 94.03 mm / 3.702″, the Blade-to-Handle Ratio comes in at 0.77. The closed knife handle height is 6.42 mm / 1.434″, the handle thickness is 12.84 mm / 0.505″, and the thickness of the integral handle’s side walls is 3.88 mm / 0.153″.

The pivot-center-to-thumb-stud distance, where a higher number can mean less leverage for easy, fast opening, is 16.27 mm / 0.641″. The angle of the thumb stud from vertical center at the pivot when closed is 46°, which is the widest angle measurement I’ve taken so far at SharperApex. This wider angle may also be contributing to my difficulty in opening the knife with those little rocket rods. The size of the gap between the closed blade thumb stud and the adjacent handle edge, which when very short, can also add more difficulty with opening the blade with the studs, was a mere 0.94 mm / 0.037″, the smallest gap I have encountered at SharperApex (especially when compared to the incredibly roomy gap on the Arcane Design The Creature). And finally, when open, the distance from the center of the pivot to the knife’s balance point (the fulcrum) comes in at 26.39 mm / 1.039”. One inch! This baby bears a big, beefy butt!

Ergonomics

The design of the Excalibur shows the strong consideration made for ergonomics. The handle is very comfortable to hold, given the wide finger choil, the wider frame lock cutouts, the contouring of the handle, the excellently chamfered handle edges, and the rounded top (back) of the handle. The handle, though, is definitely a hefty, husky, podgy little thang, and we’ll be talking more about that in just a moment. The diamond plate truck toolbox texturing on the handle sides gives you something on which you can get a firm grip. The jimping on the blade spine may not be the jimpiest jimping I have felt, but it’s definitely better than most, and it does extend all the way down the spine length to the end of that stadium-style, ovalized opening hole – a much-appreciated design decision.

The ease with which the user can open the knife is a critical part of the overall usage ergonomics. I loved the ease I felt in doing a reverse flick via the opening hole. Index finger, middle finger, it didn’t matter. The Excalibur was tuned perfectly for that. However, I’m not a big fan of the thumb stud implementation. It’s the only knife I’ve had such difficulty in using the rocket rods to open the knife overall. I did finally figure out the secret (which I discussed earlier), but that means I need to think about what I’m doing instead of just doing it. I suspect calling upon those little studs to pull double duty as opening stop pins forced a compromise on the required location of the studs on the blade.

I will say that opening the knife with the studs now has gotten significantly easier lately. I’m not sure if that is due to the break-in process of the knife, my self-training on how to do it effectively, or a combination of both. But I’m guessing it’s the thumb exercises I recently began doing to get better at this stuff. I can now thumb-press 3 lbs., but only for a few reps before it tuckers out.

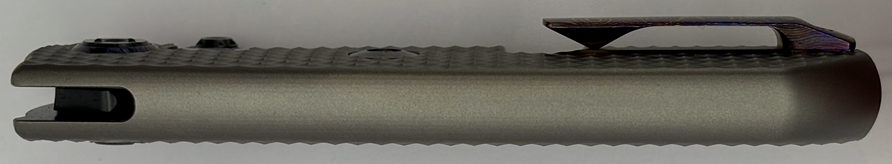

Hardware

Let’s talk about the accessory hardware on the Excalibur. First off, we have that original, milled Timascus pocket clip. It’s definitely a sexy time pocket clip, which is why I assume Metal Complex selected it. But I also suspect he really didn’t give it much of a user acceptance test, as it’s ridiculously difficult to get onto my pocket, and then it’s destructive as all Ache-EEE-Double-Toothpicks on your pocket fabric while attached / removing it. Not good, Dagwood! I decided to order the same alternative 54 mm / 2.126” long, 3D contoured Ti clip that will be selling on the Batch 2 release of the Excalibur to give the knife a fairer shot (and as an appreciation gift to my friend who loaned it to me brand new). I hope it comes in before this post is done. If it does, I will also include information on that clip as well as how it affects the usability of the knife. But right now, the Excalibur is not a carriable knife with that sexy but unusable Timascus pocket clip.

UPDATE: The alternative titanium pocket clip took forever and a day to get here! Let’s add coverage of that after we discuss the original clip immediately below.

But as I am doing a review of the knife as it was loaned to me, I want to cover a bit of the detail on Timascus clip. Per the Reverse Tux Kunwu Crew web page, it’s identified as a 3D TI clip. This likely means that it’s a piece of Timascus material that was created by 3D machining, which I have to assume is a reference to it being contoured milled. It’s a needlessly obtuse way to refer to a contoured pocket clip. Given that, I then have to assume that a 2D clip is just flat, right? I wonder what a 1D clip would be like? Perhaps it would be very straight and incredibly thin. But if they included the amount of time it took to make it, then it would have been 4D!

The Timascus clip provided has a beautiful mix of purples and blue swirls, with a nice addition of golden orange areas to boot! Gorgeous! Even if it is a pocket-shredding monster in disguise.

Timascus is a titanium Damascus alloy of multiple titanium grades, typically a blend of TI-6AI4V Grade 5 and TI-CP (commercially pure) Grade 3. These various grade layers are welded, forged, and machined. The process of grinding results in a lot of chips and other wasted material, sometimes as much as 80% of the starting sample, and that scrap material is not reusable. And you wondered why this stuff is so expensive!

The Timascus clip is 43.65 mm / 1.732″ long, and given the handle length of 121.41 mm / 4.779″, this results in a clip-length-to-handle ratio of 36% — another MC design choice, as he hates when clip-to-handle ratios exceeds 50%.

The Excalibur Timascus pocket clip tip-up only and has a steep ramped toe 3.42 mm / 0.135″ wide, resting just behind the external relief cut, and the under-clip part of the scale has a smooth texture between the toe and the attachment. The handles do not offer ambidextrous clip placements, but have no fear, my Mollydooker friends. MC also sells dedicated left-handed models of the Excalibur, with southpaw clips and Cuddy Wifter frame locks just for you! You’re welcome.

I finally got the new, alternative titanium clip in the mail! This clip is not as fancy-pants as the Timascus clip, but nor is it as pocket-shredding. I think it looks pretty good, in fact, and it’ll add wear time to your favorite denims! Sweet!

This is how the Batch 2 releases of the Kunwu Excalibur will be equipped by default.

This new clip measures 47.30 mm / 1.863” long, which is 3.65 mm / 0.144” longer than the original Timascus clip. This means the new clip increases the Clip-Length-to-Handle % from 36% to 39%. Not enough of a difference to make a difference.

As for the fasteners, there are none visible on the show side, which is super nice. The clip side of the handle only has fasteners within the pivot, the LBS disc, the steel lockbar insert, and the single pocket clip screws, all of which have T8 sockets (even the lock bar insert fastener, but don’t go screwing around with that, OK? Sheesh!). Very nice!

Weight

We have a hefty, weighty issue to consider here. The Excalibur is definitely no ectomorph, no gentlelady’s folder, no skinny Stiletto, no absurdly-light weight, cheap wooden-handled Opinel. Not a chance. The Kunwu Excalibur is definitely a hefty, husky, pudgy little thang with its 3.7” long, .135” thick blade and its 4.75” long, ½“ thick, titanium integral handle, has enough heft for multiple knives. The Excalibur tips the scales at 162.17 g / 5.72 oz. MC himself says that 6 oz. is the limit that he deems as not carriable for a pocketknife. The Excalibur comes surprisingly close to that limit, but it does come just under the bar. It works for him, but the weight of the knife may well be a challenge for others. It’s like a sleek, sophisticated knife but has a really big, bodacious booty (or a bloated beer belly – you pick the gender metaphor appropriate for you), over which the Excalibur is privately rather embarrassed.

Here’s how to find out if this corpulent chubster will work for you. Get a zip-top baggie and put in a roll of pennies and 6 quarters. That’s basically the weight of this ponderous pocketknife. It won’t at first seem that heavy, but put the coin baggie in your pocket and carry it around for a while. Better yet, to ready get the experience, use a spring steel binder clip to attach the baggie onto the edge of your pocket, so you can feel the weight hanging there. If it pulls your pants down, either get yourself a belt that fits or move on from this shattered dream. But if that binder clip baggie works out for you, you’ll already have the first $2.00 in hand to help save up for your own Excalibur!

By the way, the weight-to-blade-length ratio of the knife is an unfortunate 1.72. MC much prefers a 1.00 ratio. But as I once told Mick after meeting him backstage, “You can’t always get what you want.”

Design Considerations

The Excalibur is, in my own design considerations, a very impressive knife. Metal Complex has taken full advantage of his rich and deep experience in handling so many folders in both his knife collecting hobby and online media career. When you see the Excalibur for the first time, you see a beautifully built knife using impressive materials. But when you sit down and really take a look at it, especially in person, you see so many little design-y things that only a true knife enthusiast would understand and appreciate. For example:

Blade

- The blade thumb studs are also used as external opening stops, which fit into correlated cutouts in the handle.

- Employing a longer opening hole with only a moderate perimeter edge chamfer to allow optimum opening access.

- The absolute ease in using that opening hole to reverse flick that heavy blade with a BAM!

- Using Vanax, an excellent blade steel (it’s not MagnaCut, but it’s still pretty good in its own right!).

- Finishing the blade to a very fine grind, top quality satin finish.

- Applying an extremely scratch-resistant DLC coating, that, due to the above blade finish, becomes a gorgeous, near glossy black finish.

- Presenting the blade devoid of any extraneous blade markings, but still adding the blade steel marking in a spot that’s hidden when blade is deployed.

- Adding a visually interesting, kooky groove that turns out to be one of the most interesting fullers available on a production knife.

- The wide finger choil enables the user to choke up for finer, more precision-controlled cuts.

- The same choil is correctly placed relative to the plunge grind line so that the blade can be easily sharpened over the course of years.

- Extending the jimping much further down the spine, through the full length of the opening hole, complements the wide finger choil.

- Adding a smooth, sexy time crowned spine.

- Ensuring the heat treatment of the blade steel optimizes both the toughness and edge retention.

- Specifying a high flat grind makes the non-thin blade as slicey as possible.

Handle

- Providing a full-size Ti-6AI4V handle.

- Make that a full-size integral Ti-6AI4V handle!

- All edges chamfered smooth, ensuring that grasping the handle is impressively comfortable.

- Fully textured, contoured handle body.

- Excellently executed frame lock with stout, steel lockbar insert that attains a structurally strong lock-up.

- Oversized, captive pivot with milled-engraved manufacturer’s logo (keeping the blade free from markings).

- Dual Timascus pivot collars!

- External frame lock relief cut with rounded internal edge corners and an added milled logo of the designer (MC).

- Generous cutouts on either side of the frame lock access.

- Redundant lockbar overtravel stops, including an LBS disc system that prevents lockbar compression into the frame.

- Smooth, crowned integral handle topline.

- No visible fasteners on show side of handle.

- All fasteners on clip side are the same size – T8.

- Options for full left-handed design, including both pocket clip and frame lock.

- Beautiful, short-length, milled Timascus pocket clip (even if that clip didn’t function as desired).

- Space underneath the pocket clip has texturing removed.

- No handle space was wasted or were the aesthetics compromised by putting a lanyard fob mount on this knife!

Overall

- Selecting the respected Kunwu Knives, known for its high-quality manufacturing, fit and finish work, and superlative blade heat treats, to be the OEM

- Keeping the cost of this knife as accessible as possible.

All these individual design decisions (and more) in aggregate create a knife design that will impress and please most knife users.

Original Packaging

I must admit that I don’t have the original packaging. The Excalibur Reverse Tux knife was lent to me by a wonderful friend. However, I did see on one of the many repeated viewings of MC ‘s Excalibur videos when he unboxed the final version of Excalibur was introduced. As a result of that quick moment, I can say this.

The Kunwu Excalibur is enclosed in a pearlescent white, heavy paperboard book style box with a magnetic closure. The lid has a printed gold Kunwu logo. Inside the box is a white knife tray insert, in which the knife is set. I suspect that the knife was enclosed in a satin-looking white bag (which was used on other Kunwu knives). Beyond that, assuming all of that is correct, I have no idea what else would be included. Whatever.

Knife Karen Nitpicks

The Kunwu Excalibur is a great knife. Well, it would be great if a couple of small things were, you know, changed. Hmm. Some of those things do kind of bother me. I have to believe that if those things weren’t fixed, I’d be upset! In fact, these are really important issues to me! Now I’m roiled up! I demand to speak with the manager! Right now!

- The blissfully blue Timascus clip, brazenly bold and breathtakingly beautiful, becomes a belligerent bully—brutally biting, butchering, and battering your baggy, beloved, bell-bottom britches with every bothersome buck (aka the clip is too tight!).

- The thumb studs, tightly tuned and tenaciously tough, transform every attempted thumb-thrust into a taxing, torturous trial, totally turning any task of trouble-free toggling into torment (aka the thumb studs are too hard to use).

- The detent is disastrously dense and decidedly daunting, defiantly denying any deft deployment, demanding determined digits, and delivering only disappointment to daring, dexterous users (aka the detent is really heavy).

- Despite its dazzling design, decadent details, and deluxe price, this distinguished dagger is disappointingly delivered with a dull, dated, dreadfully drab frame lock, depriving devoted devotees of the delight and drama of a dynamic, daring new deployment device (aka frame locks are boring).

- The titanium handle, though vaunted as very valuable, is vexingly vitiated by a vulgar, vehicle-vault-type veneer, the visual vibe yielding a vastly vapid, visibly vanilla, and vehemently verbose variation (aka the texturing looks like pickup truck toolboxes).

- This premium piece parades a prodigiously prolonged blade and a preposterously ponderous, one-piece, integral titanium handle, producing a pocketknife so portly and plodding it practically pulls your pants to the pavement (aka it’s heavy!).

Price

Like all knives, the price of a knife depends upon where you buy it. But in the case of the original batch of the Kunwu Excalibur Reverse Tux knife, you can only buy it from Kunwu, so the MSRP and the Retail price are the same at $429. However, if you go looking for it on the open secondary market, prepare to pay $500+. The good news is that the upcoming Batch 2, which is due to deliver in June, is selling on Kunwucrew.com for $405 (with a strikethrough price of $489, implying that it’s on sale, but they’re only underbidding themselves, so whatever).

Verdict

When I saw the trend emerge of video knife reviewers being asked to design their own pocketknives, I wasn’t sure what to think. After all, these folks are just not trained designers. Then I started watching the reviewers review the knives of their friends. To be honest, there’s simply no possible way that one KnifeToober will diss another KnifeToober’s knife designs, knowing that they will also be soon releasing their own knives. Besides, these folks are also friends in the community. You have TriState_EDC, Advanced Knife Bro, Neeves Knives, and of course, Metal Complex (there are many others as well). You don’t see negative reviews of their own knives between these folks. You do see some honest feedback, but the reviews themselves trend toward positive to very positive.

You might look at this situation and think this is a KnifeToober cabal just propping each other up. But I challenge you to think again. What I have found is that these knife reviewer folks, who look at so many knives from so many manufacturers on a weekly, if not daily, basis, have figured something out. What I see is the recognition of the good, the bad, and the ugly of so many production knives that when they get the chance to design their own, they already know how to identify the right features and all the little details that separate a good knife from a great knife.

I see this work clearly done with the design of the Kunwu Excalibur. You might think, “Hey, how hard is it to put in a drop point blade in a titanium handle? That build is so common these days!” No argument there with that incredibly reductionist viewpoint. But look just a bit closer and the difference between those common, just above the budget knives category, cutters, and you’ll see for yourself. Sure, you can pick up a CJRB Large Pyrite Drop Point Button Lock Knife Titanium handle knife at BladeHQ right now for $80. There’s nothing wrong with a CJRB Pyrite. The Kunwu Excalibur costs 5+ times that much. But these simply aren’t the same knives. The CJRB comes equipped with a thin (0.110” per BladeHQ), Spray-Form AR-RPM9 steel blade (likely hardened to ~58-59 HRc), a pair of smooth titanium scales, a very plain, non-captive pivot, a run-of-the-mill push button plunge lock, and a stamped steel pocket clip. And to make the kids happy, it even comes with a lanyard hole! Sigh. It’s blander than a boiled potato in a snowstorm. And that will do if that’s all you want.

The Excalibur hosts a highly polished, particle-metallurgy Super-steel, Uddeholm Vanax SuperClean, donning a thin coat of mid-glossy DLC. The handle is a titanium integral, a setup that is much harder to manufacture as it’s milled from a solid block of Ti. That integral handle is both contoured (even more difficult to mill) and has a fine, textured surface (yeah, it’s akin to mini diamond plate, pickup truck toolboxes, but it’s still got grip). The action is based on a pair of milled, engraved, and DLC-coated, captive pivots, surrounded by a pair of elegant Timascus pivot collars. The contoured pocket clip is also milled Timascus. But wait, there’s more! A lot more.

Kunwu is known for its meticulous standard with their steel heat treats, and the Excalibur is hardened to between 60-61 HRc, exactly where Vanax is meant to be. MC added what I called a kooky groove that follows the line of the stadium-style oval opening hole along the top of the blade. MC says this is a fuller, so I will stop calling it a kooky groove now (maybe). The thumb studs are nicely shaped, avoiding those upside-down ice cream cone shaped studs that painfully dig into your thumb like a slightly dulled ice pick. The spine is beautifully crowned for both comfort and a touch of Italian knifemaking class.

The pair of DLC-coated thumb studs serve double-duty as the external stop pins, which nestle into a small, shouldered spot at the front top of the Ti handle. The Excalibur uses a frame lock — yeah, frame locks are old and boring in general, but when they are well-designed and well-executed, they can still go a long way in properly supporting a good blade. In this case here, Kunwu does very fine work by getting the steel lockbar insert lock-up to be in the 40% range without any lock stick or blade play. But the design by MC ensured that the lockbar used an external relief cut (better for lock strength and durability), whose inside corner edges were round milled, not done in 90° cuts that significantly weaken the lockbar’s durability. And the cherry on top here is the milled (not laser etched) image of the Metal Complex Knight’s Helmet logo placed within the relief cut field. The lockbar also hosts redundant overtravel stops, including the Hinderer-style LBS (lockbar stabilizer) disc, which not only serves as an overtravel stop, but also serves to prevent the lockbar from being compressed downward into the side of the titanium handle.

The show side handle has no visible fasteners, due to the fact, of course, that it’s an integral handle with a captive pivot. The top (spine side) of the handle is softly crowned along its full length, and all edges are chamfered for comfort. The design of the blade action makes opening it so enjoyable with an easy reverse flick, despite the relatively heavy detent.

So is the knife perfect? Naw. I haven’t found a perfect knife yet (although I’m still waiting for Herman Knives to get back to me!). The Excalibur is a chonky critter, weighing just shy of 6 oz., a weight MC himself says is the limit for a knife he’ll carry (good thing that pocket clip isn’t any heavier!). And speaking of that Timascus pocket clip, this is the most controversial element of the knife. For many people, this viciously tight clip, with its very pointy, V-shaped ramp toe, is a pocket fabric shredder. Luckily, Kunwu is offering replacement, non-Timascus, milled Ti pocket clips that are much less clothing shredders (this alternative clip is the default offering with the Batch 2 release of the Excalibur coming in the next couple of months).

Opening the Excalibur with the thumb studs is much more difficult than I expected. My old, Knife Karen hands really struggled with this. I suspect that the combination of the large detent ball, the wide angle (46°!) from the pivot between the thumb stud placement on the blade and the handle’s center line, as well as the tiny gap between the studs and the knife body cutouts, all contribute to a needlessly difficult knife to open. Of course, with only a sample of 1, I can’t say with certainty if this is a ubiquitous problem or just with the (borrowed) knife I reviewed. (Pro Tip: Hold the handle as low as you can; the thumb stud action works well from here.)

But in truth, the Excalibur is exactly what MC wanted for himself, and Kunwu was an excellent OEM choice for bring his dream into reality. He loves it, the knife sells out, so other people love it, too. I clearly see so many of the little design upgrade details MC put into this knife that I am smitten with it, too, despite my niggling complaints. Overall, it’s all the little, magical details in the wizardry of MC’s design that separates the Excalibur from so many other knives in its class, making it more than worthy of pulling it out the stone – and putting it in your pocket. It’s a great knife. Go get one (while you can). Enjoy! ![]()