Early last year (2023), after reading so many posts on Larrin Thomas’ KnifeSteelNerds.com blog, I decided I wanted to see for myself what all the hype was about with MagnaCut steel. When I began looking, everyone’s favorite super steel wasn’t nearly as available as it is this year. Only a few brands had knives with MagnaCut blades, and most of them were oddly yet seemingly proud to sell theirs with an HRc rating of 60-61. Given MagnaCut’s hardness potential of up to 65, this wasn’t what I was looking for.

It’s almost as if these knifemakers were either not trying or didn’t know how to work with it. I’m guessing it was more the latter, but given the additional processing costs associated with proper steel heat treatments to create hard Martensite and then properly quenching the blade to keep that hardness, then do a cryogenic treatment to harden the steel even more, only to release a bit of the tension in the steel matrix with a proper tempering to improve toughness, well, that time is money, and those tasks are rather time-consuming (as they are for proper heat treat of any steel). Many companies either didn’t know how to do the heat treat right with this new steel (just as many still don’t know how to properly heat treat the much older M390!), or didn’t have the in-house resources to do it right (be it metallurgically-trained bladesmiths, proper heat treat controlled furnaces, cryo treat equipment and expertise, or simply the time to do it in the voluminous scale for the sales they hope to make).

I am a finicky knife purchaser. I have a preference for some design styles, some blade shapes, some knife materials, and I’m not unspeakably rich where I could buy whatever knife I wanted (dammit! I still want a Herman knife!). But it’s not always clear what I think I want. So, when I was shopping for my first Magnacut knife, deciding what was interesting versus not wasn’t easy. The intangible element to an appealing design and style can be hard to suss out in feelings, much less into words. But you know what you like when you see it, right?

I searched for a long time for that ethereal blade that would make my heart flutter. During my online search, I initially discovered the gorgeous Viper Moon, a sexy Italian Fabio of a folding knife, but for the longest time, it was nothing more than a wink and a nod, blade vaporware, an unfulfilled promise made in a 2023 Blade Show video. My curiosity (desire? lust?) for a MagnaCut folder made me impatient, though, so I kept looking for that fulfillment, for “the one”.

It was in late September, 2023, when I heard news of the release of the Benchmade Mini Adamas, model 273-03, featuring a stout MagnaCut blade (the first in the Adamas line with a blade not covered in Cerakote, and I do prefer the look of fine-finished steel rather than a matte coating color that will begin to wear off – and look like crap – in short order!). The 273-03 also featured a beautiful set of carbon fiber scales and, of course, the famous Benchmade AXIS Lock. As a holiday gift to myself (thank you, me! It’s just what I wanted! How did you know?), I found a few discounts I could stack together (gotta love holiday sales), and I finally got my first hunk of MagnaCut goodness.

Let’s go over the details and my impressions of this muscular chunk of MagnaCut.

TL;DR

The Benchmade Mini Adamas 273-03, was a solid upgrade to the Adamas line of knives. It features a non-Cerakote Magnacut blade, contoured marbled carbon fiber scales, and attractive golden bronze accents on the full-length, stacked steel liners, the smooth, conical, dual thumb studs, the pivot collars, and the stamped steel pocket clip. It employs phosphor bronze washers in the pivot and the famous Benchmade AXIS Lock. The knife’s appearance is another clear example of the style of knife designer, Shane Sibert. It’s beefy and robust, feels good in the hand, and equally important, unless you get yourself a nice discount from a retailer selling it, its MSRP of $375 means the butterfly tax is heavy on this knife. Given I got the Italian beauty, my Viper Moon folder, which is an ever-so-slightly larger knife, has a beautifully shaped, crowned & usefully jimped modified sheepsfoot MagnaCut blade (offering both thumb studs and an excellent flipper tab), textured and chamfered Fatcarbon scales and several titanium accents (including a half-handle length, crowned Ti backspacer) for less than half the price of the Benchmade, the cost-to-value ratio of the Mini Adamas 273-03 is not so great, in my humble-not-so-humble opinion.

Pros

- Uncoated, drop point MagnaCut blade

- Beefy design

- Contoured, chamfered marbled carbon fiber scales

- Beautiful looks with bronze accents on thumb studs, pivot collar, liners & pocket clip

- Accessible thumb studs

- Milled steel liners to reduce weight

- Open handle design made for easy cleaning

- Robust and comfortable hand feel

- Classic Shane Sibert knife design

Cons

- Blade bounce when closing this knife is like a steel Wham-O Superball!

- Butterfly tax is too damn high!!

- Smooth surface thumb studs make reverse flick difficult

- Tested blade hardness was disappointingly low

- Blade fuller inaccessible for reverse flick

- Numerous imperfections in the carbon fiber surface finish

- Blade spine edges are not chamfered enough

- Pocket clip is too long

- Unsightly polished, uncoated scale fasteners in dark CF scales in stinkin’ T6!

- 3 Sibert holes in scales

- Pivot is so plain that even the rain in Spain mainly falls on it

Tech Specs

Brand | Benchmade |

Website | |

Manufacturer | Benchmade |

Origin | Oregon City, OR, USA |

Model Reviewed | Black Series Mini Adamas 273-03 |

Designer/Design | Shane Sibert |

Model Launch Year | 2023 |

Style | Folding Knife |

Lock Type | AXIS Lock |

Opening Type | Manual |

Opening Mechanism(s) | 1. Dual, smooth, clipped conical, bronze-colored steel thumb studs |

Pivot Type | Captive, uncoated steel pivot using shallow, conical shape with rounded peak and a T10 fastener, encircled with a golden bronze pivot collar |

Pivot Mechanism | Phosphor bronze washers |

Length Closed | 113.80 mm (4.48″) |

Length Opened | 193.33 mm (7.61″) |

Weight | 123.00 g (4.34 oz.) |

Original Packaging | Heavy, rigid, Black Class paperboard, full telescope box and a dense, large-cell foam lining glued to the lower. Knife is enclosed in a black, satin, drawstring bag & box includes marketing materials. |

Edge | Plain |

Shape | Drop Point |

Material | CPM Magnacut |

Claimed Hardness HRc | 60-62 |

Tested Hardness HRc | 59.28 |

Blade Length | 85.70 mm (3.37″) |

Cutting Edge Length | 81.10 mm (3.19″) |

Primary Bevel Angle | 9° |

Height | 25.24 mm (0.99″) |

Thickness | 3.54 mm (0.139″) |

Main Bevel Edge Thickness | 0.84 mm (0.033″) |

Thumb Studs Span | 13.64 mm (0.54″) |

Finish | Stonewash with very finely milled vertical lines |

Features | 46.48 mm (1.83″) fuller in flat |

Grind | Sabre grind |

Swedge | 54.26 mm (2.14″) swedge |

Fuller | Yes |

Jimping | Coarse, 3-cut jimping on the blade thumb ramp before the studs. The handle is littered with the same, coarse jimping, with 7-cut jimping on the handle front, both above and below the pivot, 7-cut jimping at the bottom rear, as well as 5-cut jimping on top rear and the butt end of the handle. |

Blade Markings | Show side: Company logo at top of bevel |

Sharpening Choil | Yes |

On-Blade Opening Assists | Thumb studs |

Materials | Marbled carbon fiber |

Color | black |

Scale Thickness (includes liner) | 4.90 mm (0.19″) |

Scale Texture | Ultra-fine texture. Just below smooth |

Handle/Scale Features | Contoured, chamfered, 3 drilled out holes in typical Shane Sibert style, with a rise in the finger grip at the center and fingerguards at both ends. |

Liners | Dual, full-length steel liners, milled for weight reduction |

Opening Stop Pin Type | Stop pin mounted through handle |

Closing Stop Pin Hits Sharpening Choil | No |

Handle Length | 113.80 mm (4.48″) |

Closed Handle Height | 31.94 mm (1.26″) |

Handle Thickness | 16.07 mm (0.63″) |

Pivot Center-to-Thumb Stud | 22.74 mm (0.90″) |

Thumb Stud-Angle-from-Vertical Center | 35° |

Thumb Stud Tip-to-Scale-Edge Clearance: Show Side / Clip Side | 6.00 mm (0.24″) / 6.00 mm (0.24″) |

Pivot Center-to-Open-Knife Fulcrum | 13.00 mm (0.51″) |

Integral Handle | No |

Backspacing Type | Standoffs |

Backspacing Material | Steel |

Backspacing Color | Golden bronze |

Backspacer Features | Shouldered and colored to match the liners, pocket clip and pivot collar |

Lanyard Mount | Lanyard hole |

Pocket Clip | Stamped, deep-carry style |

Clip Material | Steel |

Clip Color & Finish | Golden bronze PVD |

Clip Placement | Right-handed only, Tip-Up |

Clip Length | 58.08 mm (2.29″) |

Clip Length-to-Handle % | 51.03% |

Clip Features | Coated, surface-mounted with spoon bill and butterfly logo stamp |

Fasteners | T6 button-top steel body screws, 3 per side, and 2 additional button-top screws on clip side to secure the clip |

Who is Benchmade?

Benchmade is a privately-owned, knife-making company that was founded in 1979 in California by Les deAsis. They began their cutlery mission as a maker of Bali song (aka fan or butterfly-style) folding flipper pocketknives, a knife design that originated in the Philippines a long time ago (now you know why the company logo is a butterfly!). The company was originally named Bali-Song, and in the early 1980s, it was renamed Pacific Cutlery Corp, only to be renamed again in 1988 to the current name, Benchmade. The company relocated to Clackamas, OR in 1990, and then relocated again in 1996, just a few miles down the road, to Oregon City, both cities being suburbs of Portland, OR.

Over the years, Benchmade expanded their product lines to include a wide variety of knife types, which they categorized into 3 classes, such as Recreational (known as Blue Class), which include both working, outdoor sporting, hunting, and fishing knives; Tactical (known as Black or Professional Class), designed for folks in the military, law enforcement, public safety, and, of course, LARPers; and Collector (known as Gold Class), which include high-end, limited edition models as well as true custom models. They also have a full line of culinary knives. All their knives are manufactured in their Oregon City factory.

Benchmade produces knives that use a variety of opening mechanisms, including manual folders, spring-assisted opening knives, automatic side openers (switchblades) and OTFs (out-the-front) knives, gravity knives, fixed blades, and, of course, butterfly knives. The company is noted for using a wide variety of blade steels and handle/scale materials in their designs. Many of their knife design models have become iconic in the pocketknife community, such as the Osborne 940 & 945, Bugout 533 & 535, Griptilian 551 & 556, Freek 560 & 565, Anthem 781, Shootout 5370, Claymore 9070 & 9570, and most certainly, the Adamas 273 & 275 (as well as many more).

Today, Benchmade holds tight to their 100% USA-made ethic, and they are popularly known for making high quality knives at, well, some would say, excessively high prices. No one denies that Benchmade knives are excellent knives using (mostly) excellent materials (their plasticky, Grivory handle material feels rather cheap and is rarely anyone’s favorite), but their knives are well-known and often criticized for their “butterfly tax”, a perceived, high-price markup based more on the brand name’s implied value rather than their knives’ actual materials, design & craftsmanship value. While there will always be fanboys of Benchmade (as there are for every major knifemaker) who don’t care about the costs, a number of people in online communities actively complain that the large degree to which Benchmade marks up their prices negatively affects the overall value proposition of their knives.

Introducing the Benchmade Mini Adamas 273-03

Before the Mini Adamas 273-03 came out in 2023, there was the original Adamas 275, which was first released way back in 2011. It was a big, manual folding knife that measured 8.7” open and 4.88” closed. It featured a 3.78” Cerakote-colored drop point blade made of D2 tool steel sporting G10 scales. It was a hog of a knife, weighing in at a massive 7.7 oz.! Back in the day, D2 was a highly lauded blade steel. But over time, as newer and better blade steels came onto the market, D2, which was invented way, way back in 1918, lost its luster. Benchmade responded to this in 2021 by releasing a new Adamas in the much more robust blade steel, CPM CRU-WEAR with the familiar Cerakote finish.

Top: Benchmade Mini Adamas 273FE-2 in Cerakote CPM CRU-WEAR & OD Green G10; Bottom: Benchmade Adamas 275FE-2 in Cerakote CPM CRU-WEAR & OD Green G10

In the same year, they also released the Mini Adamas 273, a smaller version of the Adamas line, also in CPM CRU-WEAR with a Cerakote finish and G10 handle scales, but it was hardly a “mini” knife in any way but in name. Compared to its big sister, it was a bit lighter and a bit smaller, but the Mini Adamas was not small. More importantly, it was every bit as tough and rugged as the original. And then in 2023, Benchmade released the Mini Adamas 273-03, a new, higher-end model boasting a stonewashed MagnaCut blade and beautiful marbled carbon fiber scales. This is the model that won me over. Let’s talk about the Benchmade Mini Adamas 273-03 and see what it has to offer.

Details and Specs

I do like the look of the Sibert-styled Mini Adamas 273-03. It’s definitely not as big as the original Adamas, but make no mistake – this is no mini knife! One of the Mini’s best features is the full hand feel. Its stout, beefy handle with its contoured scales very comfortably fills out your hand for a very secure grip.

Let’s cut the crap and dig into more details!

Blade

The MagnaCut blade of the Mini Adamas comes in a sabre-ground, classic drop point style with what Benchmade calls a stonewash finish.

Interestingly, if you look at the blade under a microscope, or even in just a bright light source, the blade has vertical, micro-milling lines down the width of the entire blade. They’re a little hard to see, but you can feel them by scraping a fingernail along the face over the length of the blade. While I have not seen every knife blade in existence, it seems to me that this is not a common type of blade finish. It’s not simply vertical scratch lines from a belt satin finish; these lines are so regular that it looks to be precision machining from CNC milling. Now I did notice those micro-milling lines are very prominent on the tip end and all but fade out into surface smoothness near the ricasso at the back. From this sample of 1, I feel free to speculate that this presumptive CNC milling work must be the way Benchmade initially grinds their steel blanks into knife blades. It must be true, because I said it! 🤪

The blade features coarse jimping – 1/8” (3.18 mm | 0.125”) from ridge to ridge – which is not really very effective for helping establish a secure grip against the skin of your thumb. There is absolutely no spine crowning, although, while it won’t significantly abrade your skin when scraped along the edge, it’s still needlessly squared. (Quiz: Do you know what the opposite of smooth, chamfered blade spine crowning is called? Spyderco!). Benchmade should have knocked down the 273-03’s spine edges a bit more for sure. It’s uncomfortable when scraped against my delicate Knife Karen skin!

The blade also presents a swedge and a flat with a narrow fuller that runs up from the rear to just under 60% of the way toward the tip, as well as a good sharpening choil.

The blade markings are typical Benchmade. The blade’s show side has, in a very light gray engraving at the top of the saber grind’s primary bevel, next to the ricasso, the rather large, antenna-less, Benchmade butterfly logo atop of, in stacked micro-text, “U.S.A.”, then “273” below that.

On the clip side, in front of the thumb stud on the flat, is engraved “CPM MAGNACUT” in the same very light gray text. In the same-colored engraving, at the top of the primary bevel next to the ricasso, is the designer’s logo that reads (in stacked text), “SIBERT” in bolded text above the word “DESIGN” in fine text, all enclosed in 3 concentric oval lines, presented as thin, thick, and then a thin line again.

Out of the box, to be perfectly honest, the blade was not very sharp. Above the blade edge, the primary bevel is rather thick at 0.84 mm (0.033″), so you can’t really expect it to be slicey-dicey, but it wasn’t just that. It just wasn’t very sharp! I ended up resharpening it myself to 17° using several, progressively finer grit diamond stones and finished it with a couple dozen strokes on my homemade leather strops coated with successively finer diamond pastes, which helped a fair bit. On the positive side, the blade features were perfectly even and symmetrical on both sides.

Blade Dimensions

The sturdy MagnaCut blade measures at 3 3/8” (85.70 mm | 3.37″) in length with a 3 3/16” (81.10 mm | 3.19″) cutting edge. The blade height is 127/128” (25.24 mm | 0.99″), has a spine thickness of 9/64” (3.54 mm | 0.139″) and has a chonky primary bevel (just before the secondary bevel edge) thickness of 1/32” (0.84 mm | 0.033″). Benchmade cut the primary bevel to be 9° (I can’t report on the factory edge angle as I sharpened it before I got my laser goniometer). The blade features a 1 53/64” (46.48 mm | 1.83″) fuller in the flat that starts just underneath the open blade handle and a swedge of 2 1/8” (54.26 mm | 2.14″) that runs from the middle of the blade down to the tip. And if you care, the thumb stud span across those tall, smooth cones came in at 17/32” (13.64 mm | 0.54″) wide, which is plenty of access to easily open the blade without sticking out past the handle body.

HRc Rating

Benchmade reports that they heat treated their MagnaCut steel to a hardness of 60-62 HRc. Using my portable Leeb Rebound Hardness Tester, I ran 2 sets of calibration tests on my new NIST-certified Rockwell Hardness Steel Test block, which is certified to be 61.22 HRc with a variance of +/- 0.5. Those sets of calibration tests, done twice, returned in Leeb HLD scores, came out as 823 and 829. The average of which, 826 HLD, per my scientific mathematical calculation table mentioned in a previous post in the link above, converts the hardness of that test block to be 61.79 HRc. That’s within */- 0.5 points of the block’s rated HRc, so my Leeb Rebound Tester was ready to test the Benchmade blade.

I then carefully conducted 2 sets of 5-rebound tests, one on each side of the Mini Adamas’ blade tang, the average of the 5 tests each set came back as 796 and 809 HLD (I actually took many more tests than 2, but if the rebound tester shifted, was not perfectly flat and perpendicular to the blade, or I got an unexpectedly low reading within the 5-test set, I started over). I then averaged the 2 results of each set’s averages, which came to 802.5 HLD, and then I converted the HLD results into HRc. The Benchmade MagnaCut blade stock on my Mini Adamas knife came back to actually be 59.28 HRc, just a tad below the low end of Benchmade’s claimed blade steel hardness rating. I’ve definitely seen worse differences between claimed hardness and tested hardness in other knives, but this score is still disappointingly low for MagnaCut. Hey Benchmade, you need to have a consult with Dr. Larrin Thomas on how to properly harden his steel!

Opening Mechanisms

The Mini Adamas blade can be opened via the easily accessible thumb studs, which is great. The studs are not pointy sharp like on my beloved Viper Moon, and the span across both sides of the blade are nearly 1.5mm wider than the Moon, and a solid 1.6mm wider than the excellent Civivi Vision FG.

However, unlike the Viper Moon, which has a fantastic, jimped, and small but perfectly placed flipper tab, the Benchmade Mini Adamas only offers thumb studs. Yeah, it has an AXIS Lock rather than the button plunge lock of the Moon (a typical omission on crossbar-style lock knives due to the lack of a detent ball and the expected level of detent tension). Of course, you can always use that AXIS Lock to unlock and flip open the knife.

Unfortunately, the blade’s fuller is not functional as a reverse flick mechanism. Benchmade chose to completely bury the blade fuller into the handle. This means the best reason to have a fuller on a folding knife blade has been negated. Now all the fuller accomplishes is to reduce the overall weight (okay, that works), improve blade aesthetics (that also works) and serve as a LARPer’s erotic dream, having a “blood groove” in their tactical knife (riiiiiight).

What is the AXIS Lock?

Of course, Benchmade is very well-known for the famous AXIS Lock, a blade lock technology originally invented and patented in 1988 by independent knife designers Jason Williams and Bill McHenry.

As the origin story goes for Benchmade, in 1997, both McHenry and Williams lived in Charlestown, RI and were regular visitors to the town’s local knife shop, Cove Cutlery. The owner of that shop told them that Benchmade founder Les deAsis was also a regular visitor to the shop, so McHenry asked for a quick call the next time deAsis came in. Well, that day came in November 1997, and wouldn’t you know it, McHenry suddenly appeared when deAsis was still visiting. McHenry took the opportunity to show deAsis the innovative lock design he and Williams had invented. Naturally, deAsis was keenly interested, so he flew both Williams & McHenry out to the Benchmade Oregon City HQ a month later to demo their lock design to the Benchmade engineers. They were suitably impressed, so a business deal was struck. Benchmade purchased the unnamed lock design and its patent (US Patent Number 5737841) and officially dubbed it the AXIS Lock. Just a little over a year later, in 1999, Benchmade released their model 710, their first knife using the AXIS Lock.

Well, all good things must come to an end, including patent legal protections, and on July 12, 2016, Benchmade’s patent on the AXIS Lock expired. Today, any knifemaker can use the dual omega spring and lock-pin-against-blade-tang-notches lock design on a new pocketknife, which is now commonly referred to as a crossbar lock. The one caveat is that Benchmade’s trademark for the term “AXIS Lock” is still in effect, so no one else can use that name in their lock’s product marketing.

How the AXIS Lock Works

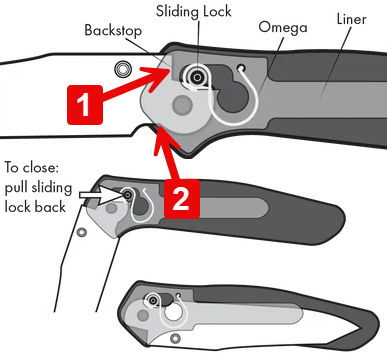

Fundamentally the AXIS Lock is a spring-tensioned, cylindrical steel lock pin, set within a slot in the liners & scales, that lies perpendicular to the blade tang. It slips into one of a pair of notches along opposite sides of the tang to either securely lock the blade open or hold the blade closed. The lock is released by pulling back on the lock pin’s end studs against the spring tension to extract the lock pin from either the open or closed notch. The springs employed here are a pair of curled wires (one each on the external side of the steel liner cartridge) that are shaped much like a fishhook (or as some describe, like an upside-down version of the last letter in the Greek alphabet, omega – Ω). One end of the omega spring wraps around the lock pin, then the spring wire descends down into a ¾ loop, where a bend in the other end fits into a small hole in the steel liner. Let’s look at a diagram to see how this works.

When the blade is opened, such as with the Mini Adamas, the opening push pressure on a thumb stud overcomes the moderate dual-omega spring retention pressure detent of the blade tang’s smaller, closed notch, causing the lock pin to momentarily move back and compress the springs. Then the pin rides along the smoothly rounded blade tang until the blade spine is parallel with the back of the knife handle, where the other, deeper L-shaped open notch in the blade tang allows the lock pin to spring forward into the horizontal edge (No. 1 shown above) and set deeply into that notch. When the open notch in the tang becomes accessible to the lock pin, a separate, externally mounted stop pin simultaneously contacts the vertical backstop edge of the L-shaped open notch in the tang, preventing blade over-travel. At this point, the blade is fully opened and is securely locked in place of the open notch by both the stop pin and the steel lock pin, pushed forward into place by the tension of the pair of omega springs, into both edges, blocking any movement of the blade.

To close the knife, the user pulls back on one or more of the lock pin studs (hey, you have options!) against the dual-spring pressure to extract the lock pin from the open notch’s horizontal edge in the blade tang. At this point, the blade is free to fall closed. And when the lock pin encounters the rotating tang’s closed notch (a very small notch just behind the sharpening choil – No. 2 shown above), the omega springs once again push the lock pin forward into that notch, giving the pin enough pressure to securely hold the blade closed. When closed, the lock pin also serves as the closing stop pin, pressing against the back of the sharpening choil, preventing over-travel on this end of the blade movement.

Some of the key advantages to the AXIS/crossbar lock include:

- It’s ambidextrous in function, giving southpaws an equal experience in operating their pocketknives

- It’s conveniently placed on the knife for easy, one-handed operation, unlike back locks (looking at you, Buck, Spyderco & Cold Steel)

- The users’ fingers are never placed in the path of the blade when closing the knife

- It strongly and securely holds the blade open

- The lock mechanism is smooth and allows the blade to swing freely

Disadvantages of AXIS/crossbar locks:

- The long-term durability of round wire omega springs is uncertain, as many users have reported the springs breaking (Benchmade has recently changed their AXIS Lock to use more durable, flat wire omega springs)

- Some companies (ahem, Benchmade!) don’t include any of the inexpensive, replacement omega springs with their knives (for the record, Benchmade’s lifetime warranty covers repairing your knife’s broken springs for free, but your knife is out-of-pocket for a couple of weeks while you wait for the fix and return shipment. Do note that this warranty only applies to the original buyer, not for buyers of used Benchmade knives)

- The complexity of the lock, compared to more simple locks, adds to the cost of a new knife

- When new springs are stiff, it can be quite difficult to pull back the lock pin without using both your finger & thumb

I like the AXIS Lock on the Mini Adamas. When I first got it, the springs were really tight, and it required me to use 2 digits to release it. However, I worked the knife to break it in, which includes the lock’s springs, and now I can release it easily with just my thumb. Was it just me getting used to the lock or was it the springs breaking in? It’s probably a bit of both, but I really like it now (like DCA, I am a big fan of blade locks that don’t require exposing your digits to the falling blade!).

Knife Body & Scales

The handle is definitely one of the best features of the Benchmade Mini Adamas 273-03. It starts with the beautifully contoured, marbled carbon fiber scales. Benchmade identifies the scale color as black, but to me, it looks like a dark charcoal at most, and due to the marbled “crystallization” look that reflects patches of light in different ways, it can look even lighter than that. The scales are nicely contoured, the edges are nicely chamfered, the thumb stud area is scalloped to add to the accessibility of the studs (oddly, there are similar such scallops at the rear of the handle, which serve no useful purpose, and due to the dark color, don’t offer any aesthetic benefits, either). Along the underside edge of the handle, there are 2 sets of large, finger grip contours at the front and the back, separated by a rising peak in the center, and enclosed by a pair of finger guards. I really like how the scales contribute to the great look and hand feel of the knife.

The pair of raised finger guards at the ends of the handle can be problematic for some people, as this design may make some people feel that their hands are locked into one position, and if that space in handle is too small, it can make gripping the knife very uncomfortable. Luckily, the handle size in the Mini Adamas is plenty large enough for an easy, 4-finger grip with my Knife Karen hands. Now I admit, if you are a member of the Jeff Dabe League of Monstrous Mitts, you might feel a bit cramped, but for the rest of us mere mortals, the handle is very comfortable.

The scales are marred a bit by a few issues, though. For starters, the scales are very smooth! While that sounds nice to the touch (and it is!), it’s not so hot for grip retention. It is a bit slippery, at least to me. Secondly, if you look at those beautiful scales in a good light, you will see (at least I did) small patches on the carbon fiber where the surface finish was not completely done. You see small areas where the surface was not completely finished (aka you see small sections where the CF is not been smoothed). While it’s not at the level of criminal negligence, for the price of a Benchmade knife, it’s close, as the quality of the finish should be better than this. Lastly, of course, there are the controversial, triple Sibert holes. This set of triple handle holes are a common feature in Shane Sibert knife designs. Many people hate the look, while others either really like it, or are ambivalent about it. Count me in the last camp there. I certainly don’t hate them, and I do acknowledge that the holes, which also go through the liners, reduce the overall weight of the knife, which is good for an already stout knife.

So why does Sibert put these holes in his knives? I heard one person claim that Sibert adds them as a survivalist feature, in which you could use the knife’s handle holes to lash it onto a long stick using woven crabgrass fibers to create a makeshift, blade-tipped spear. This idea seems as obvious as seeing a 6-fingered lumberjack walking down the street. Creating a MagnaCut spear is actually really important, assuming you’re expecting to encounter a woolly mammoth during your survivalist adventure. I could not find any evidence that this is why Sibert adds this feature (nor any evidence of woolly mammoths still lumbering around in the local, neighborhood tundra, either). However, I did find an interview where Sibert said he uses the handle holes to help his thumb index by feel where his hand is on the handle. OK, that’s cool, but I’m not sure you need three of them for that, but there it is.

Underneath the lovely, contoured, and somewhat unfinished, marbled scales are full-length steel liners. The liners are coated in the same golden bronze accent color as the thumb studs and pocket clip. The scales are stacked atop the liners, which gives the handle a thicker feel in the hand, which I appreciate.

The handle has an opening stop pin that is secured with visible, externally mounted screws. The lock pin, which also serves as the closing stop pin, does rest against the sharpening choil, but luckily it’s at the tang end rather than at the edge end (that’ll make Jared Neeves happy).

The Mini Adamas employs a D-shaped, captive steel pivot, which is great, although the pivot face, which is an extremely basic, shallow, rounded cone, isn’t exciting at all. In fact, it’s duller than a bowling ball butter knife! At least there is a pivot collar to prevent a severe case of somnambulism.

Luckily, the pivot has decently tight tolerances, so there’s no pivot lash. The blade rides on phosphor bronze washers (no bearings here), but there are (supposedly) good reasons to use washers over bearings. I heard some people say that washers keep sawdust out of your knife action. Whew! Thank goodness for that, given the immense volumes of sawdust that fill the air inside my house. Luckily, phosphor bronze washers do break in quite nicely, and with a little bit of quality lube and a good pivot adjustment, the free blade swing feels buttery smooth rather than like skating on ice. I am totally good with the bronze washers here.

The Mini Adamas does not include a proper backspacer, but instead employs a pair of golden bronze-colored steel standoffs. Now despite the sizable blade, the handle is deep enough to ensure you will not slice your digits when you touch the gap along the handle back of the closed knife.

Lastly, Benchmade made sure to make the last 3 remaining lanyard users in the world, Jordan, Kent, and Owen, very happy by including a pair of lanyard/fob holes at the top rear of the handle. Oh, goodie.

Handle Dimensions

Let’s get down to the brass tacks of handle measurements. The handle length measures 4 31/64” (113.80 mm | 4.48″) and the closed height comes in at 1 ¼” (31.94 mm | 1.26″), which, unless you are Jeff Dabe (see above), will be a comfortable knife to hold. The scale/liner combo thickness is a fairly stout 3/16” (4.90 mm | 0.19″) – on both sides, which contributes to the overall beefy handle thickness of 5/8” (16.07 mm | 0.63″).

I also collect unusual measurements, just in case you’re as big of a specifications nerd as I am. In my experience, there are several factors that can make opening a knife with thumb studs easy or challenging. These factors include the following:

- The pivot-center-to-thumb-stud distance on the Mini Adamas is 57/64” (22.74 mm | 0.90″). This is important because a higher number can mean less leverage for an easy, fast blade opening.

- The angle measurement between the thumb stud and the vertical knife handle through the pivot center is 35°.

- The amount of access clearance between the thumb stud tips and the edges of the scales on either side was measured for Show Side: 15/64” (6.00 mm | 0.24″) and Clip Side: 15/64” (6.00 mm | 0.24″).

The Mini Adamas provides easy access to the thumb studs and their position on the knife make it easy to open. Nice work, Benchmade!

Another measurement that I find important is the balance point of the open knife. Is it blade-heavy, handle-heavy, or evenly balanced? I measure the distance between the center of the pivot and the fulcrum point of the open knife. This Benchmade comes in at ½” (13.00 mm | 0.51″), which makes it ever-so-slightly handle-heavy. If the measurement was 0, the fulcrum point would be in the center of the pivot, and the front-to-back balance would be perfectly even. Assuming you want that.

Hardware

The factory pocket clip for the Mini Adamas 273-03 is one of those golden bronze-colored PVD hardware accents. It’s a stamped steel, deep-carry clip that looks nice at first glance, but I quickly realized that it was too long for me at 2 19/64” (58.24 mm | 2.29”). This factory clip spanned 51.17% of the length of the handle, and I’m one of those who don’t like clips that go more than 50% down. I also didn’t like that the golden bronze clip stood out like a mini light saber when clipped onto the outside of my pocket. I wanted a shorter and stealthier clip. I ended up going for a much shorter, black powder-coated custom titanium clip from a seller on Etsy.

I really like the quality of the guy’s work, and the new clip measures at 1 15/32” (37.24 mm | 1.47”), which comes in at just 32.72% of the handle length, which to me is excellent. However, he specifically left out one important fact when he was selling me on it. He didn’t reveal until I had already paid up that it would take him 3+ months to make and deliver the new clip to me. It was a bit of a killjoy to wait that long for a pocket clip, but now that I finally have it, at least it works better than the factory clip for me.

The handles of the Mini Adamas offer pocket clip mounting holes at the rear on either side of the scales, which is appropriate for a knife using the ambi-friendly AXIS Lock. The scales technically don’t have flat spots underneath the clip contact point, but as the finish of the carbon fiber scales is so smooth, it’s a moot point.

The fasteners used are, unfortunately, a trio of shiny, button-top, steel screws with a T6 socket. This sucks. First of all, T6? Benchmade, are you mad? I bought some crappy, cheap Torx bits earlier this year from AliExpress that claimed to be made of tool steel (I should have known better). However, when disassembling the Mini Adamas so I could measure the blade hardness, one of the fasteners actually ruined a bit (thank goodness it wasn’t the other way around, where a screw socket got stripped). I then borrowed a friend’s iFixit set of Torx bits and it did the job.

But holy crap, I HATE T6 Torx screws! Benchmade, T6 is so last century! Today it’s T8 or higher! Get with the times, people! And of course, those silvery, shiny button-top screws really stand out visually, in a terribly ugly way, against the beautiful, dark marbled carbon fiber scales. I will eventually replace these crappy, cheap factory fasteners with black-coated, flat-top T8 screws. Luckily, the titanium replacement pocket clip from Etsy came with 2 black-coated screws, although they are still T6! C’mon, man! Sometimes it seems the world moves a bit too slowly.

Ergonomics

As mentioned earlier, the contoured, chamfered, smooth and thick scales with their relaxed finger grip grooves underneath fill the palm and make gripping the 273-03 very comfortable. However, the over-abundant jimping, which just about bloody everywhere on this knife’s handle, is a bit too coarsely cut and smoothed over to really help with getting a more secure grip. It’s more for aesthetics than function. Weirdly, there’s more jimping in the liners than there is in the scales! Benchmade forgot to add the jimping in the scales in the butt end of the handle! Where is your QC, Benchmade?

The area behind the front finger guard does serve as a decent finger choil, and the jimping there is admittedly better than having nothing at all, although if you want to see an example of excellently done, effective and very comfortable jimping, look no further than the jimping on the Viper Moon’s crowned blade spine. In addition, the Sibert speed holes help you feel where the position of the knife handle is in your hand.

Benchmade did a fine job in making the thumb studs accessible and comfortable to use to open the blade. Kudos to them for that. A lot of other knifemakers could improve their thumb stud-equipped knives by learning from this example. That said, those thumb studs are basically conical frustums (truncated cones) with a smooth lateral surface, and that smoothness interferes with the ease of doing a reverse flick. Geez, everything is a compromise!

Weight

The Benchmade Mini Adamas 273-03 is a hefty beast, but not overly so. However, when it comes to the oft-quoted desirable weight ratio of 1 oz. per 1” of blade length, this knife would be considered heavy. The blade length is a mere 3 3/8” (85.70 mm | 3.37″), whereas the knife’s weight was measured at 123.00 g (4.34 oz.). So much for ratios. Nevertheless, I really like how solid that heft feels in my hand.

Original Packaging

Benchmade does a consistent job with the boxing of its knives, although aside from the knife itself, what’s inside is super basic and totally inconsequential. The Black Class knife box is a heavy, rigid, full telescope paperboard box with a dense, dark charcoal, large-cell foam inset lining glued to the lower. The knife is enclosed in a small, black, satin, drawstring bag. Otherwise, all the box includes is marketing materials. No zippered pouch, no microfiber cloth, no stickers or anything else that would be cool. Meh.

Knife Karen Nitpicks

There is plenty to like in the Benchmade Mini Adamas 273-03 with the uncoated MagnaCut blade and the marbled carbon fiber scales. But it’s not a perfect specimen. There are a few criticisms I have to share. A few big ones, in fact. Wow, I mean some of these are major complaints! I demand to speak to the manager right now!

- The buried blade fuller is a useless feature if you are an inveterate reverse flicker. I mean, who isn’t, right?

- When you pull back on the AXIS Lock pin studs, if you don’t perfectly time the release, the blade swings down and immediately bounces back out as if the handle is filled with Flubber! Who knew? MagnaCut bounces!

- The side edges of the blade spine are just barely less sharp than those of Spyderco knives, and those are sharp as hell! Benchmade, chamfer your blade spines!

- The beautiful, marbled carbon fiber scales have small areas where the smoothing finish was not completely done right, and those rough spots break up the nice reflectivity of the scale’s surface finish. C’mon Benchmade! You gotta work on your quality control!

- The CF scales are visually compromised by the crappy, polished steel, button-top, T6 body screws. Hey Benchmade! Did you know that you can buy dark charcoal-coated, flat-top screws with T8 sockets that will both blend in with the scale color and finish as well as help users perform disassembly and maintenance on their knives? If you didn’t, here’s your heads up! But if you did, then you are just cheaping out on us!

- The hardness of the MagnaCut blade is promised to be 60-62 HRc. However, my testing revealed it was 59.28. Doing MagnaCut in 60-62 is not very impressive, but coming in with a low 59 HRc score is really disappointing.

- Some folks will see the 3 Sibert holes in the scales as a nitpick item. Not me, but I am a woman of the people, so here it is!

- The pivot face. Oh, the plain, boring pivot. Yes, it’s a captive pivot. Fine. But the design of the pivot face is so boring that wood boring beetles lose interest in boring the trees near Boeing, fall out and go boing off the tarmac. Yes, it’s that boring.

- The pocket clip is too long. I replaced it with a black Ti shortie and have never looked back.

- The most egregious issue we have here is the notorious and very real Butterfly tax. The cost of Benchmade knives is too damn high. Yes, every knife Benchmade sells is 100% American made. And setting the plasticky, cheap-feeling Grivory scales aside, they use mostly decent materials. But the huge quantities of knives they make give them a huge advantage with volume discounts for those materials. Their knives are not all that difficult, design-wise, to manufacture, and yet a lot of smaller American knifemakers who also use good materials and create sophisticated-designed knives who don’t get the volume discounts on those materials manage to offer nicer knives, more reasonable prices, or both. Ultimately, the question is this: Since there is little question that Benchmade knives are quality knives, are they a good value for the price? For many, they say no.

Price

The MSRP for the Benchmade Mini Adamas is $375. Yes, Three hundred and seventy-five dollars! You can a get a LOT of really impressive knives with MagnaCut and carbon fiber scales for that price, where the accessories, design features, and other details really bring home the value compared to Benchmade (and no, I’m not going to do a full inventory of the knife market right now to prove my point, but feel free to go to KnifeCenter and look at the Microtech, Hogue, Tactile, Zero Tolerance, American-made Spyderco, American-made Kershaw, Heretic, and even Buck – when they actually use a modern steel).

Now truth be told, no one BUT Benchmade themselves sells those knives for MSRP (and I hope no one pays MSRP!). The typical dealer discount allowed is MSRP-10%. This makes the Mini Adamas 273-03 a $337 knife at most places. In my case, I found a 20% off everything coupon last December at BlackOvis, where they had the 273-03 in stock. That brought it down to $300. Then I used a discount deal I got through PayPal Credit where I got $50 off my first purchase. That took the price down to $250. So, that’s when I pulled trigger.

But just 2 months later, I found the sexy Viper Moon, a MagnaCut and Fatcarbon scales knife with a titanium backspacer and pocket clip for $187 at Atlantic Knife. No coupon needed, that’s their price. And I like that knife better. Yeah, the Moon was made overseas, but we’re talking Maniago, Italy, not in Yangjiang, China. Western European labor costs are similar to that in the US.

So, it’s up to you to decide if the value of the Benchmade Butterfly tax is worth it. Make no mistake, I really like my Mini Adamas, but I can’t justify the regular cost for the value provided to buy another; not a new one, at least.

Verdict

The Benchmade Mini Adamas model 273-03, their top-of-the-line version of the manual-opening Mini Adamas line (they have since launched an auto version of this knife), is a very nice knife. It starts with the original Shane Sibert design, which originated back in 2011 and was created for both military and first responder personnel by being notably rugged, robust and durable. The original 960 mm (3.78”) folding blade was made of D2, and only in 2021 was the Adamas upgraded to using CPM CRU-WEAR. In that same year, the (slightly) smaller Mini Adamas was released, also in CPM CRU-WEAR. But 2 years later, in 2023, Benchmade joined the MagnaCut wave washing over the whole knife industry by releasing the 273-03, featuring an uncoated (well, it has a stonewash finish, but no Cerakote!) CPM MagnaCut blade and a beautiful, black, marbled carbon fiber handle.

The knife is impressive to hold, and the phosphor bronze washers break really well so that it becomes buttery smooth. The thumb studs have great clearance for easy accessibility, and of course, the AXIS Lock, especially after it breaks in, is very nice to use.

There are a spate of minor, niggling issues, of course. The MagnaCut blade isn’t hardened properly so it doesn’t benefit from the best qualities the steel has to offer. The scales have small areas where the carbon fiber was not completely finished. The aesthetics of the scales are diminished by the use of cheap, shiny, polished, button-top screw fasteners, and worse yet, they use inadequate, T6 sockets! Get real, Benchmade!

But the most egregious issue with Benchmade knives, not only the Mini Adamas, but more or less everything across the board in their product inventory, is the issue of the brand name upcharge, colloquially called the Butterfly tax, which is significant. Sure, Benchmade knives are 100% US-made, and there certainly are financial expenses to adhering to that policy. But compared to many other brands and models of US-made knives, Benchmade (and to a significant degree, Spyderco as well) are simply charging their customers quite a bit extra for nothing more than some perceived value associated with knives that are engraved with their brand name.

For many people, the true value of a Benchmade knife, when you consider the blade and handle materials used, their blade finish offerings, the sophistication, complexity and manufacturing challenges of their designs, the extras they include in the packaging, the quality of their craftspersonship (such as blade steel hardening, scale finishing and factory edge sharpness) do not add up. If we compare the price Benchmade charges for knives that are comparable to similar offerings from other manufacturers, a lot of people feel that Benchmade doesn’t provide the value the brand reputation would suggest (and for which we are paying). Those people believe the Butterfly tax is real and is very disappointing. Make no mistake, I very much like my Mini Adamas 273-03, but in terms of genuine value, it doesn’t come close to making the cut. ![]()