For a special occasion, I was recently offered a gift knife by a dear friend. They had heard me talk about the Civivi Vision FG in Ultem a few times, and they asked if that was what I’d like. For a micro-second, I considered mentioning the Kizer Militaw in S45VN with a mirror DLC finish and Purple Haze Fatcarbon scale inlays that I have been eyeballing from afar, but that’s a much more expensive (about 2.5 times as much!) knife and comparatively much harder to find as it sells out so quickly. I quickly regained my senses, realized a smart person never looks a gift horse in the mouth, and gratefully accepted the generous offer. (Thank you, my dear! ❤️)

Of course, I have really enjoyed the other Civivi knives I’ve acquired (reviews of some of those are scheduled to appear soon!), so I was fully confident in the brand reputation. And in the case of the Vision FG, it hit several marks for me in one knife.

Now that I’ve had it for a few weeks, let’s talk about this cool, innovative knife.

TL;DR

The Civivi Vision FG is a really nice example of how impressive a relative budget (< $100 – blame inflation, you know) knife can be. For the price, you get a 3.5” hollow-ground, Nitro-V blade. You get milled Ultem scales (I’ve been wanting to see what the hullabaloo is all about with this material). And you get the Snecx Superlock, a remarkable, ambidextrous, and robust blade lock. On top of it all, the Vision FG is a much bigger knife than it seems it should be. As a result, I have fallen for this amazing knife.

Pros

- Cool, innovative, and strong, spine-positioned Superlock

- Very sharp, very pretty, 3.5” hollow-ground, modified sheepsfoot reverse tanto Nitro-V blade

- Fully ambidextrous design

- Captive pivot

- Mostly comfortable *, hand-filling, near full-size knife

- Best iteration of Ultem scales I have seen

- Excellent value

Cons

- * The classically uncomfortable Civivi stamped pocket clip with the too-long, upturned, palm-poking, spoon-bill tip

- No flat spot under the scale contact point of the clip (although it is an ambi clip setup)

- Thumb studs are too close to the handle, complicating the reverse flick

- Scale dado indentations (on both sides) for the pocket clip are far too large, making unused side needlessly unsightly

- Unused side of clip indentation on scale is missing 1 screw (an empty hole!) and other screw doesn’t sit flush, also unsightly

- The blade’s claimed HRc hardness ratings were way high if my own tests are accurate

- Some people really don’t like the triple handle holes (although it’s not a big deal to me)

Tech Specs

Brand | Civivi |

Website | |

Manufacturer | WE Knife Co. Ltd. |

Origin | Yangjiang, China |

Model Reviewed | Vision FG C22036-5 |

Designer/Design | Snecx Tan |

Model Launch Year | 2023 |

Style | Folding Knife |

Lock Type | Superlock |

Opening Type | Manual |

Opening Mechanism(s) | 1. Dual, 3-stepped, domed cylindrical thumb studs |

Pivot Type | Brand-decorated, captive, flat steel pivot with T8 socket |

Pivot Mechanism | Caged Ceramic Ball Bearings |

Length Closed | 112.33 mm (4.42″) |

Length Open | 200.53 mm (7.90″) |

Weight | 116.06 g (4.09 oz.) |

Original Packaging | Heavy white, reverse tuck end (RTE) paperboard carton enclosing a black, lined zippered pouch, w/a good microfiber cleaning cloth, 2 stickers & multiple pieces of printed product use information, warranty information & marketing materials included |

Edge | Plain |

Shape | Modified Sheepsfoot Reverse Tanto |

Material | Nitro-V |

Claimed Hardness HRc | 59-61 |

Tested Hardness HRc | 55-56 |

Blade Length | 89.43 mm (3.52″) |

Cutting Edge Length | 79.47 mm (3.13″) |

Primary Bevel Angle | 3.5° |

Original Edge Angle | 16° |

Height | 27.41 mm (1.08″) |

Thickness | 3.01 mm (0.119″) |

Main Bevel Edge Thickness | 0.51 mm (0.019″) |

Thumb Studs Span | 12.04 mm (0.47″) |

Finish | Machine Satin |

Features | Hollow ground with very fine satin finish |

Grind | Partial full flat grind with flat only extending out 42.13 mm (1.66″) from ricasso |

Swedge | None |

Jimping | None |

Blade Markings | Show side: None |

Sharpening Choil | Large finger/sharpening choil |

On-Blade Opening Assists | Thumb studs |

Materials | Ultem |

Color | Yellow |

Scale Thickness | 4.03 mm (0.16″) including liner |

Scale Texture | Fine, diagonal lines |

Handle/Scale Features | Flat with 3 large holes through center along body and 1 hole to display inner workings of Superlock, cut edges |

Liners | Dual, full-length, stainless-steel liners, milled for weight reduction |

Stop Pin | Floating pin in handle |

Handle Length | 112.33 mm (4.42″) |

Closed Handle Height | 30.25 mm (1.19″) before Superlock |

Handle Thickness | 12.15 mm (0.48″) |

Pivot Center-to-Thumb Stud | 17.50 mm (0.69″) |

Pivot Center-to-Open-Knife Fulcrum (0.0 is balanced at pivot) | 23.90 mm (0.94″) |

Thumb Stud from Pivot Center | 44.5° |

Thumb Stud Tip to Scale Edge: | 2.97 mm (0.12″) / 2.97 mm (0.12″) |

Integral Handle | No |

Backspacing Type | Snecx calls the stainless-steel Superlock structure bar the backspacer, but there is 1 stand-off at the back of the knife |

Backspacing Material | Stainless steel |

Backspacer Color | Stonewash gray |

Backspacer Length | 70.67 mm (2.78″) |

Backspacer Features | A 3-cut, front-facing finely jimped nub 3mm proud of the spine, and there’s another set of 3 deeper, wider jimp cuts behind the nub for unlocking the blade |

Lanyard Mount | Standoff |

Pocket Clip | Stamped, deep-carry style |

Clip Material | Stainless steel |

Clip Color & Finish | Stonewashed steel |

Clip Placement | Ambidextrous, Tip-Up |

Clip Length | 49.30 mm (1.94″) |

Clip Length-to-Handle % | 43.89% |

Clip Features | Mounting screw access through top center cutout. Body of clip has 2nd center cutout, angles straight downward from top to tip, ending with spoon bill that rises quite high before leveling off. |

Fasteners | 1 T8 stainless steel body screw at back, with 2nd rear SS screw for mounting clip |

Who is Civivi?

Civivi Knives is the mid-tier brand of WE Knives (Sencut is the budget tier brand, and WE is the premium tier brand) and is located in Yangjiang, China. Civivi Knives was founded in 2018 to produce “a functional, utilitarian, EDC product line at more affordable prices” that use high-quality materials that look, feel, and perform well. From my experience, the quality of Civivi knives has been consistently excellent for their price point.

According to the Civivi website, the origin of their brand name comes from the Chinese characters “CI” (happiness) and “VI” (joy). So, say hello to the “Happy, Joy, Joy” brand of pocketknives!

Hmm. That does sound a bit familiar. I wonder if there is a connection…

Admittedly, that is how I feel when I get a new Civivi knife, so maybe so. But for what it’s worth, Google Translate says that “Happiness Joy Joy” translates to 幸福快乐快乐, which is pronounced “Xìngfú kuàilè kuàilè”. That doesn’t quite roll off the tongue as easily as “Civivi”, does it? But what does Google know about speaking Chinese? Does Google even know what 任和斯廷皮 means? Who knows.

Introducing the Civivi Vision FG

The Civivi Vision FG is the younger sister of the WE Knives Vision R, which came out a year earlier in 2022. Both knives share the same modified sheepsfoot reverse tanto-style blades of the same length & thickness and are both hardened to the same manufactured-claimed 59-61 HRc, despite using different blade steels. The handles are the same length as well, and both use the same, innovative, stainless-steel locking mechanism, but there are important differences between the WE and Civivi versions.

The WE Vision R knife features either a bead-blasted CPM 20CV or Damasteel blade featuring an elongated, pyriform oval-shaped opening hole, titanium fastening screws, and a spine-mounted, stamped-style Ti pocket clip, making the WE knife purely ambi without needing any alternations, but that also means both left & right-handed people will equally suffer the awkwardly positioned clip.

The WE knife apparently has a bit more milling in its liners, so it weighs 13.4g (0.47 oz) less than the Civivi, despite having titanium scales. For all the extra WE Vision R features, you can expect to pay between $263 – $277 (or $679 for Damasteel), which is 3x-to-8x the cost of its younger sister.

Now that you know what the older sister is like, let’s take a look at the younger, and frankly, more alluring sister, the Civivi Vision FG.

Details and Specs

The Civivi Vision FG, to my eyes, is a more refined design, perhaps even a version 2, of the WE Vision R knife. While the Civivi is quite a bit less expensive, it also resolved some of the common complaints about the WE knife. Let’s dig into the details and see if you agree that the Vision FG is a far better knife for both value and design improvements, even if the quality of the materials were lowered (it is a Civivi knife after all, not a WE knife).

Blade

The Vision FG features a beautiful, very high flat-grind, thin, hollow-ground edge, a very fine belt-satin-finished, modified sheepsfoot reverse tanto-styled blade crafted from American-made, ingot-formed, Nitro-V stainless steel. This differs from the WE Vision R’s higher-end CPM 20CV blade sporting better corrosion resistance and much better edge retention, but at a cost of much lower toughness.

Like most steels, Nitro-V has 2 of the 3 key properties down pat. (I discussed these properties in detail in the section 3 Key Properties of Knife Steel – Pick 2 from my previous knife review of the Mikov Kostka.)

Nitro-V’s toughness and corrosion resistance ratings, per the testing done by Dr. Larrin Thomas of KnifeSteelNerds.com, is very good at 7/10 (achieving better toughness than the particle metallurgy steels M390, Elmax, and S35VN).

However, the last key steel property is where Nitro-V falls short, rating only a 3/10 for edge retention. And given its thinned, hollow-ground edge, this isn’t great news at all for edge durability over time with heavy use. The key properties of the WE version’s 20CV is that it is stellar in corrosion resistance (9/10), above average in edge retention (6.5/10, nicely surpassing that of Nitro-V), but is surprisingly poor in toughness (3.5/10), despite being a particle metallurgy-formed steel.

Personally, I haven’t found the Vision FG’s Nitro-V blade edge to be lacking so far, but I admittedly have not yet put it through any brutal cutting tests. However, I promise you, as much as I like the guy personally, I won’t be like KnifeTuber Pete of Cedric & Ada and Outdoors, who tried to baton his Vision FG blade through ridiculously tough Aussie wood featuring long, stringy, entangled fibers. It didn’t go so well.

It turned his Vision FG’s Nitro-V blade into a rippled “exotic fruit prep tool” as he later called it. Oh, the humanity!

The Vision FG blade comes with a generous finger/sharpening choil, enabling you to choke up on the blade and press on the modified sheepsfoot reverse tanto angle change at the tip for precise draw cuts. The blade’s edge bevels were even and finely done. The blade does not feature a swedge, nor any crowning or jimping. The spine edges were just slightly chamfered to thankfully not be the pure, 90° sharp, skin-abrading beast that is so common on Spyderco blade spines.

Fresh out of the box, the Civivi was a very sharp, definitely benefitting from its narrow, hollow-ground primary bevel. The factory edge sharpening angle is a surprisingly robust 16° (likely in an attempt to bolster the steel’s weak edge retention), whereas the primary bevel came in at a mere 3.5° (yes, I finally got a laser goniometer!).

Kudos to Civivi for keeping the blade markings down to the barest minimum. On the show side of the blade, there’s nothing at all! Zip! Nada! Bupkis! The only way you’d know it was a Happy, Happy, Joy, Joy knife is due to their classic pivot face, the instantly recognizable sans serif C in polished steel on top of a black background, enclosed inside a very thin, polished steel circle. Very nice presentation!

The clip side of the blade does have some markings, though. The message “DESIGN BY SNECX” is clearly visible, engraved at the top back of the primary blade bevel. (I’ll talk more about Snecx later in this post.) And if you look very carefully, you will also see the steel name engraved in the tiniest text along the ricasso just above the apex of the blade choil.

I really find the blade shape to be visually appealing. But let’s discuss the shape’s name. The notion of calling this blade shape a “reverse tanto” is interesting, if not controversial. When I hear “tanto”, I always think of the Cold Steel-designed American tanto, which is a compound grind blade.

Yes, I know that a tanto doesn’t necessarily have to have a compound grind, but I will say that I’ve yet to see a reverse tanto with a compound grind (well, that is until I searched and found the Civivi Spiny Dogfish, but that’s not the style of compound grind I am speaking of).

Frankly, I’m inclined to call the Vision FG a modified sheepsfoot, “modified” because the cutting edge is not straight and parallel with the spine. But Civivi, in their wisdom, has deemed the Vision FG a reverse tanto, so I suppose we’ll (reluctantly) go with that… Maybe (or maybe not).

Blade Dimensions

The blade length is just a smidge over 3.5” (89.43 mm / 3.52″) with a cutting edge of 3 1/8” (79.47 mm / 3.13″). The blade height is just under 1 3/32” (27.41 mm / 1.08″) and its spine thickness measures at a slightly less-than-average 15/128” (3.01 mm / 0.119″). The hollow-ground, main bevel thickness measured just above the edge bevel came in at a very thin 0.023”.

HRc Rating

Civivi reports that their Nitro-V blades are heat-treat hardened to between 59-61 HRc. Coincidentally, this is the same hardness range WE claims for the Vision R blade in CPM 20CV.

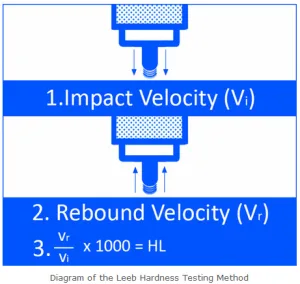

I recently got a Leeb Rebound Hardness Tester to run my own steel hardness tests. What is a Leeb rebound hardness tester? I thought you’d never ask!

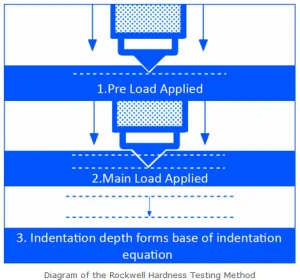

There are many mechanical methods for testing the hardness of materials such as steel. Most of the methods involve pressing a known harder material (diamond, tungsten carbide or hardened steel) into the softer material to be tested and measuring the resulting plastic deformation to determine how well the material resisted that deformation. These compression/indentation-based tests are often identified as destructive tests, as they leave notable pits in the steel. The list of such deformation testing methodologies includes Brinell, Knoop, Rockwell and Vickers, with Rockwell C being the most common scale for blade steel, and each of those have their own hardness measurement scales. The devices that perform these tests are typically large, stationary pieces of equipment that are expensive and provide excellent, accurate results.

Leeb testers, on the other hand, are typically considered non-destructive hardness testers, as they don’t measure compression deformation, but instead measure the rebound velocity (aka energy lost) from a known initial impact energy after impacting the tested material via the tester’s spring-loaded, tungsten carbide-tipped, impact “D probe”. The higher the rebound velocity, the higher the tested material’s hardness. Leeb testers take the average of a series of tests, typically 3, but that number can be incremented higher (I set mine up to take the average of 5 tests). The results are calculated on the Leeb HLD hardness scale.

How It Works

The Leeb testing procedure is quite simple. To set the D probe for a test, the user pushes down on an external collar from the end of the tubular handle toward the probe’s support ring that touches the test material. This cocks it, placing a load on an internal spring. When the button at the end of the probe handle is pressed, the load is released, propelling the probe inside the tube toward the support ring, which strikes the material. The movement of the D probe inside the tube generates a voltage in the tester due to a magnet and coil system inside the probe tube. After the strike, the probe’s rebound velocity energy is compared to the original striking velocity to get the differential measurement. You actually hear the physical rebound bounce for a second or 2, but that’s it. The tester records the data, and if additional tests are needed to get the average, it waits for you to re-cock the probe spring and run another impact test. Once all the needed impacts have been recorded, the average rebound energy loss is calculated, and the results are shown on the tester’s screen. It’s pretty easy!

The result of a D probe impact is far less destructive than the Rockwell’s 2-phase, compressive load test. However, it still leaves a minute, visible impact mark. The D probe’s impact marks are comparatively very tiny dots instead of the Rockwell test’s larger, deeper pits.

But that low-impact test has its drawbacks, too. To get the most accurate results from a Leeb tester, you need to follow a few rules. Otherwise, the tester will be incorrectly measuring the impact rebound. Here’s what to do:

- Ensure the steel’s testing surface is absolutely clean (no surface dirt or oil), smooth (no roughened surface features) and flat (no off-angles)

- Ensure the D probe is 90° perpendicular to the steel testing surface and remains that way through the rebound test (no wiggling! Press the probe’s test release button softly, slowly straight down)

- Reposition the D probe after each impact test so you are always testing a clean, flat spot

- Ensure you run enough impact tests so there's enough data to get a valid average

- Don’t go too fast in re-cocking the D probe, as it can release unexpectedly and generate an erroneous result (don’t ask how I know)

- If you make a mistake with any of the above, discard that test result or restart your testing process

All the above is why when doing Leeb D probe hardness tests on pocketknife blades, its best to disassemble the knife and conduct the tests on the blade’s flat, smooth tang section that, once done, will hide the tiny impact dots from view when reassembled.

Why Go with Leeb?

I understand that portable Leeb testers may report a hardness variance from certified reference hardness in the HRc scale by as much as -6% or more, but they are also reportedly much more accurate when rendering test results in their native Leeb HLD hardness scale, where the results are typically less than 0.67% off of reference hardness. Because of this, I now run my tests in the HLD scale.

But why did I buy one of these units when the test results data could be questionable? Well, have you ever priced a large, certified Rockwell Hardness Tester for Metal materials? They are crazy expensive. This is the biggest advantage of a portable Leeb Rebound Hardness Tester – it’s lower price of admission into hardness testing. Instead of costing in the 4-figures for the bigger, more destructive testers, you can buy a Leeb portable tester for a few hundred dollars. Personally, I’d rather have that leftover cash to buy some great knives (looking at you, Herman Knives!). Assuming I had such left-over cash reserves - which I don't. So, alas, no Herman knife for this Knife Karen, at least not anytime soon…

Challenge of Converting Leeb HLD to HRc

Let me tell you that getting the correct conversion data from Leeb HLD to Rockwell C was near impossible. Every conversion table I found online had different conversion values from every other! Compare for yourself at shapecut.com, ravnesystems.com, and machinemfg.com. It was so inconsistent that I had no idea which to believe!

However, I finally found a key document from the definitive source: ASTM International, a standards organization for materials and testing. The document provided the exact, complex equation for doing the HLD-to-HRC conversion, so I created my own Excel worksheet that calculates the HRc score from every HLD integer value (within the blade steel HRc range I wanted to see). What a frustrating chore this entire process was, but as usual, I learned something new, which made it worthwhile!

My new tester, which was repeatedly calibrated on a certified block of 791 Leeb-rated steel, indicated it has a consistent negative zero shift (the difference between the device’s measurement of the calibration block and the block’s actual certified hardness rating, by -4 points on the Leeb HLD scale – zero shift is explained quite well in this video by CBRx). This means that I will need to add +4 Leeb points to the averaged test result before I use my calculated table to get the most accurate HRc score. Look for more of my own comparative hardness test results in upcoming posts.

I used my new Leeb Rebound Hardness tester to collect the averaged hardness data from 5 rebound tests on the Vision FG’s blade tang measured on the Leeb HLD scale, which came back as 762. Then I corrected for the tester’s -4 zero shift points (now 766 HLD), and finally cross-referenced that score on my calculated HLD-to-HRc data table in Excel. The score? My calculated conversion revealed that my Civivi Vision FG’s blade hardness is 55.26 HRc. I ran a second set of HLD tests a few days later and that final score came back as 56.15 HRc. If this Leeb testing data is to be trusted, Civivi’s 59-61 HRc rating for their Nitro-V steel is quite a bit optimistic. Maybe that’s why Pete’s batoned Vision FG blade turned into a wiggly ribbon!

Opening Mechanisms

The Vision FG comes equipped with dual, barrel-shaped, 3-step-tipped thumb studs. This differs from the WE Vision R, which came instead with an opening hole. And according to Jared of Neeves Knives in his comparison review of these 2 knives, he liked the thumb studs much better! Of course, you can also use the Superlock release to open the knife!

Locking Mechanism

One of the most important traits of both the WE Vision R and the Civivi Vision FG is the fact that the enigmatic Malaysian artist, designer and knife enthusiast, Snecx Tan, designed these knives, and that he used a blade lock mechanism he invented back in 2018, the remarkable Superlock.

The Superlock is a long bar that sits along the spine of the knife handle in the form of backspacer bar. It’s pushed forward by means of an internal coil spring placed within a rear loop in the Superlock bar at the butt end of the knife. The tang of the Vision FG blade is semi-circular with a deep notch at the 2 o’clock position relative to when the show side blade is open and level. The front tip of the Superlock bar securely fills the blade tang notch when the knife is opened. This makes the Superlock especially robust and durable.

Near the front end of the Superlock bar is a bend with a raised finger nub that sits above the spine, which enables the user to pull back against the spring pressure to remove the bar from the notch in the tang, thus unlocking the blade.

The front of the Superlock bar then glides along the polished, semi-circular tang.

Once the bar’s front tip glides along the rotating blade tang to the deeper, secondary cutout notch that is also part of the finger/sharpening choil, the lock bar once again engages forward, which serves as a detent to close the knife blade in the handle.

It’s a beautiful design: smooth, fully ambidextrous, very secure, and a genuine joy to use. And most interestingly, Snecx decided to not patent his Superlock design, but instead gave it away to the public domain so any knifemaker could use it.

But I must add a word of caution: if you like to disassemble your knives to clean and maintain them, watch out! As soon as the Vision FG liner has been lifted, remember to remove the lock’s coil spring. It’s under compression pressure just sitting there, and if you mistakenly move the knife in a way to jostle the spring, it will absolutely jump out of the retention loop at the end of the Superlock bar and instantly travel to distant worlds unknown and unknowable (don’t ask me how I know).

Luckily, Civivi does sell an accessories parts kit, which includes extra body screws and several replacement springs. You need to email “sales at civivi dot com” and, per their FAQ page, include “knife name + exact model number + exact parts + quantity”. It costs a measly $5 via PayPal (to the aforementioned email address), and since the package ships directly from China, it’ll take between a couple and several weeks to be delivered. However, a springless Superlock is super-useless (don’t ask me how I know!), so save yourself a ton of trouble and frustration by carefully and immediately taking your Superlock spring out so it’s not lost. 😔

There are a few differences in the Superlock designs between the Civivi Vision FG and the WE Vision R. I think of the Vision FG as a version 2 upgrade from the WE Superlock. There are several implementation improvements done for the Civivi. First off, the Vision FG Superlock bar now has jimping on both the front face of the finger nub where you pull the lock bar back as well as down further along the top of the lock bar itself. In addition, the Vision FG Superlock bar itself is made from slightly thicker stainless-steel stock, which makes it more comfortable for your fingertips.

Lastly, the Superlock bar on the WE Vision R, by design, could actually be pulled back and away from the pivot of the knife. This was intended to provide better access to the locking area for easier maintenance, but many people reported that this unexpected, lock bar semi-disassembly caught them off-guard, and they really didn’t like that feature.

This “feature” was removed improved in the Vision FG by implementing another stop pin just behind the back loop of the lock bar to prevent it from being pulled back too far, and therefore no longer lifting up – only back. So altogether, the Vision FG Superlock is much more comfortable to operate, and it works intuitively – no weird surprises! And I can confirm that there is zero lock stick with the Vision FG. It’s super smooth.

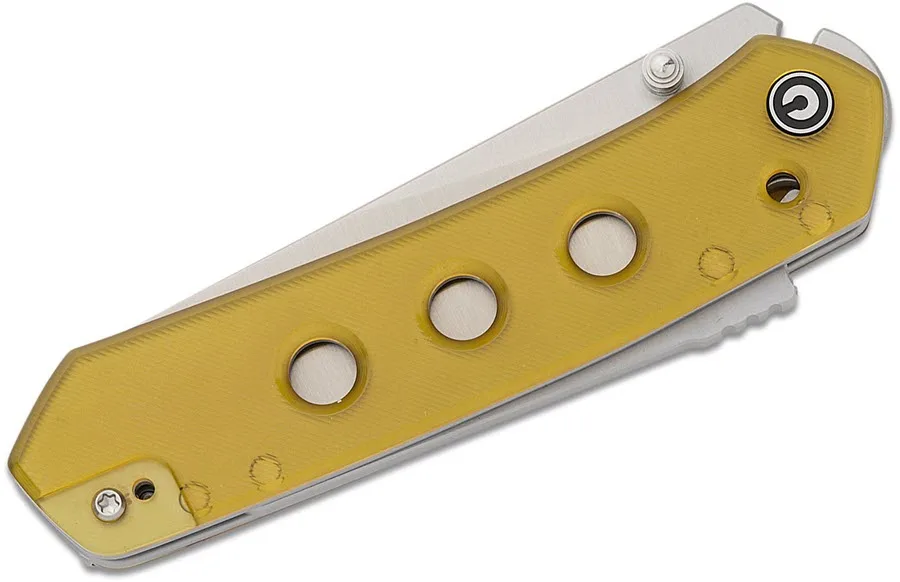

Knife Body & Scales

My Vision FG is model C22036-5, which includes the infamously translucent yellow Ultem scales on top of full-length stainless-steel liners. This is my first experience with Ultem, and I have been curious about what all the hubbub is about.

What is Ultem?

Ultem is the brand name product from Saudi Basic Industries Corporation (SABIC) for polyetherimide (PEI) thermoplastic resin, which was invented way back in the early 1980s. Ultem PEI is a well-established plastic that is available in many industrial grades. It can be melt-processed, injection molded, or even 3D printed. Ultem offers excellent material performance in machinability, elasticity resistance (stiffness and strength), scratch and stress crack resistance, high heat resistance (including air, flame, water and steam), chemical solvent resistance (such as fuels, coolants and lubricants), and resistance to both UV and gamma radiation. It’s commonly used as electrical insulators, sanitizable medical equipment, structural parts, and is approved for use in aerospace equipment. It even, on occasion, shows up as knife handle scales!

However, Ultem is a relatively expensive material, time-consuming for the manufacturer to process, and has very low colorability, so it’s usually offered in either yellow or amber in color. Despite all the positive features offered by Ultem, its color is the main source of the pejorative criticism, often derided by some knife critics as little more than “stabilized piss” or “the plastic covering from a chain smoker’s couch”. Yeah, that’s about right.

What made me select the Ultem scales of my Vision FG was that Civivi didn’t leave the surface smooth and plain. They milled very thin diagonal lines across the scales to help improve the grip tactility of the knife handle, and it also improved (in my very humble opinion!) the appearance of the scales. I have no regrets in selecting this tough, durable, albeit urine-tinted scale material.

Blade Handle Design

The scales of the Vision FG (and the Vision R as well) have 3 large holes that run down the length of the body of the scales and liners. The holes are part of the design’s easy-to-clean thinking (I read that the Vision R was actually designed to be a small, food-prep knife, but it clearly works as an EDC as well).

I have no complaint with the handle holes. The liners are milled for weight reduction, and you can see the blade when closed. But this is a controversial feature, as some people really hate that look. Shane Sibert is another knife designer known for putting large, see-through holes in his knife handles, and his design collaboration with Benchmade on their Adamas line of knives is a classic example of that. Sibert says he uses the handle holes to help him tell by feel how the knife is positioned in his hands, which makes a lot of sense. And hey, if you’re ever in a SHTF situation, you can use a bit of string to tie the opened knife through the holes onto a long stick to make a survival spear! As one would do…

Then there is the reason why these WE and Civivi Snecx knives are called the Vision: the Snecx vision hole. This smaller hole, positioned on the handle between the pivot and the finger nub of the Superlock, lets you see the Superlock bar tip interacting with the blade tang. You can see it when it’s locked up the blade, when it’s gliding along the semi-circular perimeter of the tang, as well as when it slips into the choil area when in the blade closed blade position. Of course, you can use this access to blow out accumulated dust and debris, if need be, or you can just admire the inner workings of the clever Snecx Superlock design.

The open blade rests against a floating stop pin. The pivot is classic Civivi; a branded, captive, steel pivot with a T8 socket. The open blade is secure; there’s no up-or-down nor side-to-side blade play, no pivot lash, no detent double-clutch, and the blade came centered. The blade rolls effortlessly around the pivot on caged ceramic ball bearings.

The Superlock’s structure bar serves as the Vision FG’s smooth-fit backspacer, which comes in at just a tad over 2 ¾” (70.67 mm / 2.78″) long. As previously mentioned, the stonewashed Superlock bar has a 3-cut, front-facing, finely jimped finger nub that stands 3mm proud of the spine, which offers the user slip-free access to easily pull back the lock bar to unlock the blade. If the user wants instead to simply press down and slide back the lock bar, there’s another set of 3 deeper, wider jimp cuts behind the finger nub so your finger won’t slip there, either.

Lastly, while there’s no specific lanyard/fob hole in the knife handle, there is a lone, rear standoff that can be used to attach a fob, which will make the last 3 remaining lanyard users in the world, Jordan, Kent, and Owen, sing Happy, Happy, Joy, Joy.

Handle Dimensions

Let’s talk measurement data.

The length of the Vision FG handle is 4 13/32” (112.33 mm / 4.42″), its height (before the Superlock bar begins to rise) was measured at 1 3/16” (30.25 mm / 1.19″), and the total thickness came to 15/32” (12.15 mm / 0.48″). The measured thickness of the knife’s handle scales, which includes both the Ultem and liners, was 5/32” (4.03 mm / 0.16″); however, just the Ultem scales themselves were 3/32” (2.54 mm / 0.1”).

I like to look at design considerations that pertain to the knife’s opening mechanism, as I suspect there are optimal measurements and ratios that make some knives so much easier to use (but I don’t yet know what they are, so I am recording these measurements in my knife reviews to see where, or even if, a positive correlated pattern emerges over time). Perhaps this will end up being another post sometime down the road.

The pivot center-to-thumb stud distance (where a higher measurement can mean less leverage for easy, fast opening) came to 11/16” (17.50 mm / 0.69″). The knife’s pivot center-to-open-knife fulcrum balance point, where 0.0 is balanced exactly at the pivot center, was 15/16” (23.90 mm / 0.94″). Additionally, the thumb stud-from-pivot center angle measured 44.5°. Lastly, the thumb stud tip-to-scale edge on both the show side and clip side of the Vision FG was an unnecessarily short 7/64” (2.97 mm / 0.12″).

And finally, the Superlock backspacer length was 2 25/32” (70.67 mm / 2.78″).

Hardware

The Vision FG pocket clip, unfortunately, is the typical Civivi stamped, stonewashed steel clip with the overly long spoon bill at the end. I know this design digs right into the center of my palm (this is not my first Civivi). Knowing this would be a problem when the order was placed for my Vision FG, I opted to drop the $13.50 to Amazon for the milled, plain, stonewashed titanium pocket clip before the Vision FG even came in.

The milled Ti clip is exactly the same length as the cheap steel clip, but the Ti clip is smooth, straight, level from top to bottom, narrower, and has a nicely rounded tip that does not bore itself deep into the very bone marrow of your metacarpals when you hammer grip the handle. And besides, it’s a Ti clip! And it comes with Ti fasteners! And best yet, those new Ti fasteners are T8 instead of the default T6 steel screws! It’s like Civivi is taunting us by making us pay extra to get the proper pocket clip! My only question is why this isn’t much better pocket clip offered by default? This Knife Karen wants to know!

Now I will acknowledge that the default steel clip is actually a deep-carry stamped clip, whereas the milled Ti clip is not. The difference in how much lower the knife sits in your pocket between the steel clip and the Ti clip is just under ½” (12.20 mm / 0.48”). If having a knife sit ½” deeper in your pocket is worth having that same pocket clip dig a hole in the palm of your hand, then you go ahead and own that. But you might want to invest instead in a crate of moleskin patches. Just sayin’…

One of the design elements I really appreciate in the Vision FG is the minimal number of fasteners used on the handle! That’s wonderful touch! The factory fasteners of the Vision FG are stainless steel. The pivot sports a T8 socket, as does the single body screw in the back of the knife. However, as mentioned earlier, the steel pocket clip fasteners have T6 sockets, whereas the upgraded Civivi titanium pocket clip comes with Ti fasteners that have T8 sockets. Getting this upgrade means I only need 1 Torx driver bit to do any work on the knife! What’s in your Torx driver?

Ergonomics

The Vision FG handle is a bit thicker than that of the Vision R because of the stainless-steel liners behind the Ultem scales (the Vision R comes with Ti scales without liners), so it has a better, hand-filling feel. The Vision FG, like its more expensive sister, has a large finger/sharpening choil, which gives you the ability to comfortably hold the knife either choked up for close-in, draw cuts or in a hammer grip for slicing. The diagonal line milling on the Ultem scales improves the grip over the more typical polished, smooth presentation of Ultem other knifemakers use.

The thumb studs, while comfortable to use, are not optimally placed relative to the knife scales; they are a bit too close. This means you have to press your thumb into the side of the thumb stud to get the leverage needed to open the blade. It’s certainly doable, but it’s not the free and clear access most people appreciate. The bigger challenge is doing a reverse flick due to the very tight squeeze. Again, it’s doable, but it’s not easy, and some concentration is needed to position all your fingers correctly to get that leverage.

The knife body could have been slightly sculpted back to provide that needed access, but no! Because the Civivi Vision FG is basically the v2 version of the WE Vision R knife design, which came equipped with a thumb hole instead of thumb studs, Civivi didn’t adequately address the differences in the access requirements between these 2 distinctly different opening methods, which is a genuine shame. It could have been an even better knife.

Weight

The Civivi Vision FG is a bigger knife than it might appear in the photos, so the weight is a bit heftier than you might expect (although it’s definitely not heavy). To me, it was a satisfying 116.06 g (4.09 oz.).

Original Packaging

Civivi does a decent job in packaging their knives. The Vision FG was shipped in a heavy white, reverse tuck end (RTE) paperboard carton enclosing a black, fleece-lined, zippered nylon pouch, which included a good microfiber cleaning cloth, 2 stickers, and included multiple pieces of printed product use information, warranty information & marketing materials. Other than the abundance of wasted paper for marketing materials that no one will read, I have no significant complaint here.

Knife Karen Nitpicks

To be honest, I really like my Civivi Vision FG. I like almost everything about it. Almost. Well, there’s a thing or two that could be improved. Hmmm, maybe a few things. Actually, there are a few things that are pretty annoying. Okay, that’s it. I need to speak to the manager!

- The default pocket clip is terribly uncomfortable. Civivi must already know this as it is a common complaint among knife reviewers. They even sell a very nice, milled Ti replacement clip so you won’t go to a 3rd party for the clip replacement. I don’t get why they still use that nasty steel clip. They must have gotten a helluva discount deal on a pallet or three of these penny-pinched, painfully piercing paw perforators.

- Continuing on about the abominable, stamped steel pocket clip, its fasteners are T6, but the much nicer Civivi milled titanium replacement pocket clip replaces those with nicer, Ti T8 fasteners! Why not give us this from the start? I feel a letter to the company president coming on.

- Another complaint about the pocket clip, but this time, it’s about the size of the clip cutout patch on the scales. It’s a great thing that Civivi made the knife ambidextrous-carry, but why mill out a dado cut the size of Montana? This huge recess isn’t very attractive on the clip side, but it’s a butt-ugly monstrosity on the show side. Isn’t your milling machine a bit more precise than this, Civivi? Or did your summer intern setup the CNC milling for this? Sheesh!

- One more pocket clip-related complaint. The cutout on the unused side has 2 screw holes, but only one is used for the rear standoff, which means there’s one screw hole that’s left empty on the show side! What’s with that, Civivi? Did you run short of body screws? And the one that’s there for the rear standoff doesn’t sit flush on the scale! This looks terrible!

- The thumb studs are too close to the scales, making the reverse flick an overly complicated maneuver to perform. Have you folks at Civivi ever heard of calipers? Gap gauges? Did you even try to reverse flick this knife in the office? Yeah, I can do it, but I have to actively think about positioning my fingers in a specific set of locations in order to do it. C’mon!

- The blade is claimed by Civivi to be at least 3 full HRc points higher than what I measured (twice!) on my own hardness tester. Now I am admittedly new to testing metal hardness, so I not super-confident in these results (even though I calibrated the tester and ran them twice!), but it bears further testing. Is this blade steel actually soft?

- Lastly, why doesn’t the Superlock have a captured spring? Civivi must certainly know that if someone removes the scales and liners from the Vision FG and even just gives a snarky look at the lock, the semi-compressed spring will suddenly and unexpectedly find a way to squirm out of the Superlock bar’s rear spring loop and launch its way to a nearby galactic wormhole and pass through to another dimension, where you will never, ever find it again (don’t ask me how I know!!). People! This is not acceptable! What’s the phone number of the CEO of Civivi? The Knife Karen has a bone to pick. Maybe I need to call Snecx as well and register a formal complaint (you know, for all the good folks who might suffer from this happenstance).

Price

The Civivi Vision FG with a Satin Finish Nitro-V blade and Ultem scales cost me $78.75. This is a remarkably good price for such a solid knife. I regard knives that cost < $100 to be part of our present day’s Budget Knife category (I blame inflation and the devalued buying power of the US dollar for this category’s higher range). To get a large, hollow-ground Nitro-V blade, high-quality scales, the robust, ambidextrous Superlock (the v2 edition, given the improvements made since the release of the WE Vision R the year before), ambi-adjustable pocket clip, all in a visually pleasing knife design that makes up the Vision FG, and is solidly in the Budget Knife territory (and remains so even if you do the recommended Ti pocket clip upgrade), this is an excellent value EDC knife.

Other models of the Vision FG feature either the Nitro-V or a Damascus [San Mai-style cladded] blade, all with dual thumb studs, the Snecx Superlock, stainless steel fastener screws, and the dubious Civivi stamped stainless steel pocket clip. The range of available scales offered include G10 and Micarta, or, if you go to KnifeCenter, you can get their special edition of the Civivi Vision FG, which has special materials upgrades, including a CPM-S35VN blade and Twill Carbon Fiber scales. The Civivi Vision FG prices range between $78 – $101 (except for KnifeCenter special version, which costs $139).

Verdict

The Civivi Vision FG is an overall winner. For less than $100 (and for the most part, far less!), you get a very nicely designed, surprisingly large (3.5”) blade made of either blackwash or satin-finished, hollow-ground, Nitro-V stainless steel or black-stained Damascus, presented in modified sheepsfoot reverse tanto style, a choice of full-length, liner-covered scale types (black canvas or dark green micarta, black, jade, or ivory G10, and that good ole, urochrome-colored Ultem). And don’t forget the cherry on top – thanks to knife designer Snecx Tan, it comes equipped with the robustly strong, easy-to-use, ambidextrous, spine-mounted and super cool Superlock. The high product value imbued in this budget category knife is superb.

I’ve really enjoyed using my Vision FG. It came very sharp right out-of-the-box. The Superlock is fun to use (after you get past trying to release a frame lock that isn’t there). I was pleasantly surprised at how big the knife was in my hand. Yeah, I can read the specs, but it still impressed me when I held it.

I bought the satin-finished blade with Ultem scales version. I was curious to see why Ultem is such a controversial scale material. Some people simply abhor Ultem, but the reasons seem to mostly be due to the color, which is reminiscent of urine in the toilet bowl. But many of these same folks will have no problem with eating bananas, lemons, pears, apples, pineapple, Manila mangoes, star fruit, yellow bell peppers, Chinese cabbage, Yukon Gold potatoes, sweet onions, wax beans, golden lentils, summer squashes, many winter squashes, golden beets, corn, some tomatoes and carrots, saffron, turmeric, ginger, beer, white wine, whisky (without caramel coloring), and so much more. But for some reason, the tough, heat-and-scratch-resistant thermoplastic resin known as Ultem still pisses people off. Go figure.

Now there are a few things that are imperfect with the Vision FG. The standard, stamped steel pocket clip has an overly long, upturned spoon bill end that is perfectly positioned to poke and pierce the palm of the most patient purchaser of this partially imperfect pocketknife. Luckily, Civivi sells a very nice, milled titanium replacement clip, but that is an additional $15 that should have been included in the original package. Some folks similarly loathe the triple handle holes. Luckily, I don’t. Also, the thumb studs are just too close to the scales. You have to work a bit harder to get the leverage for the standard thumb flip, and you really have to make a concentrated effort, at least in the beginning, to consistently do a successful reverse flick.

But in the big scheme of things, these are issues that can be addressed with either upgrades, developing Zen-like tolerance and patience, and/or adapting/upgrading your pocketknife hand skills. The Civivi Vision FG is an excellent quality, beautifully designed budget+ level pocketknife that is right at home in both the home/camp kitchen or in your pocket as your new EDC. ![]()